A wiring method of a printed circuit board

A printed circuit board and wiring technology, applied in the direction of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of inability to meet the requirements of high-frequency bus signal transmission and signal integrity, inconsistent dielectric constant of transmission lines, and signal delay Inconsistency and other problems, to achieve the effect of improving time delay inconsistency, improving impedance consistency, and reducing impedance fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 example

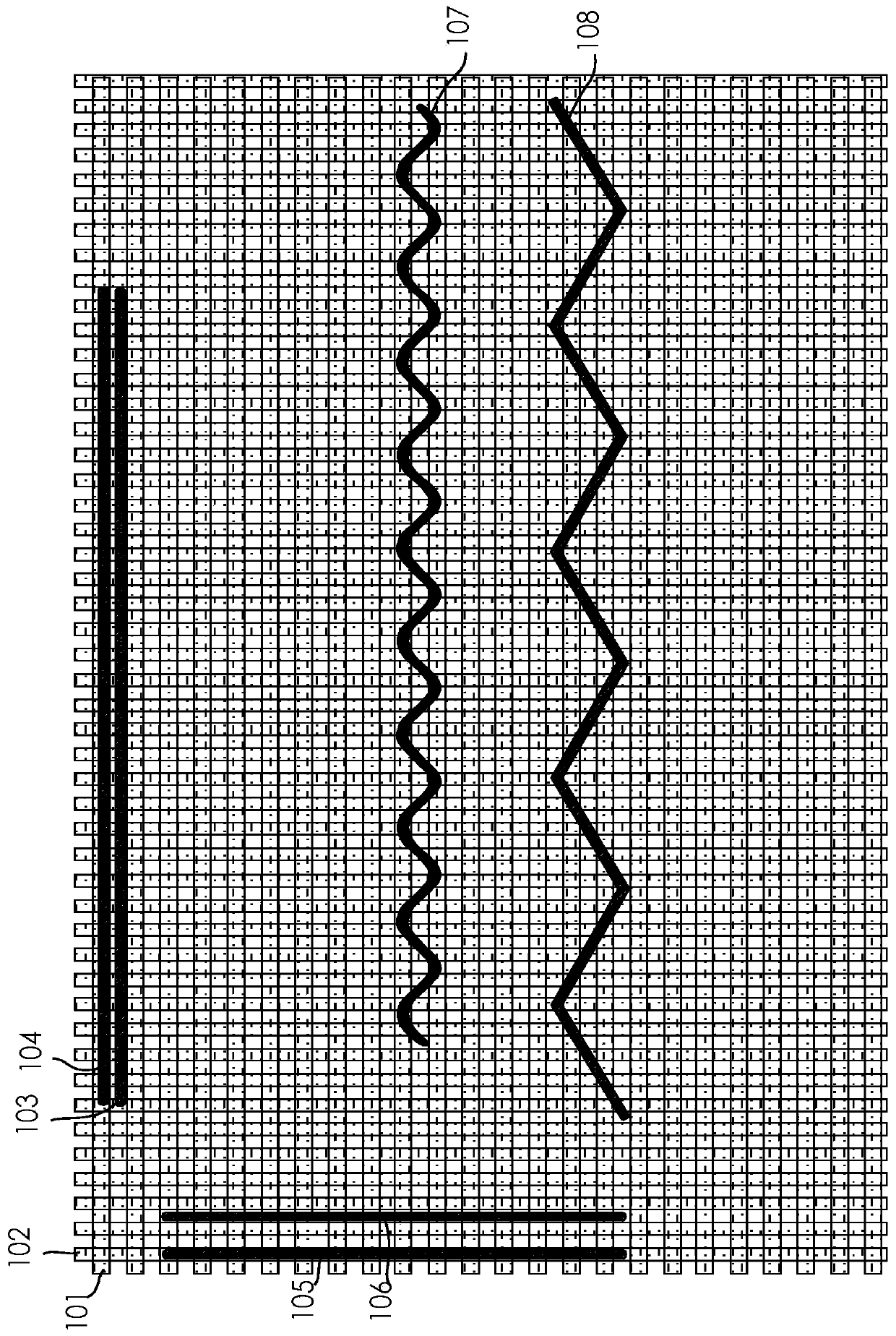

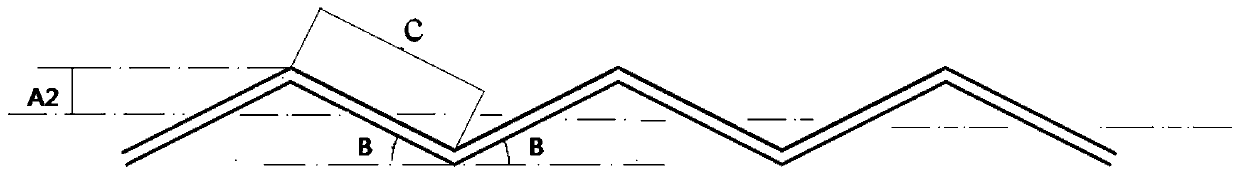

[0033] Such as figure 1 with image 3 As shown, the wiring method of the printed circuit board includes:

[0034] A transmission line 108 is arranged on the substrate. When the length of the transmission line 108 is greater than 1 inch, the transmission line 108 is in the shape of a symmetrical triangular wave curve. is B, where 0°<B<45°.

[0035] When wiring in the present invention, when the length of the transmission line 108 is greater than 1 inch, the transmission line 108 is arranged in a symmetrical triangular wave curve, so that the influence of the inhomogeneity of the PCB substrate medium on the transmission line 108 can be weakened, especially for high-speed PCBs. This wiring method can reduce the influence of the dielectric constant fluctuation of the dielectric layer on the impedance and signal transmission delay, reduce the impedance fluctuation of the same transmission line, improve the impedance consistency between different transmission lines, and significan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com