In vivo absorbable metal staple and preparation method thereof

A staple and metal technology, which is applied to the field of absorbable metal staples in vivo and their preparation, can solve the problems that the mechanical properties and biocompatibility requirements of staples cannot be met at the same time, and large-scale practical clinical applications cannot be obtained. Achieve the effect of ensuring biosafety and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

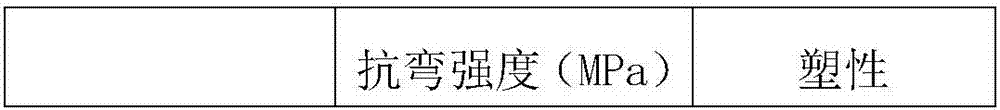

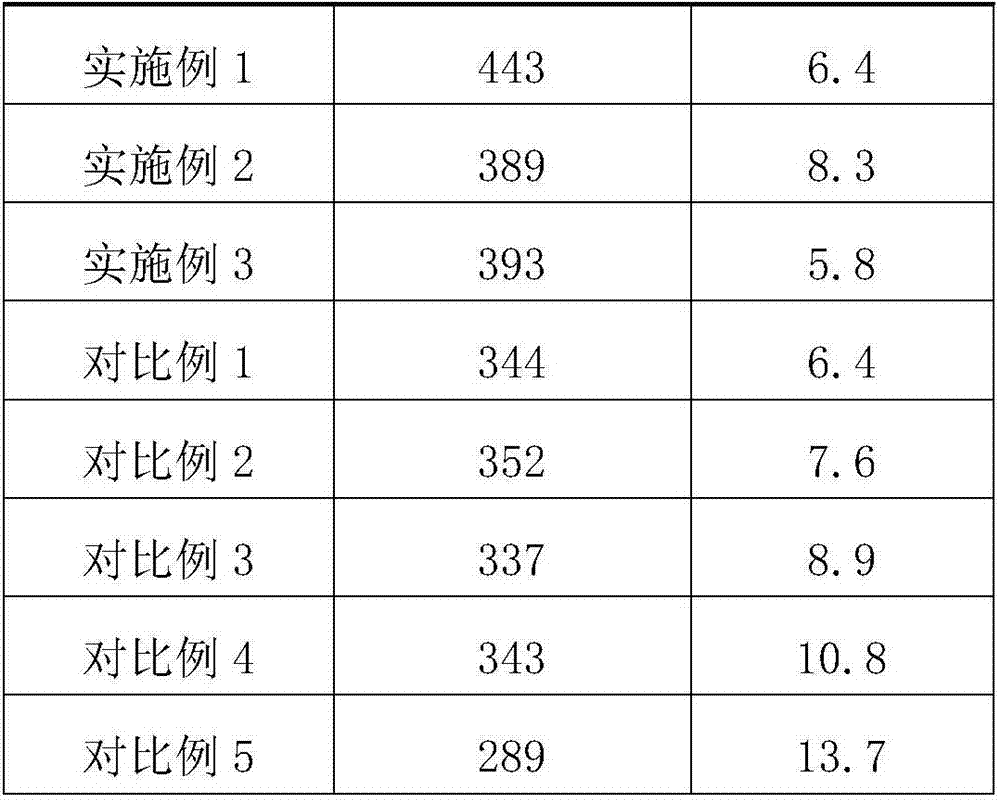

[0024] Under a protective atmosphere (the volume ratio of sulfur hexafluoride is 3%, the volume ratio of argon is 30%, and the rest is carbon dioxide), melt pure magnesium in a crucible at 750°C, and add 3.5% Zn, 0.5% Ca, 0.4% Fe and 3.3% Mn are cast into alloy ingots after being stirred and kept warm; put the alloy ingots into a heat treatment furnace, and perform homogenization treatment at 355°C for 12 hours; the alloy ingots after homogenization treatment are directly processed Hot extrusion, the extrusion ratio is 17, and the extrusion temperature is 250°C to obtain the primary billet; the primary billet is cut and turned to obtain the billet, and then quenched after solution treatment at 300°C for 8 hours to form the secondary billet ; Multi-pass continuous drawing of the secondary blank to form wires of different diameters. Wherein, in-situ oxygen-free annealing is performed when the cross-sectional area reduction rate is 40%, the annealing temperature is 200° C., and t...

Embodiment 2

[0026] Under a protective atmosphere (the volume ratio of sulfur hexafluoride is 3%, the volume ratio of argon is 30%, and the rest is carbon dioxide), melt pure magnesium in a crucible at 750°C, and add 2.2% Zn, 0.2% Ca, 0.3% Fe and 3% Mn are cast into alloy ingots after being stirred and kept warm; put the alloy ingots into a heat treatment furnace, and perform homogenization treatment at 355°C for 12 hours; the alloy ingots after homogenization treatment are directly processed Hot extrusion, the extrusion ratio is 17, and the extrusion temperature is 250°C to obtain the primary billet; the primary billet is cut and turned to obtain the billet, and then quenched after solution treatment at 300°C for 8 hours to form the secondary billet ; Multi-pass continuous drawing of the secondary blank to form wires of different diameters. Wherein, in-situ oxygen-free annealing is performed when the cross-sectional area reduction rate is 40%, the annealing temperature is 200° C., and the...

Embodiment 3

[0028] Under a protective atmosphere (the volume ratio of sulfur hexafluoride is 3%, the volume ratio of argon is 30%, and the rest is carbon dioxide), melt pure magnesium in a crucible at 750°C, and add 3.7% Zn, 0.7% Ca, 0.5% Fe and 4% Mn, after being stirred and kept warm, cast into alloy ingots; put the alloy ingots into a heat treatment furnace, and perform homogenization treatment at 355°C for 12 hours; the alloy ingots after homogenization treatment are directly processed Hot extrusion, the extrusion ratio is 17, and the extrusion temperature is 250°C to obtain the primary billet; the primary billet is cut and turned to obtain the billet, and then quenched after solution treatment at 300°C for 8 hours to form the secondary billet ; Multi-pass continuous drawing of the secondary blank to form wires of different diameters. Wherein, in-situ oxygen-free annealing is performed when the cross-sectional area reduction rate is 40%, the annealing temperature is 200° C., and the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com