Preparation technology of tylosin tartrate premix based on uniform mixing effect improvement

A technology of tylosin tartrate and preparation process, which is applied in the directions of medical preparations containing active ingredients, mixers, antibacterial drugs, etc., can solve the problem of uneven mixing and slow production speed of tylosin tartrate premix and other problems to achieve the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

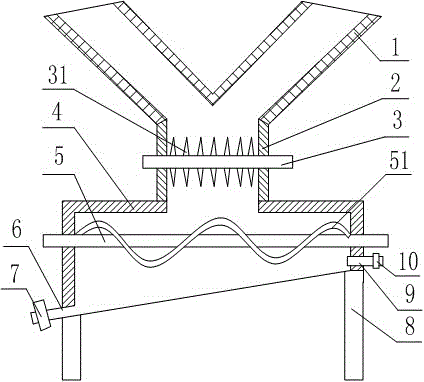

[0032] Such as figure 1 Shown, based on improving the preparation technology of the tylosin tartrate premix of mixing effect, comprises the following steps:

[0033] 1) Extraction of tylosin tartrate: using chloroform to extract back extraction containing tylosin tartrate

[0034] Take the liquid, dehydrate the extract of chloroform with anhydrous sodium sulfate successively, and distill under reduced pressure to remove the chloroform to obtain tylosin tartrate;

[0035] 2) Dry the extracted tylosin tartrate and prepare it into powder;

[0036] 3) Preparation process of tylosin tartrate premix: mix tylosin tartrate powder with auxiliary materials

[0037] After uniform mixing by the mixing device, bagging is carried out according to the specifications. The mixing device includes a V-shaped feeding port 1, and the discharge end of the V-shaped feeding port 1 is connected with a primary mixing chamber 2, and the primary mixing chamber 2 is provided with a first rotating shaft...

Embodiment 2

[0039] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the protrusion 31 is a smooth conical structure, and the circle

[0040] The apex of the cone structure is away from the first rotating shaft 3; the spiral structure 51 is a smooth tubular body. The bottom of the secondary mixing chamber 4 is sunken downwards, forming a groove in the middle, and the discharge port 6 is arranged at the groove; the V-shaped feeding port 1, the primary mixing chamber 2 and the secondary The mixing chamber 4 is made of hard aluminum alloy.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com