Linearly arranged artificial porous bone structure

A technology of linear arrangement and porous bone, applied in the field of artificial bone, can solve the problems that it is difficult to ensure the shape of the structure, and the porous titanium block structure is difficult to control and uncontrollable, and achieves considerable clinical medical prospects, good initial stability, and extensive The effect of bone ingrowth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

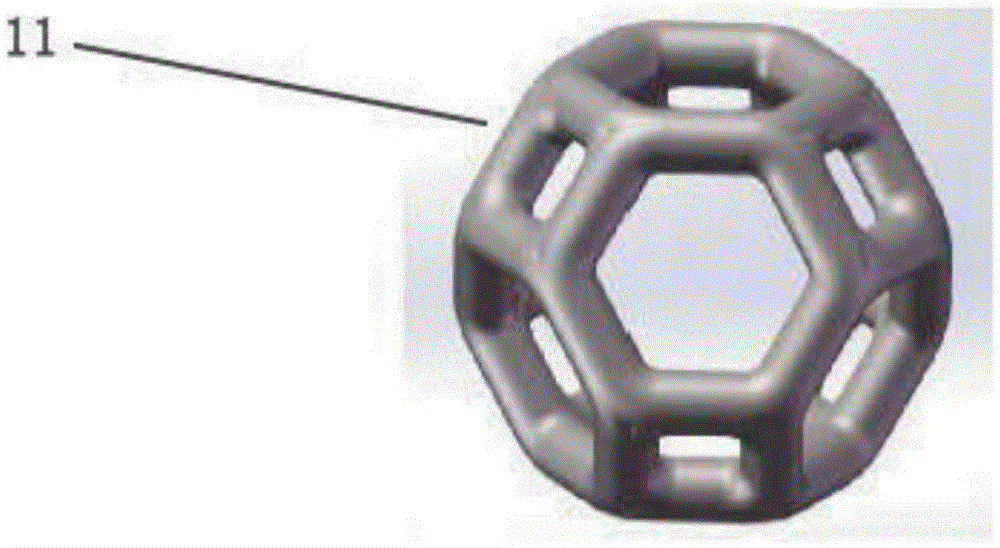

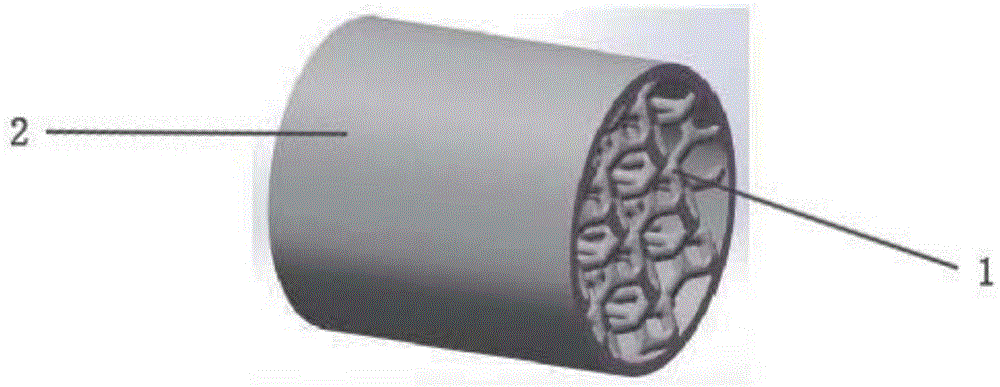

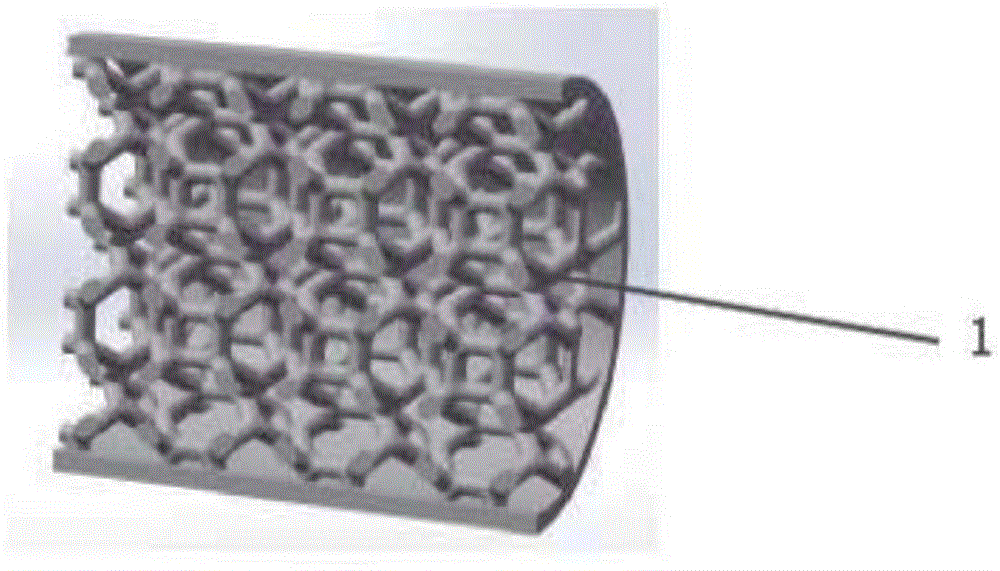

[0022] Such as figure 2 with 3 As shown, the artificial porous bone structure includes a shell 2 and a porous body 1 in the shell 2. The porous body 1 is formed by a plurality of grid units 11 linearly connected and arranged, and the grid units 11 are hollow and truncated. The thickness of the frame of the grid unit 11 is 220 μm, the pore size of the grid unit 11 is 1000 μm, and the porosity of the porous body 1 is 79.71%. The shell 2 is a cylindrical thickened entity. The grid units 11 are highly interconnected, and the porous body 1 presents a spatial grid shape. It is made of stainless steel as raw material, and is integrally formed by 3D laser selective melting.

Embodiment 2

[0024] The artificial porous bone structure includes a shell and a porous body in the shell. The porous body is formed by linearly connecting and arranging a plurality of grid units. The grid unit is a hollow truncated octahedron. The frame of the grid unit The thickness is 290 μm, the pore size of the grid unit is 750 μm, and the porosity of the porous body is 76.24%. The shell is a curved thickened entity seamlessly tangent to the outer contour of the human bone. The grid units are highly interconnected, and the porous body presents a spatial grid shape. Using titanium alloy as raw material, it is formed into one piece by 3D laser selective melting.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com