Drilling-reaming-dimpling integrated cutting tool

A technology for drilling, reaming, countersinking and cutting tools, which is used in drilling tool accessories, tools for lathes, and drilling, etc., can solve the problems of poor processing quality, short tool life, low hole-making efficiency, etc. Machining quality and burr suppression effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

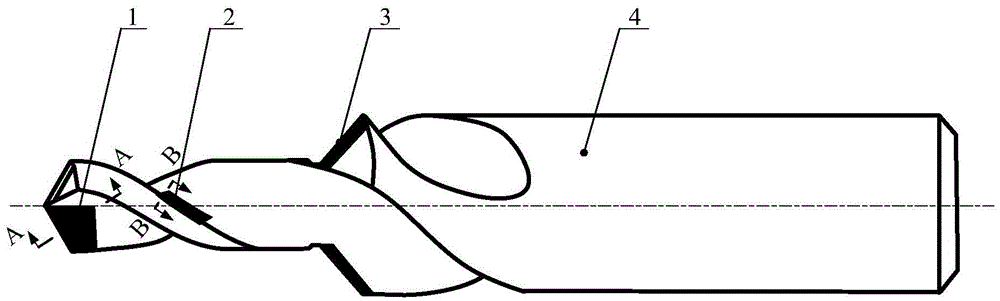

[0018] Such as figure 1 As shown, the integrated drilling, reaming and spot-sinking tool of the present invention is provided with a drilling part 1 , a reaming part 2 , a spot-sinking part 3 and a shank part 4 in sequence on the cutter body. Carbide is used as the matrix material, and PCD (polycrystalline diamond) is used as the working cutting edge material, which ensures the rigidity and strength of the tool matrix, and at the same time makes the cutting edge have high hardness and wear resistance, and improves the service life of the tool.

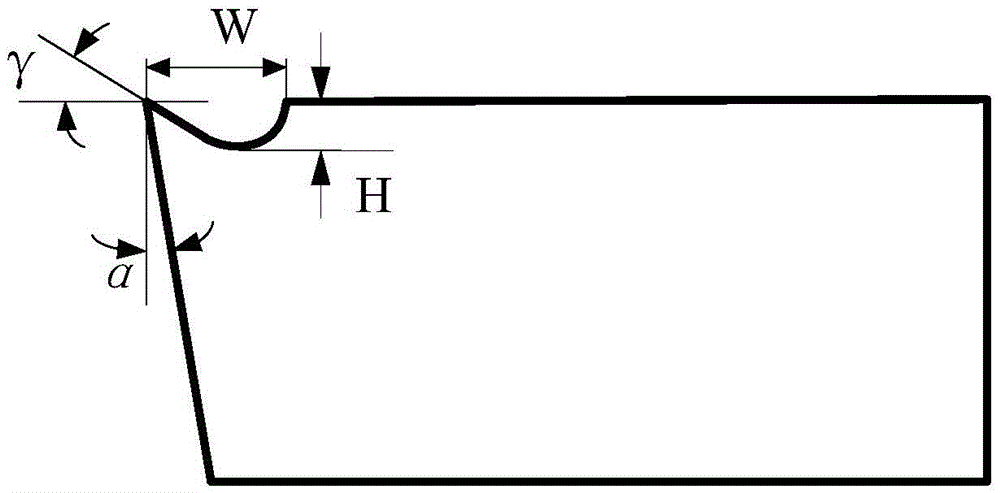

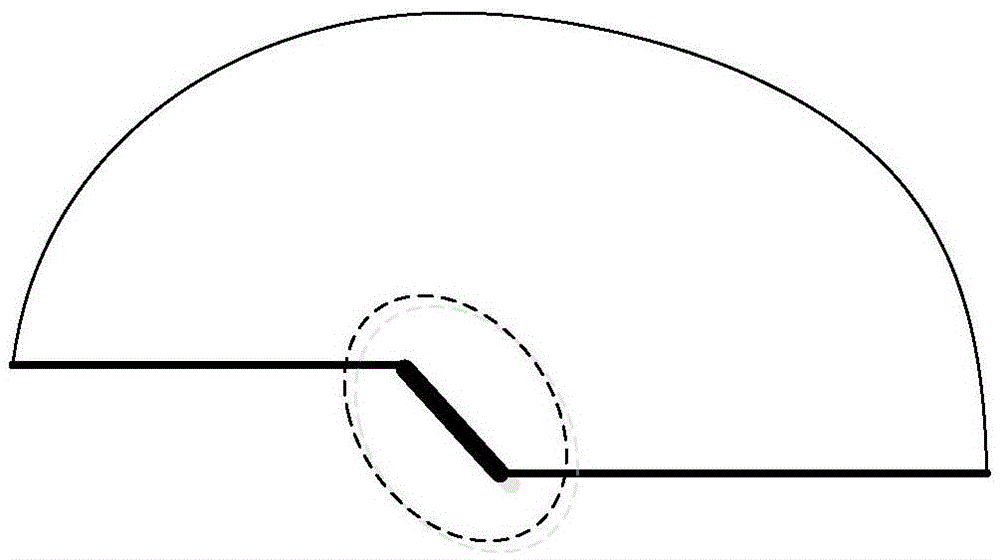

[0019] Drilling part 1 is composed of one chisel edge, two main cutting edges and two minor cutting edges. Considering the difficult machining of PCD material, the main cutting edge of the drill is set as a straight cutting edge, and the rake angle and back angle of each point on the cutting edge are The angles are all equal, the rake angle is 23°, and the relief angle is 13°, so as to reduce the cutting force and the friction between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com