Welding method for CO2 gas shielded welding for super-strength thick steel plate

A technology of gas shielded welding and welding methods, applied in welding equipment, welding/welding/cutting items, arc welding equipment, etc., can solve problems such as improving project construction cycle and cost, increasing welding labor intensity, and increasing process complexity. Achieve the effects of low welding cost, low labor intensity and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

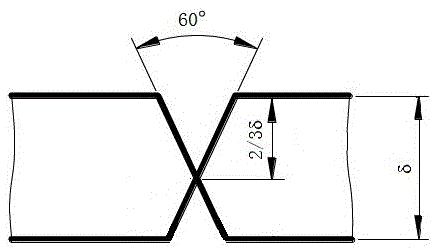

[0019] A CO for ultra-high-strength thick steel plates 2 Welding method of gas shielded welding. First process the groove on the ultra-high-strength thick steel plate to be welded after blanking, such as figure 1 As shown, the groove is an asymmetrical X shape, the angle of the groove is 60°, and the thickness of the upper groove is 2 / 3 of the thickness of the steel plate. CO 2 In the gas shielded welding method, the bottom layer welding and the filling layer welding are carried out in sequence, and then the nondestructive testing of the weld seam and the mechanical performance testing of the welded joint are carried out by ultrasonic waves. In this embodiment, no preheating is required before welding, interlayer temperature control is not required during welding, and slow cooling is not required after welding.

[0020] The bottom layer welding in this embodiment adopts 500MPa level welding wire ER50-6, the welding wire diameter is 1.2mm, and the bottom layer thickness is 5...

Embodiment 2

[0026] A CO for ultra-high-strength thick steel plates 2 Welding method of gas shielded welding. First process the groove on the ultra-high-strength thick steel plate to be welded after blanking, such as figure 1 As shown, the groove is an asymmetrical X shape, the angle of the groove is 60°, and the thickness of the upper groove is 2 / 3 of the thickness of the steel plate. CO 2 In the gas shielded welding method, the bottom layer welding and the filling layer welding are carried out in sequence, and then the nondestructive testing of the weld seam and the mechanical performance testing of the welded joint are carried out by ultrasonic waves. In this embodiment, no preheating is required before welding, interlayer temperature control is not required during welding, and slow cooling is not required after welding.

[0027] The primer welding in this embodiment uses 600MPa-grade welding wire ER60-6 with a diameter of 1.2mm and a thickness of 2-5mm for the primer; the filler lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com