Dual-station discharge mechanism

A dual-station, station technology, applied in the direction of conveyor objects, transportation and packaging, packaging, etc., can solve problems such as the impact of the production efficiency of the assembly line, the blockage of the machine tool discharge channel, and the large amount of product transfer. The effect of taking efficiency, improving processing efficiency and smooth discharging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

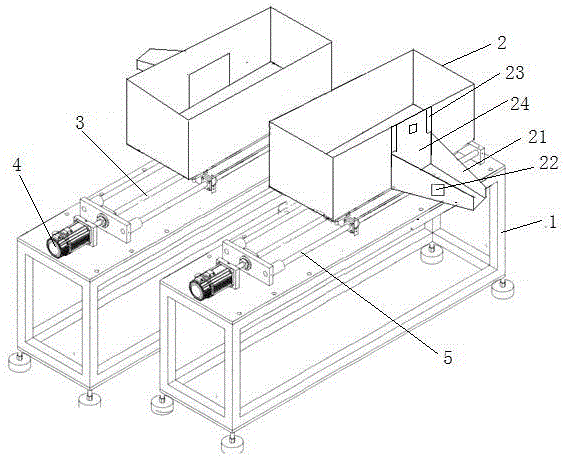

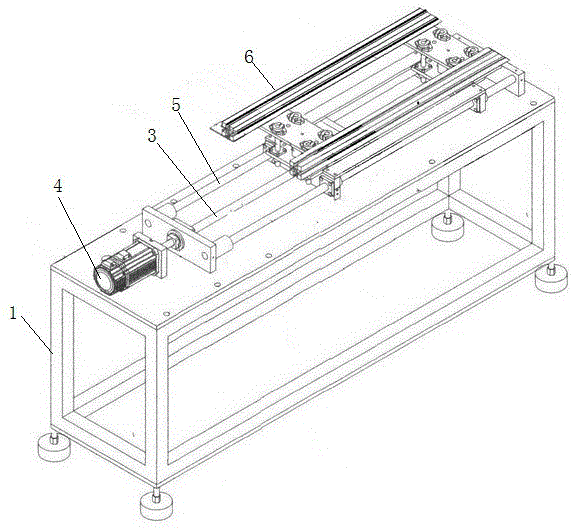

[0018] combine figure 1 with figure 2 In the illustrated embodiment, the moving track of the silo is two guide rails 5 parallel to the screw rod 3 and arranged on both sides of the screw rod, and the bin mounting frame 6 is slidably connected to the two guide rails 5 . The arrangement of double guide rails can make the movement of the material bin 2 more stable. The screw mandrel 3 is connected to the output shaft of the driving motor through a coupling, and the driving motor 4 can be selected from an existing stepping motor.

[0019] The silo 2 is provided with a discharge port, the discharge port is provided with a discharge baffle 24, the two sides of the discharge port are provided with a retaining bar 23, and the both sides of the discharge baffle 24 are snapped into the retaining bar 23 and the receiving bin 2. between the walls, and can move up and down to cover or keep away from the outlet.

[0020] When the discharge baffle 24 is opened, in order to make the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com