Method for efficiently and rapidly reducing viscosity of polymers in oil field polymer-bearing wastewater and ternary composite flooding water

A ternary composite, polymer technology, applied in water pollutants, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult treatment process, high re-injection pressure, and high viscosity, and achieve low operating costs and reduced costs. The effect of fast sticking speed and simple medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific implementation mode 1: An efficient oilfield polymer-containing sewage and a method for quickly reducing the viscosity of polymers in ternary compound flooding water according to this embodiment is specifically prepared according to the following steps:

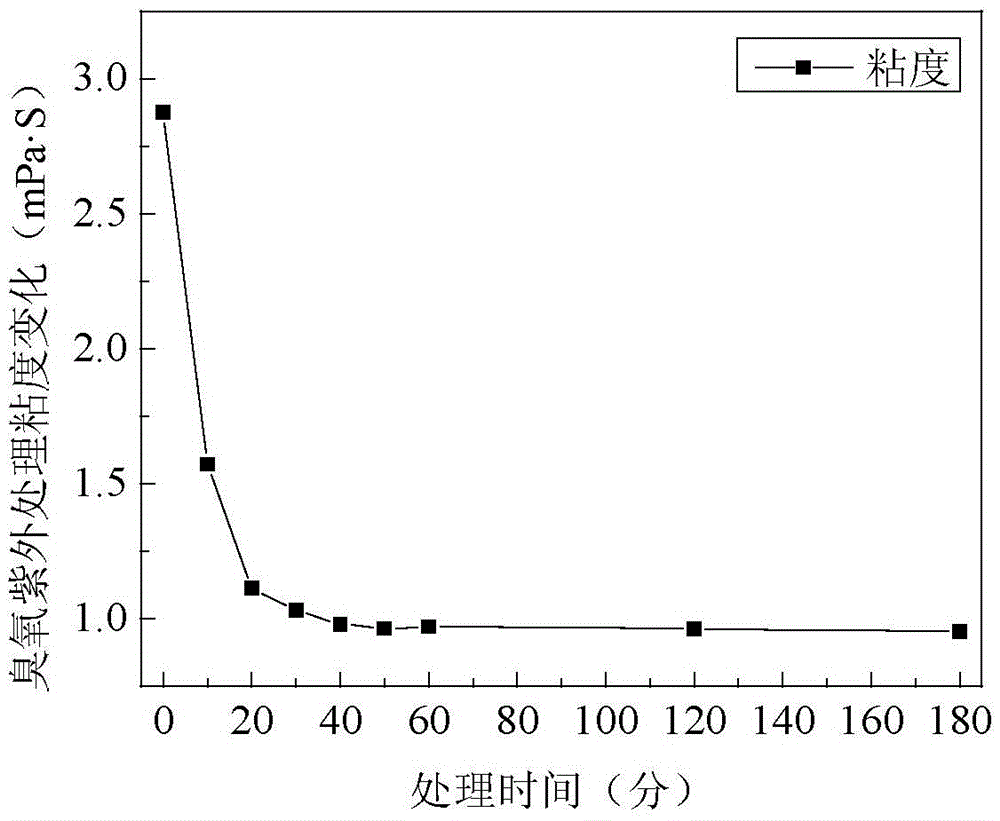

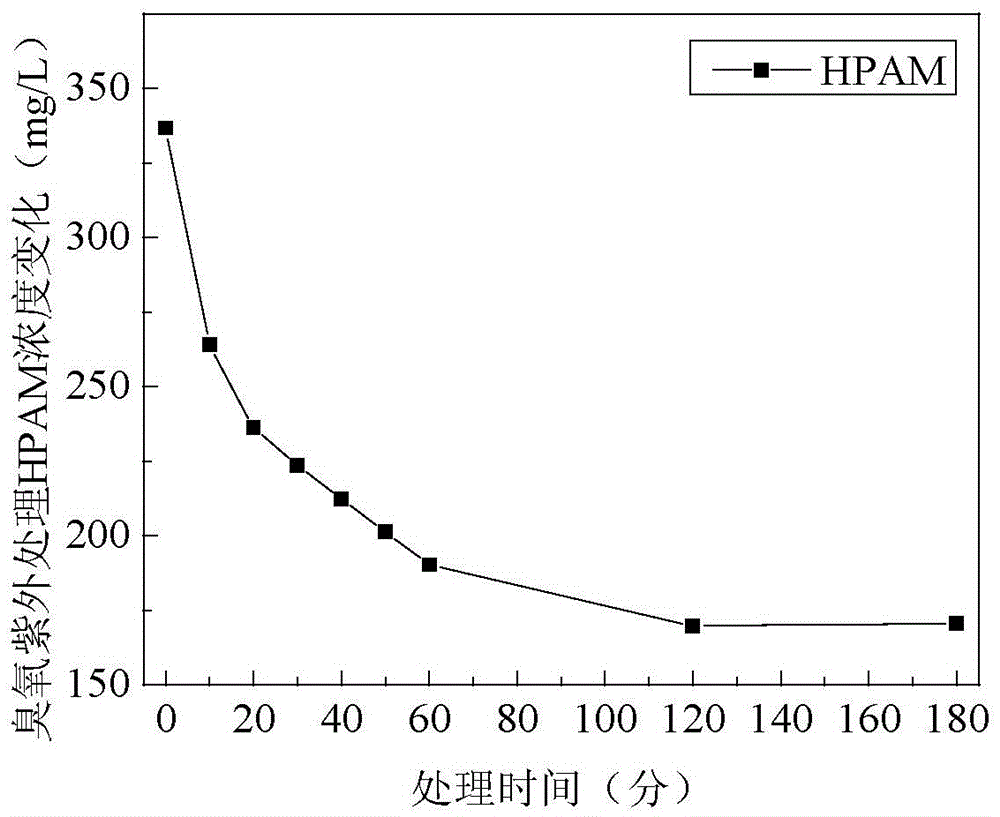

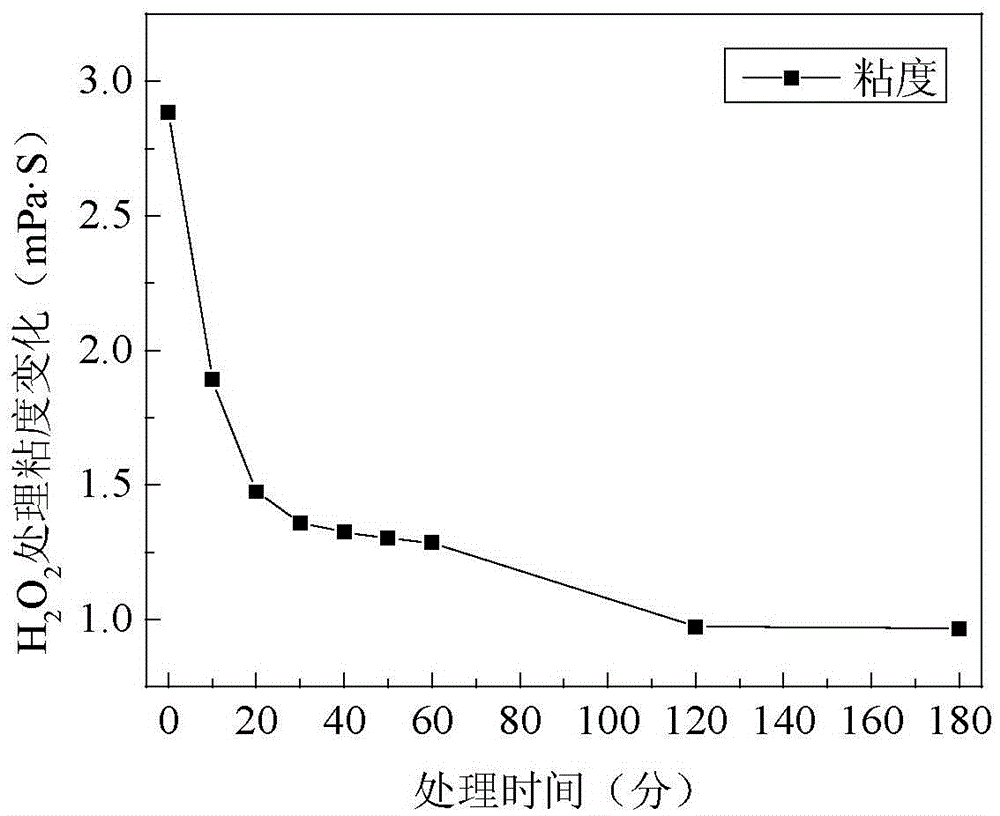

[0023] Step 1. Utilize the ozone ultraviolet combination process to treat the poly-containing sewage. The poly-contained sewage is passed into the reactor with the ultraviolet lamp embedded in it at a flow rate of 1-5m / s, and the concentration of 33.3mg / s is passed into the reactor. After 20min to 30min of L-40mg / L ozone, the viscosity of the polymer-containing sewage is less than 0.2E.Pa.s, and the operation is stopped to meet the requirements for rapid viscosity reduction of the polymer-containing sewage; among them, the ultraviolet lamp tube of the reactor (China Haining Yi Kangda Lighting Company) has an emission wavelength of 254nm and a power of 40w. Polymer-containing sewage is oilfield polymer-containin...

specific Embodiment approach 2

[0032] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 1, the poly-containing sewage is passed into the reactor embedded with ultraviolet lamps at a flow rate of 2-4 m / s. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0033] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 1, ozone with a concentration of 35 mg / L-38 mg / L is injected for 20 min-25 min. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com