Photodiffusion particles, preparation method thereof, thermoplastic photodiffusion material comprising photodiffusion particles and application of photodiffusion particles

A light-diffusing particle, thermoplastic technology, applied in the field of thermoplastic light-diffusing materials, can solve the problems of poor covering power of silicone microspheres, complicated preparation process, low haze, etc., and achieves enhanced covering effect, less impact on toughness, and improved whiteness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1-A5

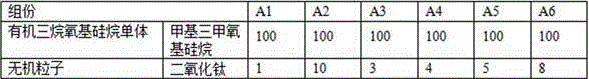

[0046] Embodiment A1-A5: Preparation of light diffusing particles

[0047] Disperse the inorganic particles in the aqueous solution containing the dispersant according to the formula in Table 1, stir with a stirrer for 20min-40min, adjust the pH value to 4.5-5.0, add the organotrialkoxysilane monomer, mix to obtain the hydrolyzate , continue stirring with a stirrer for 20min-40min, adjust the pH value of the hydrolyzed solution to 8.5-9.0, react for 3h-5h, filter, wash, and dry to obtain light-diffusing particles.

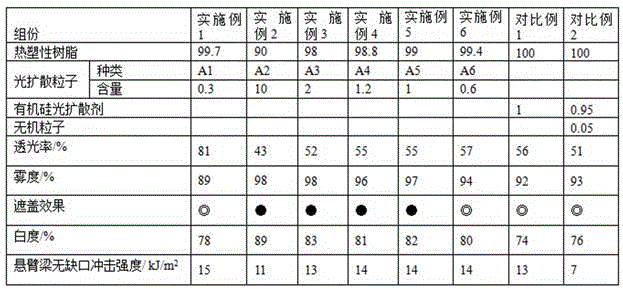

[0048] Table 1 Contents of each component of light-diffusing particles (weight ratio)

[0049]

Embodiment 1-5

[0050] Embodiment 1-5: Preparation of thermoplastic light diffusing material

[0051] According to the formula in Table 2, the light-diffusing particles prepared in Examples A1-A5 and the thermoplastic resin were fully mixed through a high-speed mixer, and a co-rotating twin-screw extruder was used to melt and blend one-step extrusion (extrusion temperature: 170 °C-250 °C) to obtain a thermoplastic light-diffusing material; the performance indicators of the prepared thermoplastic light-diffusing material are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com