Secondary battery and production method thereof

A secondary battery and cell technology, applied in the field of lithium-ion batteries, can solve the problems of insufficient adhesion and poor thermal conductivity, achieve good thermal conductivity, improve overcharge safety performance, and avoid the effect of detaching from the surface of the cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

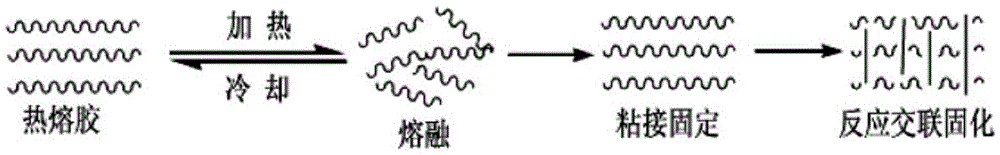

[0086] The preparation method of the heat-conducting adhesive of this application is as follows: in a moisture-free inert gas protection environment, heat the raw materials, add heat-conducting fillers, stir and disperse evenly, and then seal.

[0087] As an improvement of the secondary battery of this application, the area of the thermal conductive glue is 1mm 2 ~500mm 2 , the thickness of the heat-conducting adhesive is 0.05-5 mm.

[0088] The present application also relates to a preparation method of the secondary battery. Applying heat-conducting glue on the safety component, or applying heat-conducting glue on the battery cell, and applying a pressure of 0.1-100N to make the safety component and the battery cell adhere firmly. Preferably, the operating temperature of the thermally conductive adhesive is 150-200°C.

[0089] In this application, the application method of thermal conductive adhesive can be coating, coating, sticking, placing, etc.; the coating method ca...

Embodiment 1~9

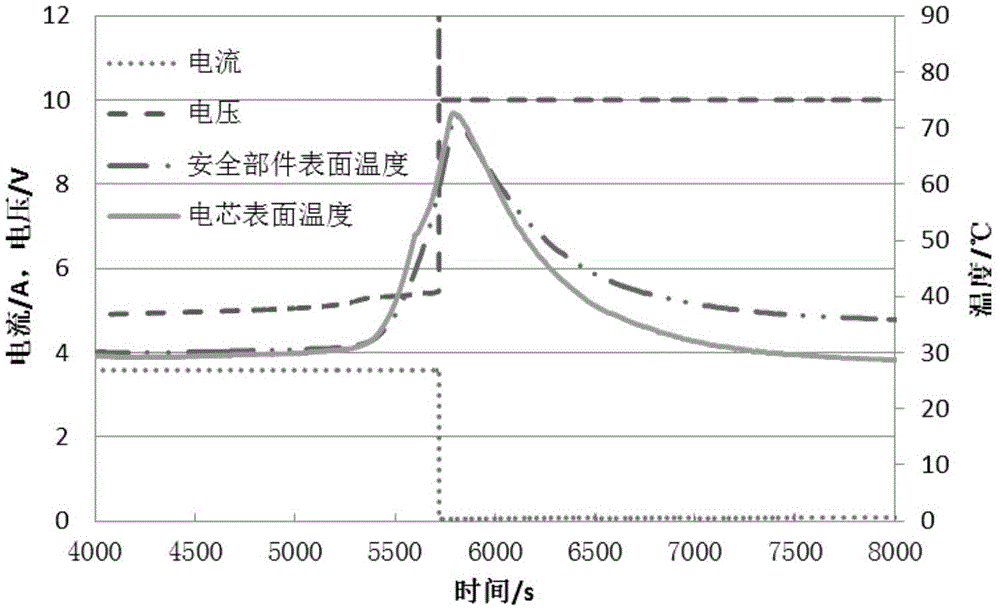

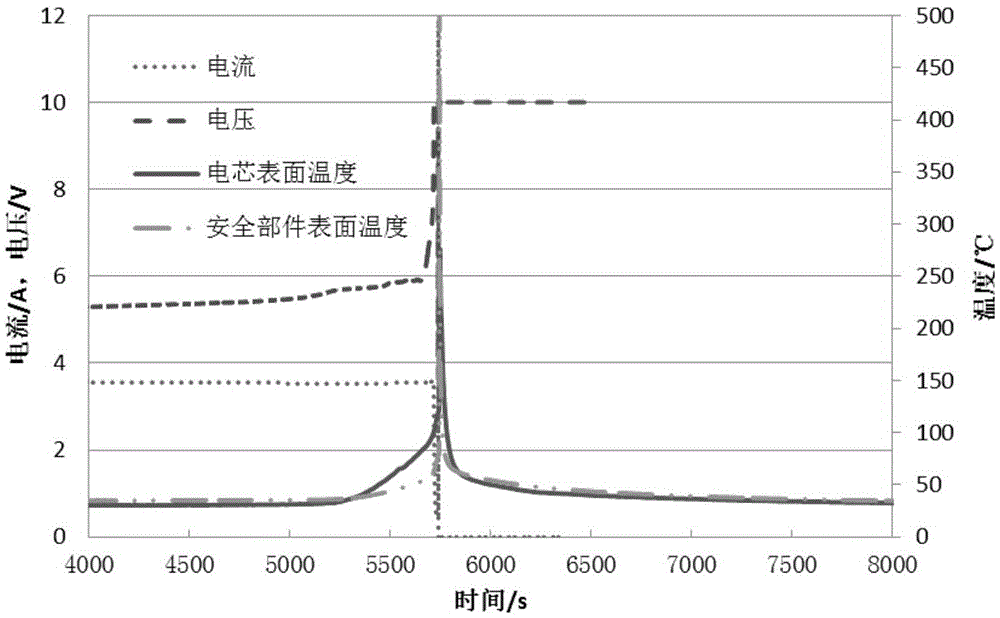

[0095] Prepare a thermally conductive adhesive according to the hot melt adhesive and conductive filler shown in Table 1, and apply the prepared thermally conductive adhesive between the battery cell and the safety component, and test the performance of the battery cell.

[0096] Preparation method of heat-conducting adhesive: In a moisture-free inert gas protection environment, heat the raw materials, add heat-conducting fillers, stir and disperse evenly, and then seal.

[0097] The preparation method of the battery: apply heat-conducting glue on the safety component, or apply heat-conducting glue on the battery core, and apply a pressure of 0.1-100N to make the safety component and the battery core adhere firmly. Preferably, the operating temperature of the thermally conductive adhesive is 150-200°C.

[0098] Table 1:

[0099]

[0100] The properties of the thermally conductive adhesives of Examples 1-9 and Comparative Examples 1-3 are shown in Table 2:

[0101] Table 2...

Embodiment 2

[0113] Prepare a thermally conductive adhesive according to the hot melt adhesive and conductive filler shown in Table 4, and apply the prepared thermally conductive adhesive between the battery cell and the safety component, and test the performance of the battery cell. The preparation method is the same as in Example 1.

[0114] Table 4:

[0115]

[0116]

[0117] The properties of the thermally conductive adhesives of Examples 10-30 are shown in Table 5:

[0118] table 5:

[0119]

[0120] The performance of the detected battery is shown in Table 6:

[0121] Table 6:

[0122]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com