Realization Method of Car Body Lightweight Structure Based on Particle Swarm Optimization Algorithm

A particle swarm optimization and implementation method technology, applied in design optimization/simulation, calculation, special data processing applications, etc., to achieve the effect of improving optimization capabilities, reducing time-consuming, and improving global optimization capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

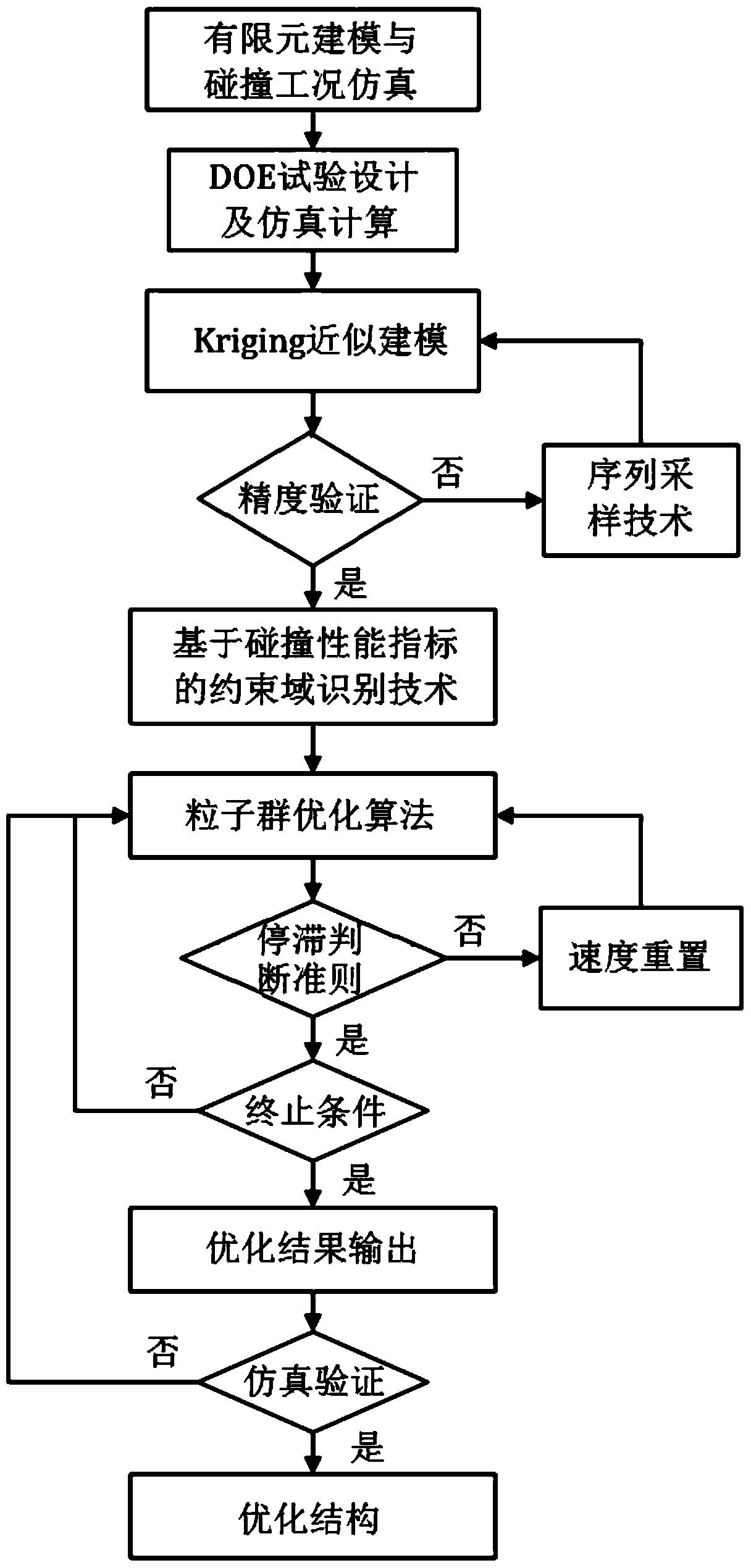

[0037] Such as figure 1 As shown, this embodiment includes the following steps:

[0038] Step 1, such as figure 2 As shown, using Hypermesh and Primer as the pre-processing software platform, and LS-DYNA as the solver, carry out high-precision body finite element modeling, DOE test design and simulation analysis on the specified car body, and obtain the vehicle finite element model and 40% Offset crash simulation model.

[0039] The vehicle finite element model includes 940224 units and 892192 nodes, of which: 940224 units include 855608 surface units, 12793 hexahedron solid units, 502 tetrahedron solid units and 11850 beam beam units, 855608 There are 12887 (1.5%) triangular elements in the surface elements, which proves that the accuracy of the vehicle finite element model is reliable.

[0040] Such as image 3 As shown, the simulation analysis refers to: According to the requirements of "Occupant Protection in Frontal Offset Collision of Passenger Cars" (GB\T-20913-200...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com