Centralization method for representing behavior uniformity of droplet clusters in direct contact boiling heat exchange process

A technology of boiling heat transfer and droplet group, which is applied in image data processing, instrumentation, electrical digital data processing, etc., can solve the problems of few practical applications and complex devices, and achieve the effects of reducing economic losses and measuring uniformity accurately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Test design and test platform construction

[0028] In this example, the ORC direct-contact steam generator test platform was built, and four test parameters were selected for the orthogonal test, namely, the liquid level of the continuous phase heat transfer oil in the ORC direct-contact evaporator, the initial heat transfer temperature difference, and the working fluid flow rate and heat transfer oil flow rate. There are three variables for each parameter; according to the orthogonal test table, this test uses an orthogonal test with 4 factors and 3 levels. See Table 1 for the L9(34) orthogonal test factor level table and Table 2 for the experimental design scheme.

[0029] Table 1

[0030]

[0031] Table 2

[0032]

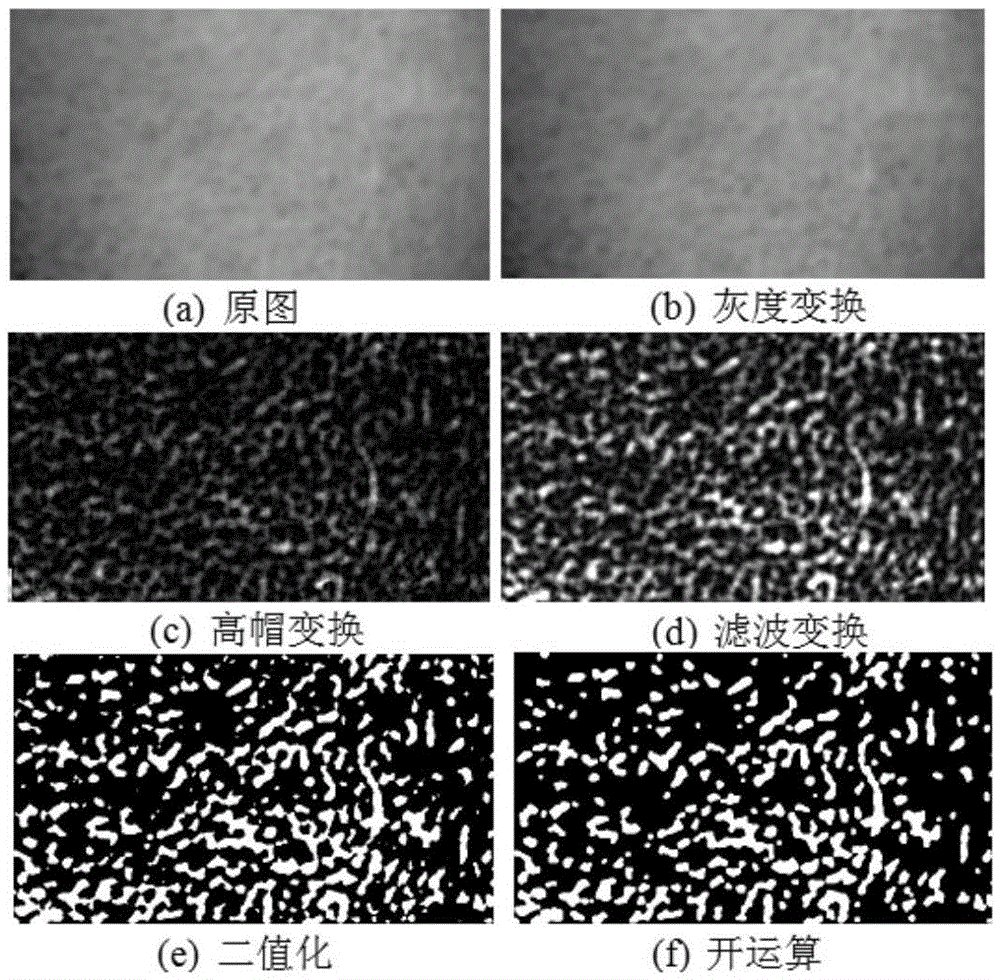

[0033] (2) Acquisition of behavior pattern of droplet group

[0034] During the test, it was observed through the visual window that the heat transfer process of the dispersed phase droplet group in the continuous phase heat transfer oil pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com