Electric air flow control device for internal combustion engines

一种空气流量、控制装置的技术,应用在机电装置、发动机控制、阀装置等方向,达到高压缩变形率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

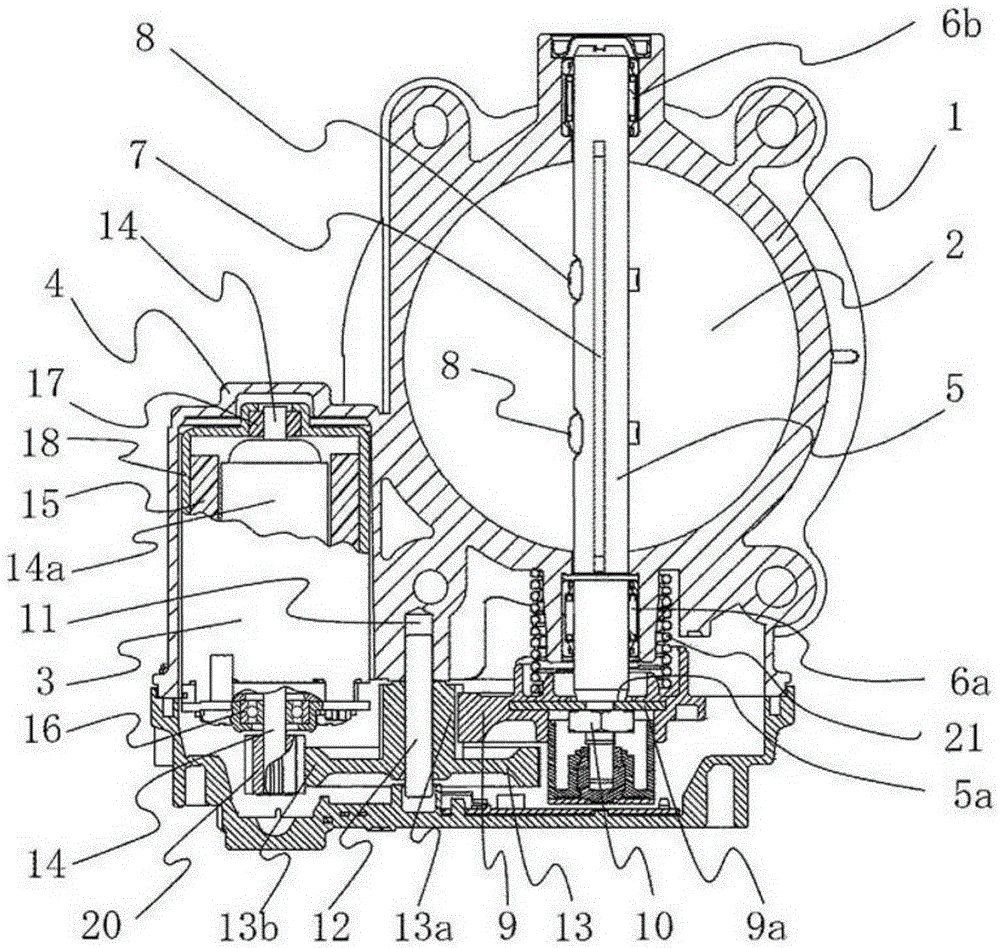

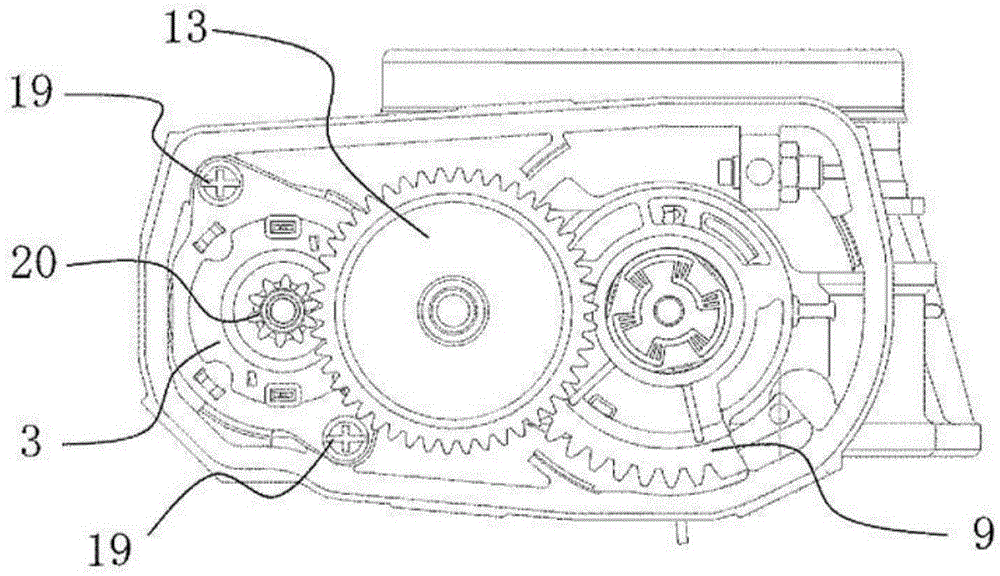

[0041] figure 1 It is an overall sectional view showing an embodiment of the inventive electric air flow control device, figure 2 is an exploded side view from the side of the various drive gears.

[0042] Generally, in the main body 1, which is mostly made of die-cast aluminum, the air intake passage 2 and the motor housing portion 4 for housing the motor 3 are integrally formed.

[0043] In the air intake passage 2 of the main body 1, the throttle valve shaft 5 passing through the passage is supported by bearing structures 6a, 6b that stably maintain the rotational movement of the throttle valve shaft 5 (in this embodiment, a needle roller structure is shown). Rolling bearings, but it can also be a rolling bearing with a ball structure, a simple cylindrical sliding bearing.) arrangement. In addition, a throttle valve 7 for optimally controlling the amount of intake air to the internal combustion engine is integrally connected by a screw 8 at a portion corresponding to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com