Cu-Sn mixture powder and process for producing the same

A technology of mixed powder and manufacturing method, which is applied in the field of bronze-based sintered powder, can solve the problems of high manufacturing cost, achieve the effect of improving sintering characteristics and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Mix the electrolytic copper powder (-100 mesh) with the atomized tin powder in a weight ratio of 89:11. 2 +N 2 In a mixed gas atmosphere, sintering (Cu-11% Sn product) is performed at 630°C. The maximum temperature residence time is 30 minutes.

[0039] As a result, a partially alloyed (70% alloyed) sintered body was obtained. After coarsely pulverizing the agglomerate, it was pulverized with a hammer mill type pulverizer (pulverizer) and sieved with a 100 mesh to obtain a Cu-11% Sn pulverized powder of -100 mesh.

[0040] Then, to the -100 mesh Cu-11% Sn pulverized powder, the -100 mesh electrolytic copper powder was added at a ratio (weight ratio) of 81.8:18.2 and placed in a mixer to obtain a Cu-9% Sn mixed powder. In addition, 0.5% (not included in the total) lubricant Metafluo A was added to the mixed powder and mixed.

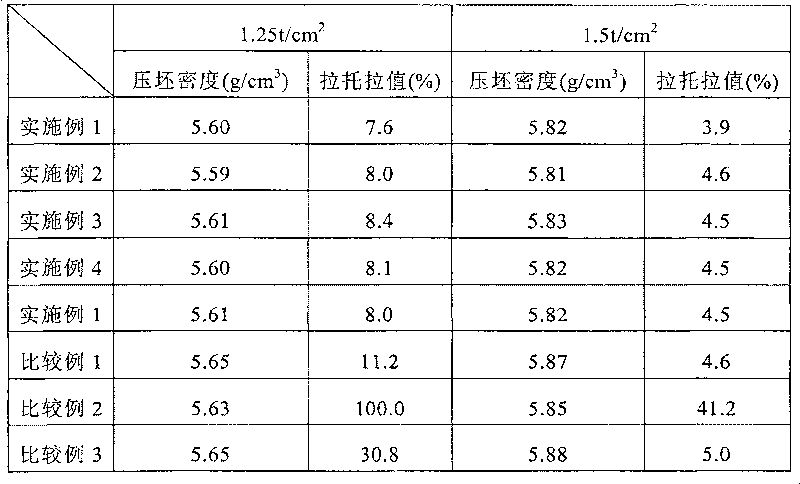

[0041] The characteristics of the mixed powder for sintering thus obtained were examined. The apparent density (g / cm 3 ) And fluidity (s / 50g), the com...

Embodiment 2

[0050] To the Cu-11%Sn pulverized powder with -100 mesh obtained in the above example 1, the electrolytic copper powder with -250 mesh was added at a ratio (weight ratio) of 81.8:18.2 and placed in a mixer to obtain Cu-9%Sn Mix the powder. In addition, 0.5% (not included in the total) lubricant Metafluo A was added to the mixed powder and mixed.

[0051] The characteristics of the mixed powder for sintering thus obtained were examined. The apparent density (g / cm 3 ) And fluidity (s / 50g), the compact density (g / cm 3 ) And Latola value (%), the radial compressive strength (kgf / mm 2 ). The results are shown in Table 1 to Table 3.

Embodiment 3

[0053] Mix the electrolytic copper powder (-100 mesh) with the atomized tin powder in a weight ratio of 89:11. 2 +N 2 In a mixed gas atmosphere, sintering (Cu-11% Sn product) is performed at 550°C. The maximum temperature residence time is 30 minutes.

[0054] As a result, a partially alloyed (60% alloyed) sintered body was obtained. After coarsely pulverizing the agglomerate, it was pulverized with a hammer mill type pulverizer (pulverizer) and sieved with a 100 mesh to obtain a Cu-11% Sn pulverized powder of -100 mesh.

[0055] Then, to the -100 mesh Cu-11% Sn pulverized powder, the -100 mesh electrolytic copper powder was added at a ratio (weight ratio) of 81.8:18.2 and placed in a mixer to obtain a Cu-9% Sn mixed powder. In addition, 0.5% (not included in the total) lubricant Metafluo A was added to the mixed powder and mixed.

[0056] The characteristics of the mixed powder for sintering thus obtained were examined. The apparent density (g / cm 3 ) And fluidity (s / 50g), the com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com