Processing technique of freeze-dried instant porridge

A processing technology and a technology for instant porridge, which is applied in the processing technology field of freeze-dried instant porridge, can solve the problems of hard taste, poor rehydration, poor chewing feeling, etc., and achieve the effects of moderate taste, keeping rice grains, and good chewing feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

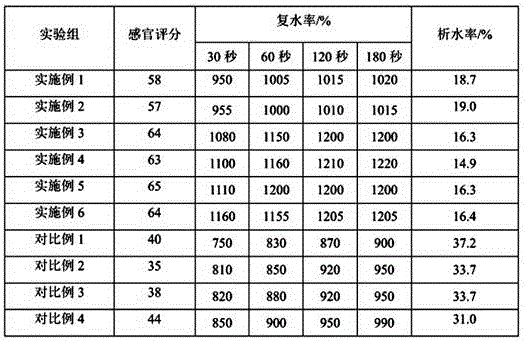

Examples

Embodiment 1

[0022] (1) Cleaning: put japonica rice (pearl rice) into drinking water twice its volume, stir and wash for 1 min; repeat the washing;

[0023] (2) Drain: Pour the cleaned japonica rice with a thickness of no more than 10cm on a stainless steel screen to drain for 3 minutes, mix well, and put it in a frame. The thickness is controlled at 18-20cm;

[0024] (3) Freezing: place the framed japonica rice in a -15°C freezer and freeze for 6 hours;

[0025] (4) Cooking: Weigh the frozen japonica rice and water according to the mass ratio of 1:11, mix them evenly, start cooking, count the time after the water boils, and cook for 30 minutes to get a semi-finished product;

[0026] (5) Packing: evenly pour the cooked semi-finished product into the mold;

[0027] (6) Cooling: Cool the semi-finished product at room temperature to room temperature after loading;

[0028] (7) Vacuum freeze-drying: Send the frozen semi-finished product into a freeze-drying furnace. The freeze-drying parame...

Embodiment 2

[0030] (1) Cleaning: Put japonica rice (pearl rice) into drinking water 2.5 times its volume, stir and wash for 1 min; repeat the washing once;

[0031] (2) Drain: Pour the cleaned japonica rice with a thickness of no more than 10cm on a stainless steel screen to drain for 3 minutes, mix well, and put it in a frame. The thickness is controlled at 20-21cm;

[0032] (3) Freezing: place the framed japonica rice in a freezer at -18°C for 8 hours;

[0033] (4) Cooking: Weigh the frozen japonica rice and water according to the mass ratio of 1:11, mix them evenly, start cooking, count the time after the water boils, and cook for 30 minutes to get a semi-finished product;

[0034] (5) Packing: evenly pour the cooked semi-finished product into the mold;

[0035] (6) Cooling: Cool the semi-finished product at room temperature to room temperature after loading;

[0036] (7) Vacuum freeze-drying: Send the frozen semi-finished product into a freeze-drying furnace. The freeze-drying param...

Embodiment 3

[0038] (1) Cleaning: put japonica rice (pearl rice) into drinking water twice its volume, stir and wash for 1 min; repeat the washing;

[0039] (2) Drain: Pour the cleaned japonica rice with a thickness of no more than 10cm on a stainless steel screen to drain for 3 minutes, mix well, and put it in a frame. The thickness is controlled at 18-20cm;

[0040](3) Freezing: place the framed japonica rice in a -15°C freezer and freeze for 6 hours;

[0041] (4) Cooking: Weigh the frozen japonica rice and water according to the mass ratio of 1:11, mix them evenly, and add 0.03% vitamin E of the total mass of the frozen japonica rice and water, start cooking, and boil with water After the timing, the cooking time is 30 minutes, and the semi-finished product is obtained;

[0042] (5) Packing: evenly pour the cooked semi-finished product into the mold;

[0043] (6) Cooling: Cool the semi-finished product at room temperature to room temperature after loading;

[0044] (7) Slow freezing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com