Fluidized and semi-fluidized microwave heating device capable of achieving Chinese cooking, stir-frying and frying industrialization

A technology of microwave heating device and microwave heating cavity, which is applied in the field of microwave heating devices, can solve the problems of harm to the body of the eater, large heat loss, loss of nutrients, etc., and achieve the effect of intense energy mass exchange, small heat loss, and prevention of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

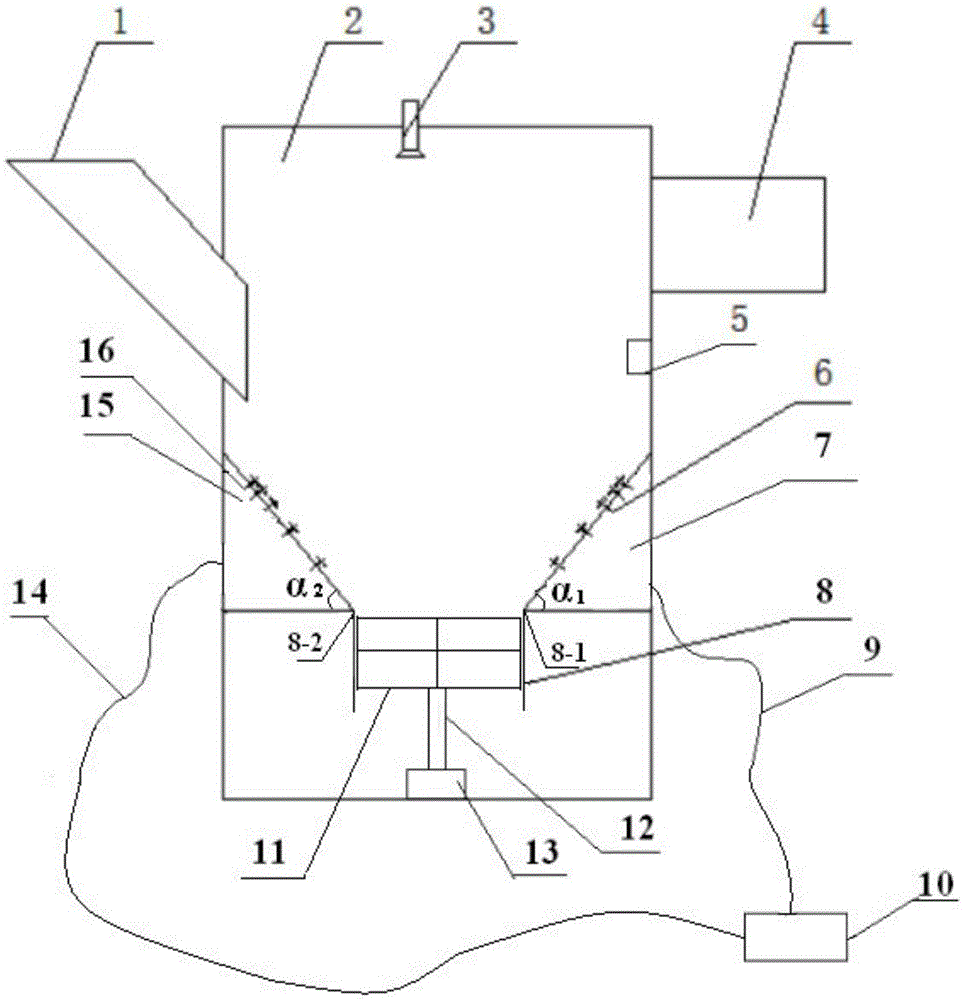

[0029] Embodiment 1: In this embodiment, a fluidized and semi-fluidized microwave heating device that can realize the industrialization of Chinese cooking, frying and frying includes: a food feeder 1, a fluidized microwave heating chamber 2, atomization of oil and liquid seasoning Device 3, microwave generator 4, air distribution nozzle one 6, air chamber one 7, duct 8, air inlet pipe one 9, blower fan 10, food vibrating device 11, transmission device 12, motor 13, air inlet pipe two 14, Air chamber two 15 and air distribution nozzle two 16;

[0030] Among them, the left outer wall of the fluidized microwave heating chamber 2 is provided with a food feeder 1, the right outer wall is provided with a microwave generator 4, the top is provided with an oil and liquid seasoning atomizer 3, the bottom is provided with a motor 13, and the food feeder 1 The feeding port is communicated with the fluidized microwave heating chamber 2;

[0031] The inner walls of both sides of the fluid...

specific Embodiment approach 2

[0041] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: the angle α between the slope of the air chamber 7 and the horizontal plane 1 It is 45-60°. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0042] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is: the angle α between the slope of the air chamber 2 15 and the horizontal plane 2 It is 45-60°. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com