Dental implant and preparation method thereof

A dental implant and body technology, applied in the field of dental implants and its preparation, can solve the problems of micro-infiltration, poor biocompatibility and poor stability of dental implants, so as to improve the ability to resist micro-dynamics and avoid micro-infiltration and infection, and the effect of improving biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

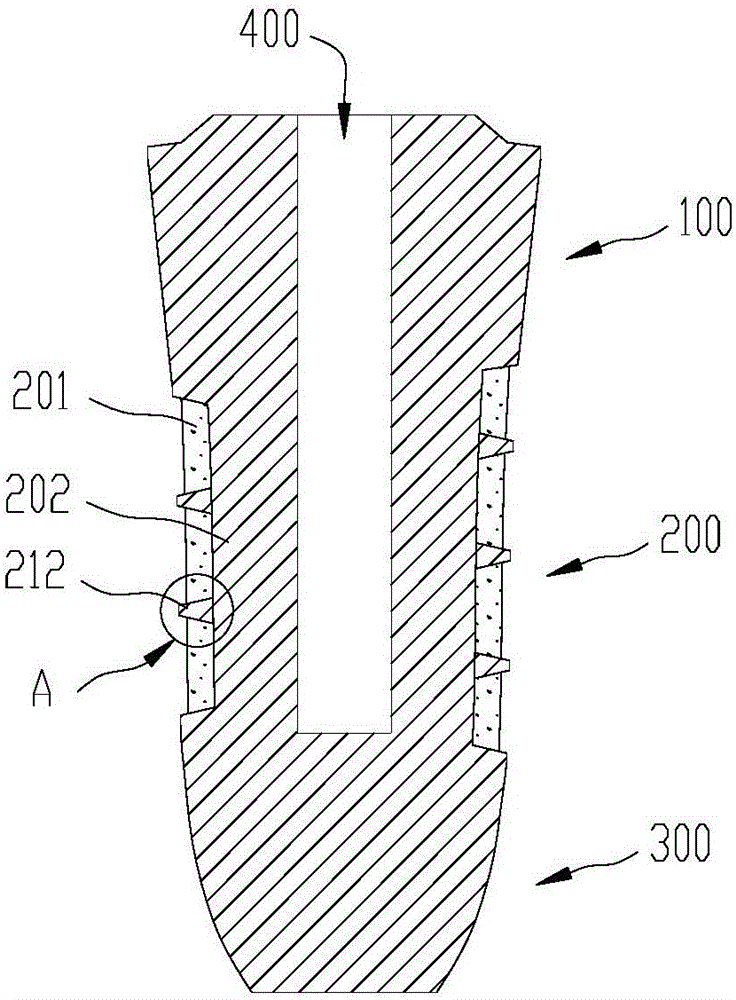

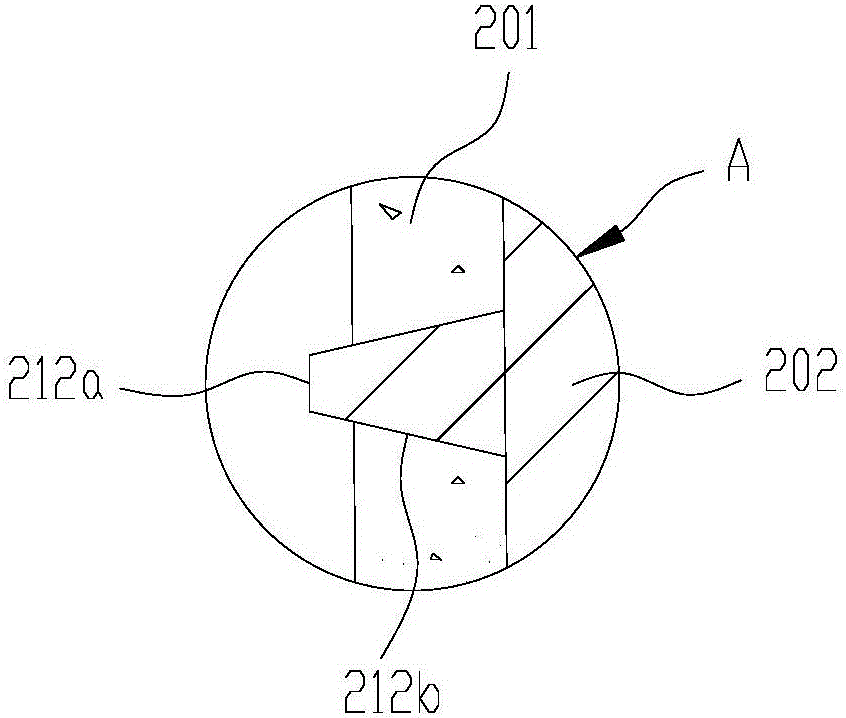

[0026] Such as figure 1 and figure 2The dental implant shown comprises a neck implant segment 100, a body implant segment 200 and a tail implant segment 300 connected in sequence, and the end face of the neck implant segment 100 is provided with a downwardly penetrating body implant segment. The central hole 400 of 200, the body implant segment 200 has a core 202 made of dense metal and an outer peripheral part 201 made of porous metal covering the outside of the core 202, the central hole 400 is located in the core 202 , the core part 202 and the peripheral part 201 are integrally formed by additive manufacturing. The neck implant segment 100 is made of dense metal. A dense metal support 212 is provided between the core 202 and the outer periphery 201 , and the dense metal support 212 , the core 202 and the outer periphery 201 are also integrally formed by additive manufacturing. The dense metal support 212 includes continuous protrusions 212a distributed in the circumfer...

Embodiment 2

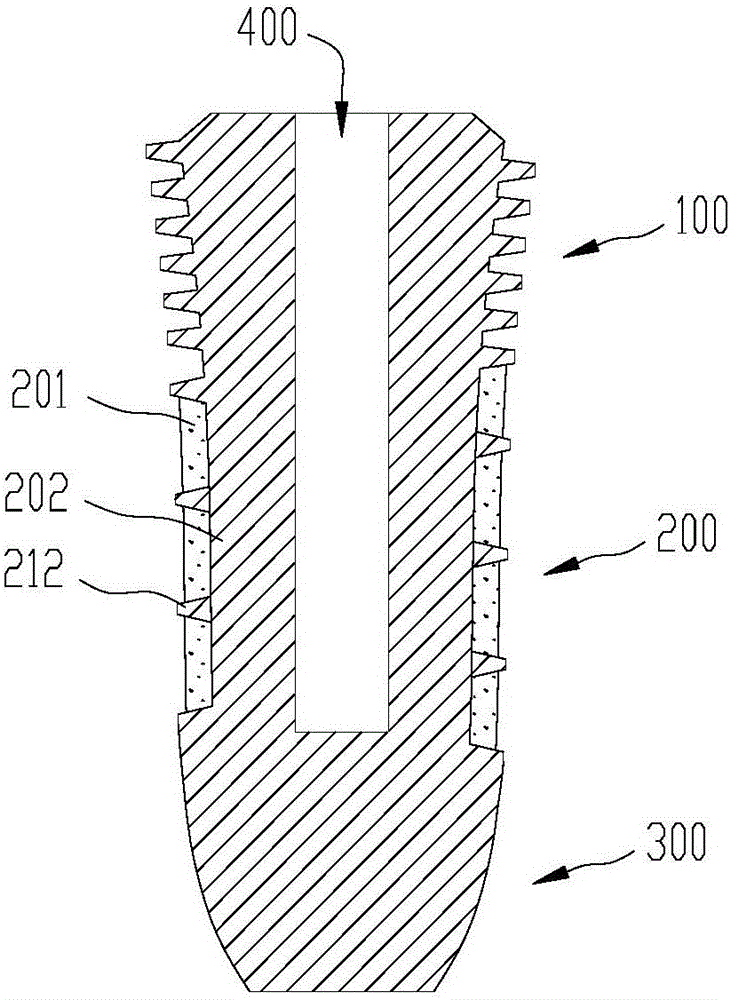

[0030] Such as image 3 For the dental implant shown, on the basis of Example 1, the neck implant segment 100 and the body implant segment 200 have external thread regions made of dense metal with different pitches, and the body implant segment The externally threaded regions of the segment 200 have a larger pitch and are staggered with the outer peripheral portion 201 . The pitch of the external thread area of the body implant segment 200 is 2 mm, and the pitch of the external thread area of the neck implant segment 100 is 0.5 mm. The externally threaded area of the body implant segment 200 is the dense metal support 212 of the core 202 . Tail implant segment 300 is constructed of dense metal.

Embodiment 3

[0032] Such as Figure 4 with Figure 5 For the dental implant shown, on the basis of Example 2, the tail implant section 300 has an external threaded area made of dense metal, and a tail is provided between the threaded alveoli of the external thread area of the tail implant section 300 porous region 301 . The tail implant section 300 is made of porous metal, and the pitch of the external thread area is 0.75 mm. The tail implant segment 300 is tapered and provided with an axial cutting edge 302 . The externally threaded area of the body implant segment 200 is the dense metal support 212 of the core 202, including a continuous protrusion 212a and a connecting portion 212b. In this way, the neck implant segment 100 , the body implant segment 200 and the tail implant segment 300 respectively have external thread regions with different pitches.

[0033] The beneficial effects of the present invention have:

[0034] 1) Good stability.

[0035] The stability of the dental...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com