Comb desulphurization mist eliminator

A demister and blade technology, which is applied in the field of comb desulfurization demisters, can solve the problems of scaling and clogging of wet desulfurization demisters, and achieve the effects of reducing slurry circulation, reducing maintenance times, and saving flushing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below by embodiment, and in conjunction with accompanying drawing, the present invention will be further described:

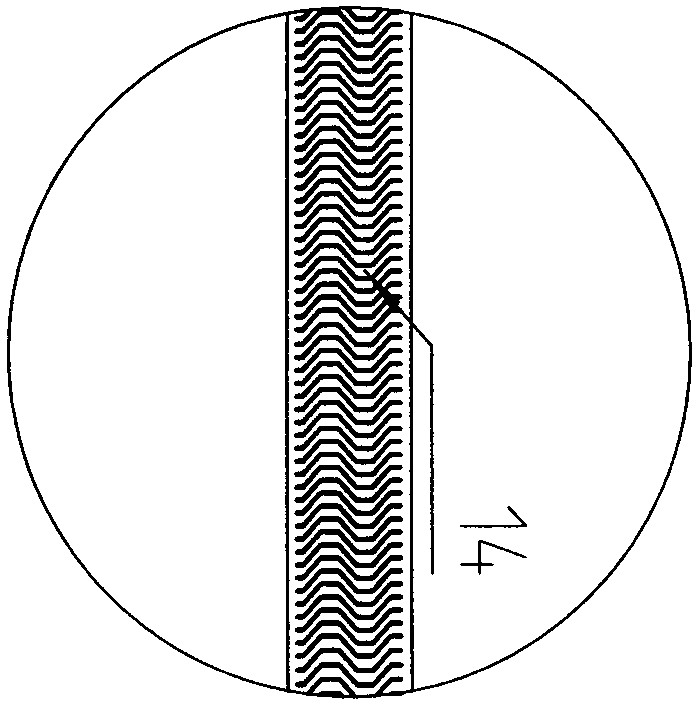

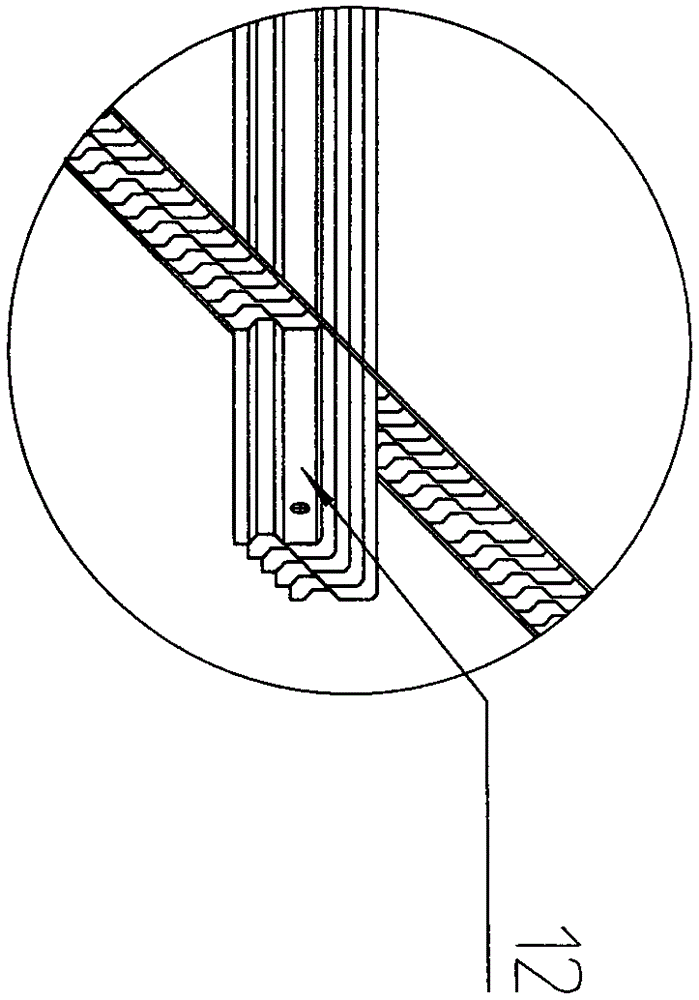

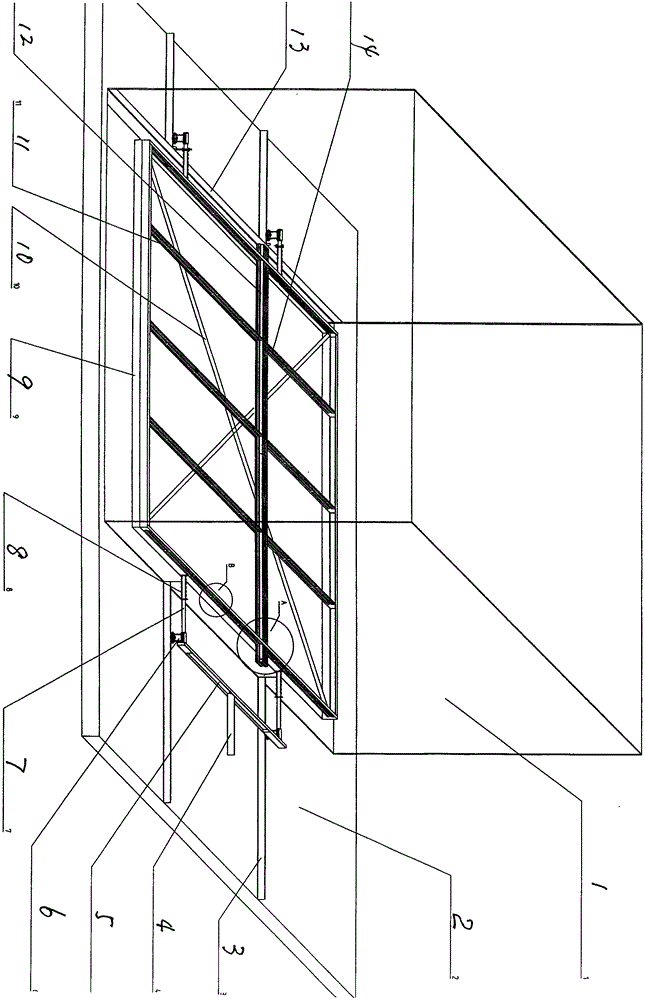

[0017] Such as figure 1 As shown, the demister consists of a horizontally movable rectangular frame 9 with reinforcing ribs 10 at the corners, four support legs 7 with track wheels 6, a rectangular frame 9 with combs 11, and fixed N blades. 12 poses.

[0018] The rectangular frame 9 is surrounded by four borders, front, rear, left, and right. The two diagonals of the rectangular frame 9 are fixedly connected with reinforcing ribs 10, and the front and rear frames are horizontally and vertically fixedly connected with rows of combs 11 parallel to each other and equally spaced. With a gap of 1 mm, the row combs 11 can be pushed (pull) by the hydraulic rod 4 along with the rectangular frame 9 to advance (or pull out) a set stroke horizontally. The N blades 12 perpendicular to the row of combs pass through all the rows of comb teeth 14 holes, and the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com