Moisture-absorbing and cold-resisting shell fabric with flame-retardant function

A fabric and functional technology, applied in synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of complex process, cold and wet feeling, slow water dispersion, etc., and achieve simple fabric structure and cold resistance. , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

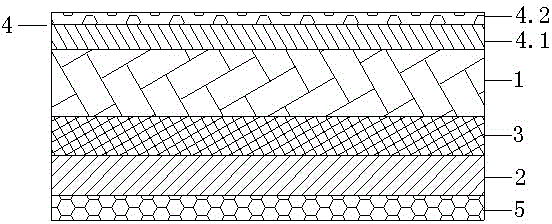

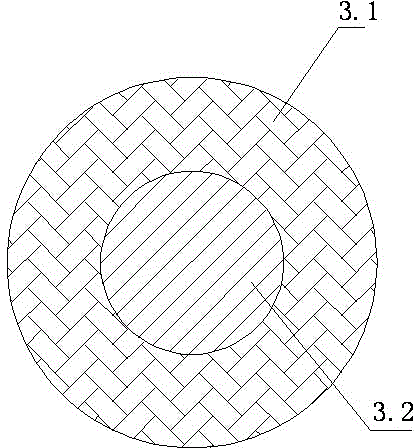

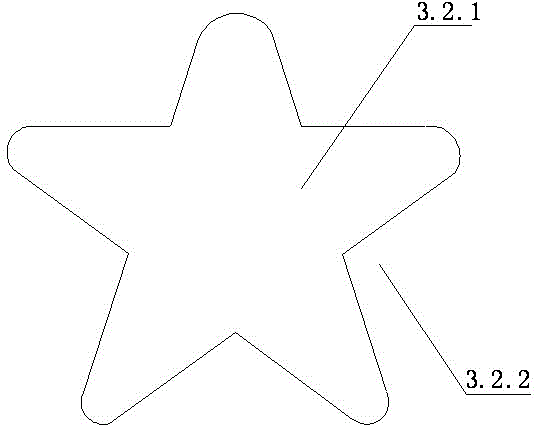

[0014] see Figure 1 to Figure 3 , the invention relates to a moisture-absorbing and cold-resistant fabric with a flame-retardant function, which comprises an upper cotton layer 1 and a lower cotton layer 2, and a base layer 5 is compounded on the upper cotton layer 1, and the upper cotton layer 1 and the lower cotton layer There is also a hygroscopic layer 3 between the 2, and the hygroscopic layer 3 is made of polyester fiber 3.1 and polyamide fiber 3.2 through blending and weaving, wherein the polyester fiber 3.1 is the skin layer, and the polyamide fiber 3.2 is the core layer. The polyamide fiber 3.2 has Hydrophilic, the polyamide fiber section 3.2.1 of the polyamide fiber 3.2 is in the shape of a five-pointed star, and a groove 3.2.2 is formed between two adjacent corners of the five-pointed star, and sweat is discharged from the groove 3.2.2 The surface of the fabric is thus volatilized, thereby achieving the purpose of moisture absorption and perspiration.

[0015] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com