Glass fiber double-layer oil tank and production device as well as preparation method

A glass fiber, double-layer oil tank technology, applied in the field of double-layer oil tanks, can solve the problems of pollution, erosion and electrolytic corrosion, oil loss environment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

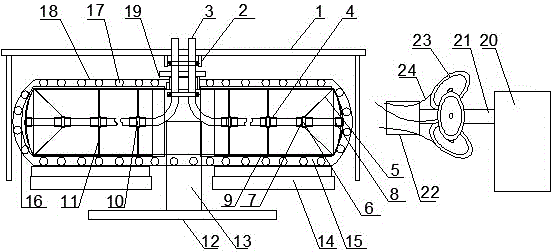

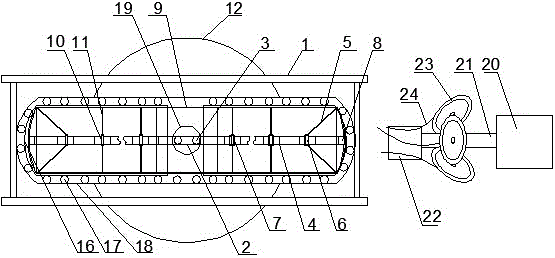

[0023] according to figure 1 , 2 As shown, the present invention relates to a glass fiber double-layer oil tank, which comprises two modified polyethylene ceramic double-layer half-tanks screwed to each other, and the outer sides of the modified polyethylene ceramic double-layer half-tank are bonded There is a storage inner tank layer 16 made of glass fiber, and the storage inner tank layer 16 made of glass fiber is a first glass fiber wide cloth tape winding layer, a first glass fiber short fiber layer and a first glass fiber short fiber layer that are arranged in parallel and bonded successively by an adhesive. , the first three-dimensional interweaving layer of glass fiber cloth, the first anti-seepage layer, the first S-twisted yarn layer, the first anti-corrosion curing layer, glass fiber twisted spun cloth layer, the first Z-twisted yarn layer, the first glass fiber Twisted roving layer and the second anti-corrosion solidified layer; the outer wall of the storage inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com