High-sensitivity wide-range force sensor and manufacturing method thereof

A force sensor and high-sensitivity technology, applied in the field of high-sensitivity and wide-range piezoresistive force sensor and its manufacturing field, can solve the problem that the measurement range and accuracy cannot be well balanced, and achieve sensitivity and range optimization, high sensitivity, and guarantee reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

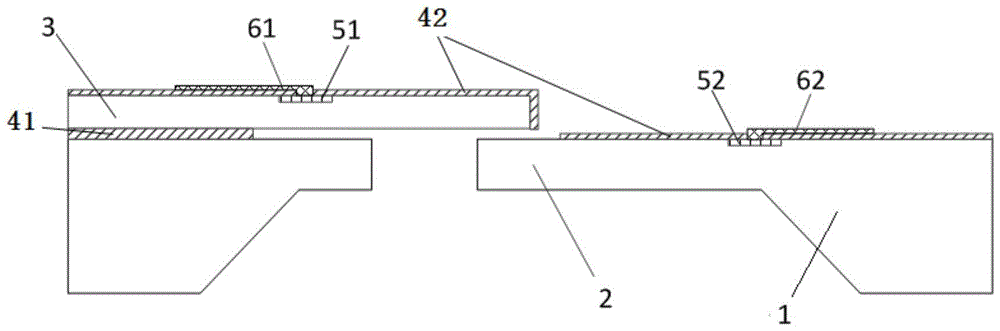

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] The invention proposes a piezoresistive force sensor structure with higher sensitivity and wider range. The sensor is made of SOI silicon wafer, and the upper silicon film of the SOI silicon wafer is used to fabricate a force-sensitive structure with higher sensitivity but narrower range; the bulk silicon is used to fabricate a force-sensitive structure with wider range but lower sensitivity, combined with the above Two sensor structures with different sensitivities and measuring ranges obtain a force sensor with both higher sensitivity and wider measuring range. When the external force measured by the sensor is small, the upper high-sensitivity structure bends downward, and the lower-layer wide-range sensitive structure remains unchanged. At this time, the output of the sensor is determined by the upper-layer high-sensitivity structure; when the measured force ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com