Production method of thermal transfer printing base paper

A thermal transfer printing and production method technology, applied in the direction of paper, papermaking, special paper, etc., can solve the problems of fabric scrapping and fabric not meeting the requirements, so as to improve product quality, improve washing process, and reduce the formation of hidden white spots Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

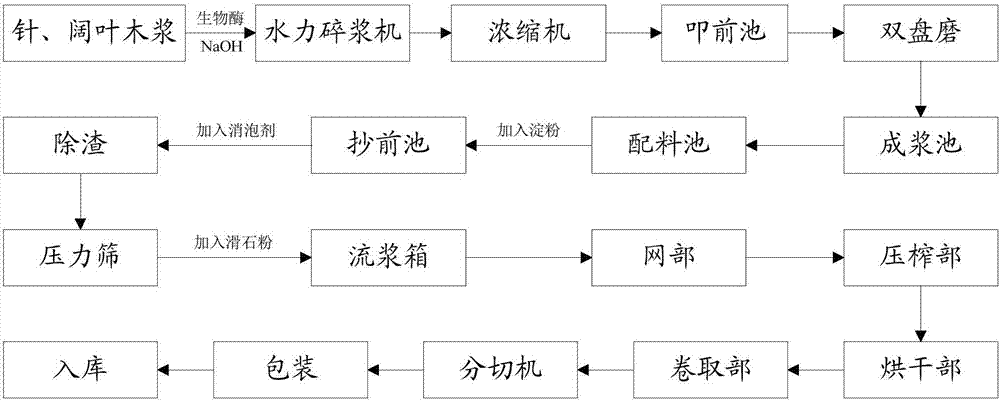

Method used

Image

Examples

Embodiment Construction

[0009] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

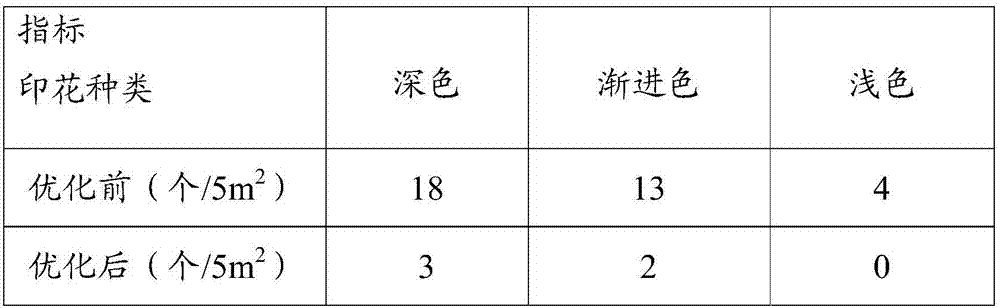

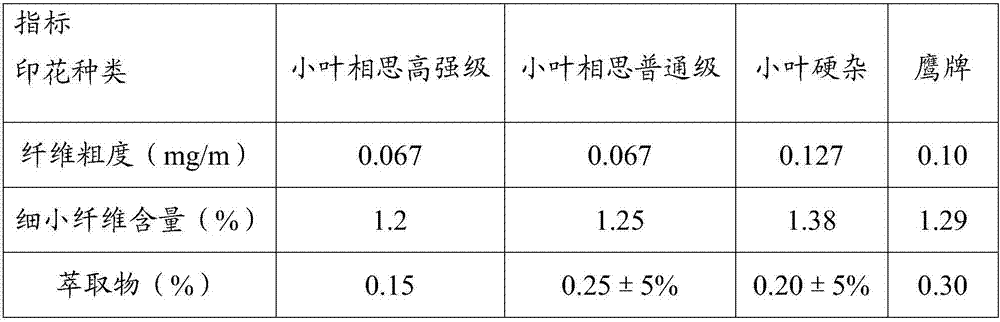

[0010] Since the main raw material of high-grade printing base paper is imported commercial wood pulp, through customer feedback and production practice in recent years, it is found that one of the main factors causing hidden white spots on paper is the degree of washing of the pulp board and the impact of pulp properties. Due to the insufficient cleaning degree of commercial wood pulp in the process of delignification and bleaching reduction, there will be more residual oxidants or reducing agents in the pulp, which are powdery and unresolved fine particles. , papermaking and other processes, but in the end there are still a small amount of particles that cannot be effectively dissociated will adhere to the fibers and be brought into the paper. Some of these par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com