A high-efficiency recycling production process of occ slurry

A production process and recycling technology, applied in the direction of textiles and papermaking, papermaking, paper machine wet end, etc., to achieve significant economic and environmental benefits, improve the yield of good pulp, and increase the output of slag pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe in detail the technical content of the technical solution and the achieved objectives and effects, the following will be described in detail in combination with specific embodiments and accompanying drawings.

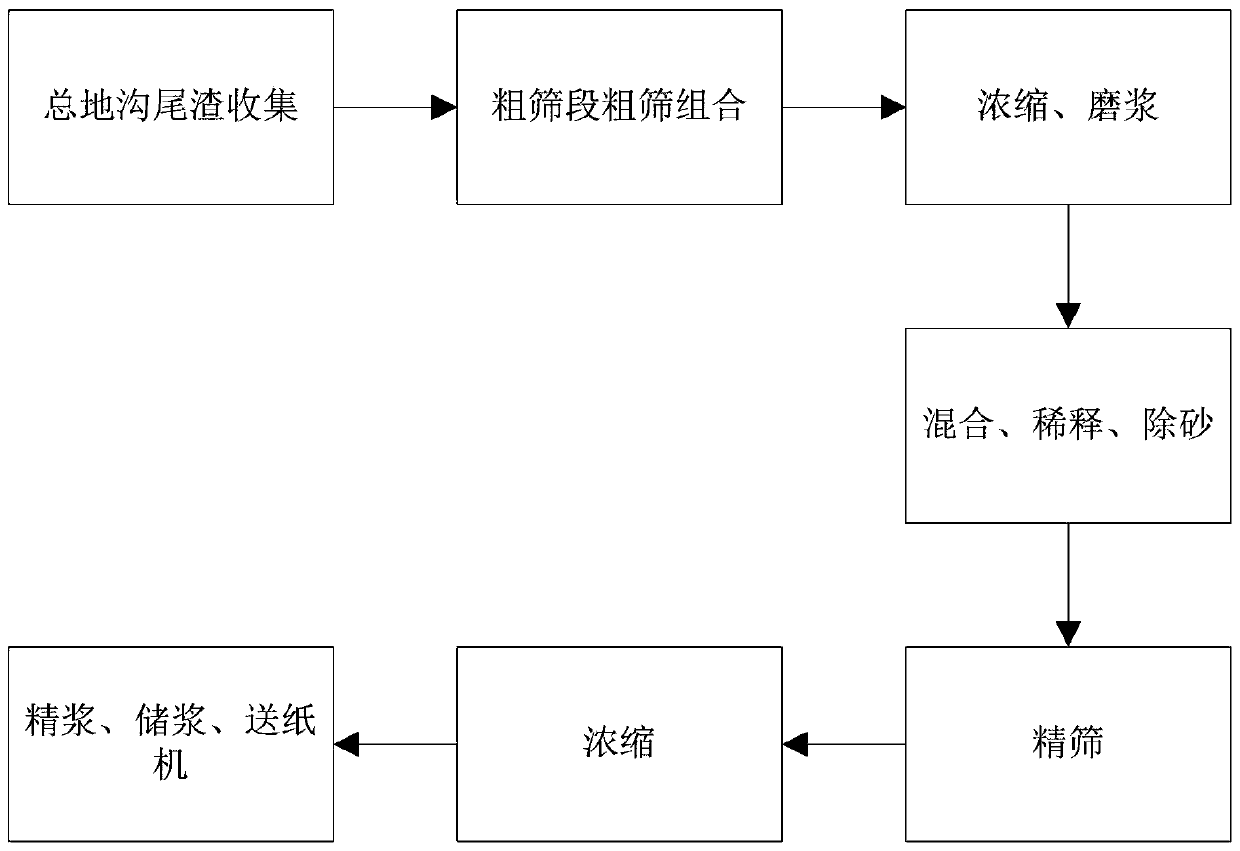

[0028] see figure 1 , this embodiment provides a high-efficiency recycling production process for OCC slurry.

[0029] Taking a paper mill with a production capacity of 2.2 million tons per year as an example, the absolute dry volume of total slag discharge, fine screen tailings, and low-concentration slag remover tailings in the whole plant is about 500 tons per day.

[0030] Total trench tailings collection: The total trench white water is recycled through the inclined screen of the sewage treatment plant to obtain the trench recovery slurry. The trench recovery slurry is transported to the sewage slurry collection tank after thickening, and then sent to the coarse screening section to remove large impurities and plastic sheets to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com