Heat insulation removable house

A prefab house, thermal insulation technology, applied in the direction of roofing, roofing, and residential buildings using flat/curved panels, can solve the problems of insufficient thermal insulation performance, poor thermal insulation, poor thermal insulation effect, unsuitable for living, etc. Good thermal insulation effect, good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

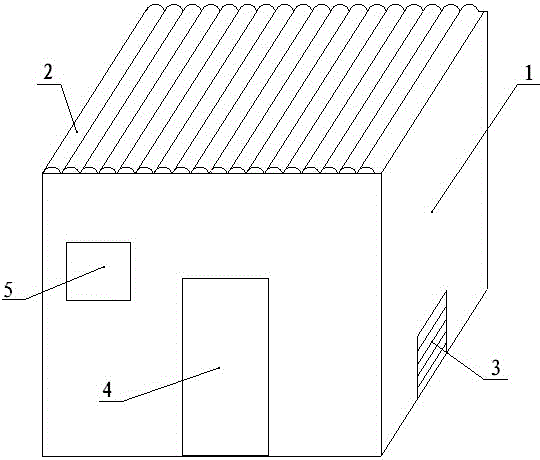

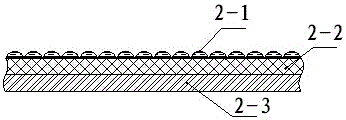

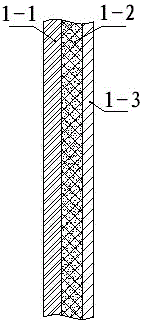

[0012] Such as figure 1 , figure 2 and image 3 The illustrated embodiment comprises wall panels 1 and a roof 2 constructed of steel materials, wherein one wall panel is provided with a louver exhaust bottom window 3 for ventilation, and the other wall is provided with a door 4 and a louver for light transmission. Window 5, the roof consists of an outer layer, an intermediate layer and a bottom layer. The outer layer is a corrugated asbestos tile layer 2-1, the middle layer is a foam layer 2-2, and the bottom layer is a steel plate layer 2-3. The foam layer has a good Heat insulation effect; wall panel 1 is composed of outer layer, middle layer and inner layer, the outer layer is protective layer 1-1, the middle layer is thermal insulation layer 1-2, the inner layer is decorative layer 1-3; thermal insulation layer 1- 2. It is made of filled glass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com