Full-automatic intelligent hydraulic workover rig

A fully automatic, workover rig technology, applied in drilling equipment, drilling equipment and methods, and earthwork drilling, etc., can solve the problems of harsh working environment, high risk factor, waste of electric energy, etc., and achieve the effect of reasonable distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

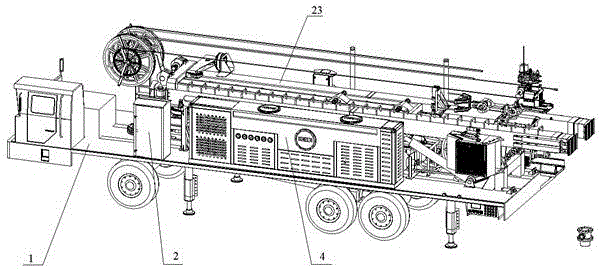

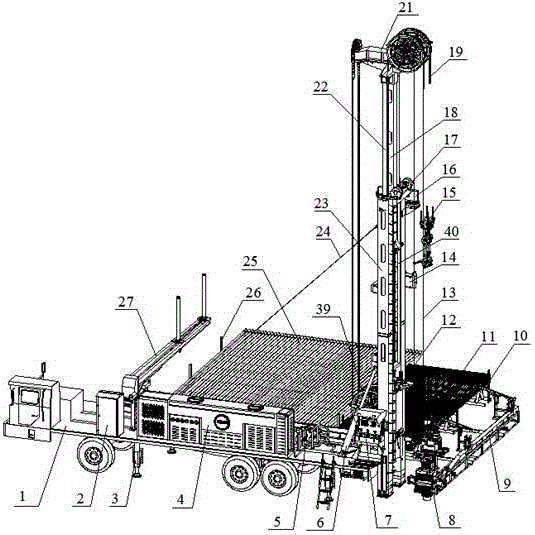

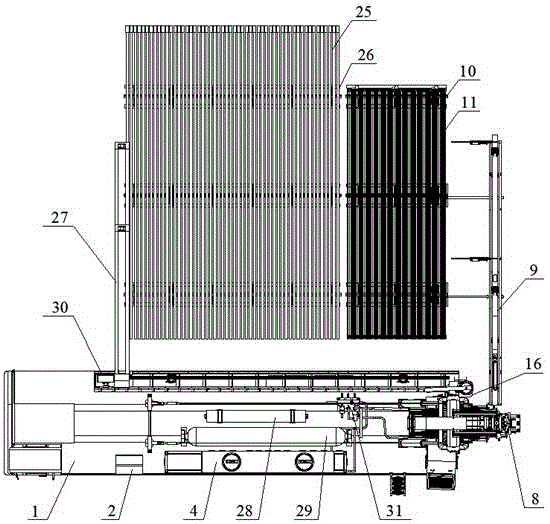

[0043] Such as Figure 1-20 As shown, a fully automatic intelligent hydraulic workover rig includes vehicle-mounted chassis 1, electric control cabinet 2, chassis outrigger 3, hydraulic station 4, energy storage compensation device 5, luffing cylinder 6, console 7, and automatic wellhead device 8. Automatic pipe arrangement mechanism 9, sucker rod pipe arrangement assembly 10, sucker rod 11, righting manipulator 12, flexible guide rail wire rope 13, small crane winch 14, hydraulic elevator 15, small crane 16, flexible guide rail winch 17 , master cylinder slide guide block 18, main wire rope 19, main wire rope fixed end 20, top driving device 21, main hydraulic cylinder 22, derrick 23, cable-stayed wire rope 24, oil pipe 25, oil pipe arrangement assembly 26, transfer pipe Mechanism assembly 27, accumulator 28, nitrogen bag 29, pipette guide rail 30, main valve block 31, pipette rack 32, pipette roller 33, pipette trolley 34, rotating mechanism assembly 35, pipette cantilever a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com