Absolute grating scale and measuring method based on CMOS image sensor

A technology of image sensor and grating ruler, applied in measurement devices, instruments, optical devices, etc., can solve the problems of limited coding range, increased production cost, output signal error, etc., to improve measurement resolution, reduce etching difficulty, The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

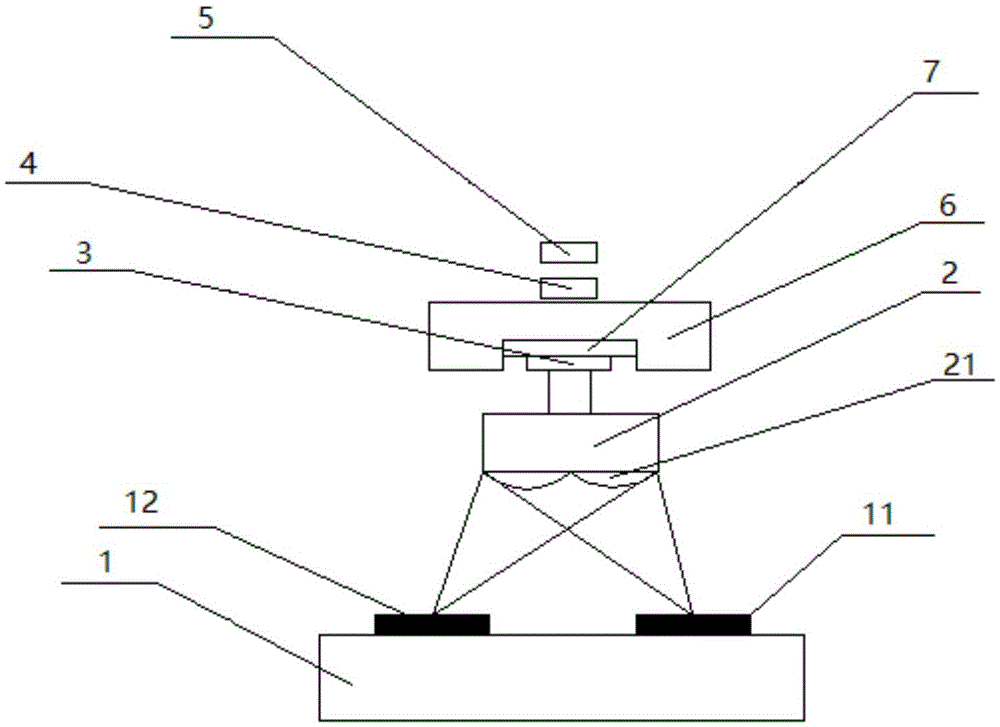

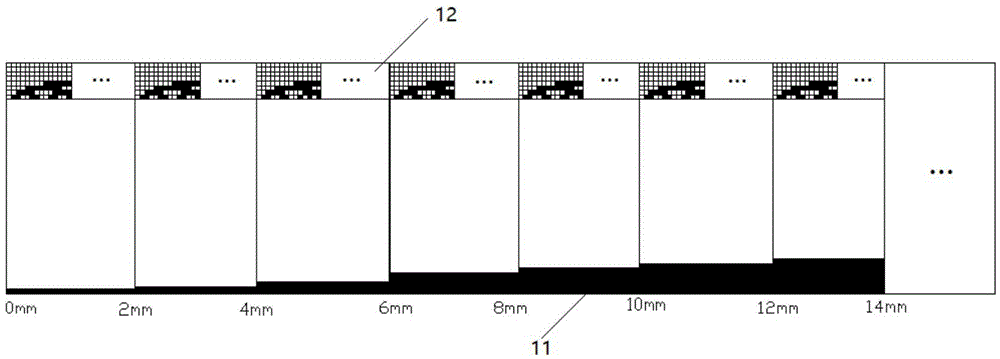

[0049] Reference figure 1 , Absolute grating ruler based on CMOS image sensor, including grating ruler body 1, optical magnification system 2, CMOS image sensor 3, signal processing module 4, main control module 5 and correction compensation for motion compensation of CMOS image sensor 3 Unit 6, the grating ruler body 1 is provided with a measurement code channel 11 and a subdivision code channel 12. The optical magnification system 2 is used to collect the light reflected or transmitted by the measurement code channel 11 and the subdivision code channel 12 and converge and enter the CMOS image On the sensor 3, the CMOS image sensor 3 is used to collect the arriving light signal to obtain an analog image of the current measurement position and send it to the signal processing module 4. The signal processing module 4 is used to convert the analog image into a digital image and send it to the main control module 5. The main control module 5 is used to process the digital image to ...

Embodiment 2

[0054] The measuring method of the absolute grating ruler based on the CMOS image sensor in the first embodiment includes the steps:

[0055] S1. Install the grating ruler body 1 on the object to be measured and drive the object to be measured to move;

[0056] S2, the optical amplification system 2 collects the light reflected or transmitted by the measurement code channel 11 and the subdivided code channel 12, and converges and enters the CMOS image sensor 3;

[0057] S3. The CMOS image sensor 3 obtains the analog image of the current measurement position after collecting the arrived light signal and sends it to the signal processing module 4;

[0058] S4. The signal processing module 4 converts the analog image into a digital image and sends it to the main control module 5;

[0059] S5. The main control module 5 processes the digital image to obtain the coarse position value and the subdivision position value respectively, and then combine to obtain the absolute position measurement ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com