Method for predicting TC6 titanium alloy forging piece microstructural parameters

A technology of microstructure and prediction method, applied in geometric CAD, electrical digital data processing, special data processing applications, etc., can solve problems such as poor practicability, and achieve high accuracy and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1: Prediction of primary α-phase grain size of TC6 titanium alloy forgings.

[0035] (1) Machining the supplied TC6 titanium alloy bar with a diameter of 35mm to obtain a thermal simulation compression sample with a diameter of 8mm and a height of 12mm;

[0036] (2) Clean the TC6 titanium alloy sample with absolute ethanol, and coat the cleaned surface with glass lubricant;

[0037] (3) Select forging deformation temperature 1073K, 1103K, 1133K, 1163K, 1193K, 1223K, 1253K, 1283K, 1313K, strain rate 0.001, 0.01, 1, 10, 50s -1 , The maximum strain is 0.69; the TC6 titanium alloy is placed in the center of the Thermocmaster-Z thermal simulation compression testing machine workbench, and the compression deformation experiment is performed on the TC6 titanium alloy after the temperature is kept for 5 minutes. After the compression deformation experiment, it is quickly cooled to room temperature by blowing nitrogen;

[0038] (4) Take half of the sample along the axis after the...

Embodiment 2

[0072] Example 2: Prediction of the volume fraction of primary α phase of TC6 titanium alloy forgings.

[0073] The difference between the implementation steps of Example 1 is that the volume fraction is measured in step (4), and the volume fraction (f α ,%) is the output value of the function;

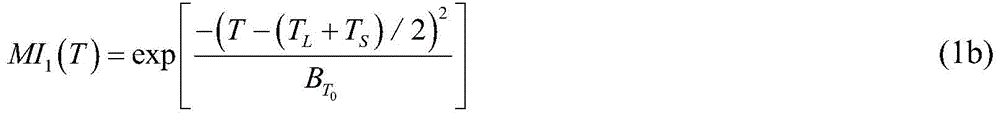

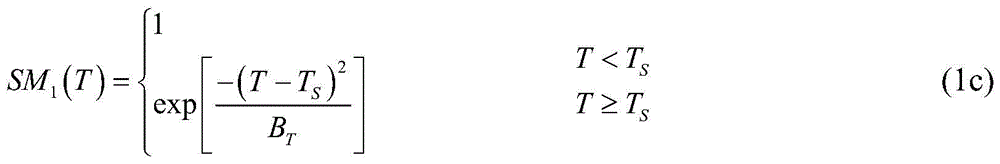

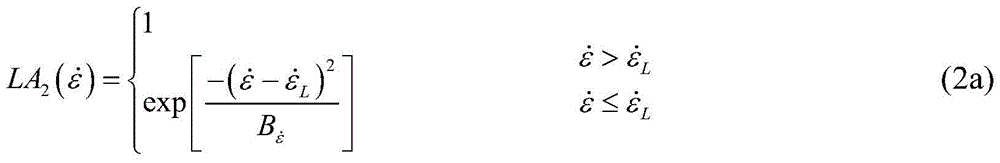

[0074] The prediction model for the volume fraction of primary α phase of TC6 titanium alloy forgings is,

[0075]

[0076] A sample of teachers who selected the volume fraction of the primary α phase of TC6 titanium alloy is shown in Table 3. Use teacher samples to train the volume fraction prediction model formula (14). When the cumulative error of the volume fraction is less than 2%, the fuzzy rule weight coefficient is optimized And fuzzy rule weight (w i ).

[0077] Substituting the determined weight coefficient and weight value of the fuzzy rule into equation (14), it is the prediction model of the volume fraction of primary α phase of TC6 titanium alloy forging. The predicted value o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com