Sizing agents for external coatings of positive and negative electrode coils of lithium ion batteries

A lithium-ion battery, positive and negative electrode technology, applied in the direction of battery electrodes, secondary batteries, active material electrodes, etc., can solve the problems of large diaphragm consumption, low battery energy density, short cycle life, etc., to avoid lithium dendrites , long cycle life, and the effect of improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below according to specific embodiments.

[0022] The slurry used for coating on the positive and negative coils of lithium-ion batteries, due to the difference in polarity, the slurry needs to be prepared separately. The surface coating is made of hard carbon. This embodiment is equipped with a 10Ah lithium-ion battery, and the layer density of the activated carbon after curing is required to be 2-20 mg / cm 2 , the solidified hard carbon layer density is 2~16mg / cm 2 . Now according to the supporting requirements, the corresponding components of activated carbon and hard carbon slurries are prepared respectively. The specific components are measured by mass percentage as follows:

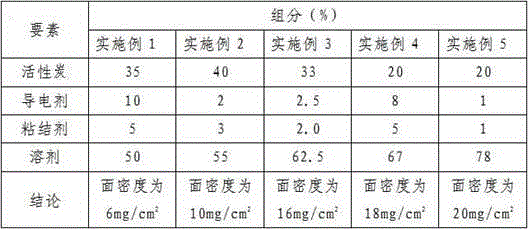

[0023] Activated carbon slurry example component table

[0024]

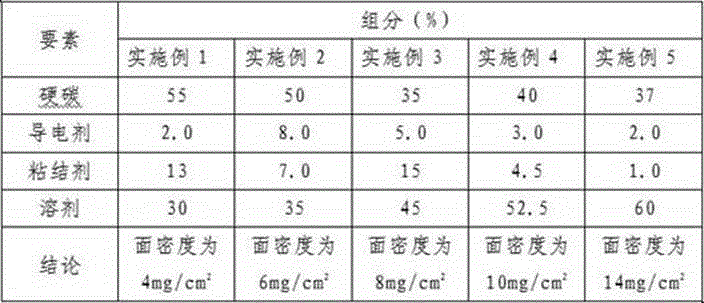

[0025] Hard carbon slurry embodiment component table

[0026]

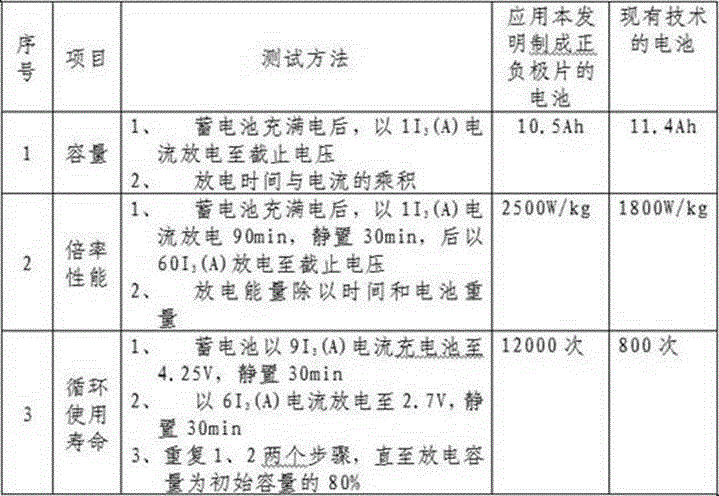

[0027] The slurries prepared in the above-mentioned embodiments were respectively coated on the surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com