Method for Fixing Amorphous Alloy Stator Core and Motor Frame or Cooling Water Jacket

A stator core and amorphous alloy technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of decreased magnetic performance of the iron core, increased iron loss, etc., and achieve the effect of avoiding eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

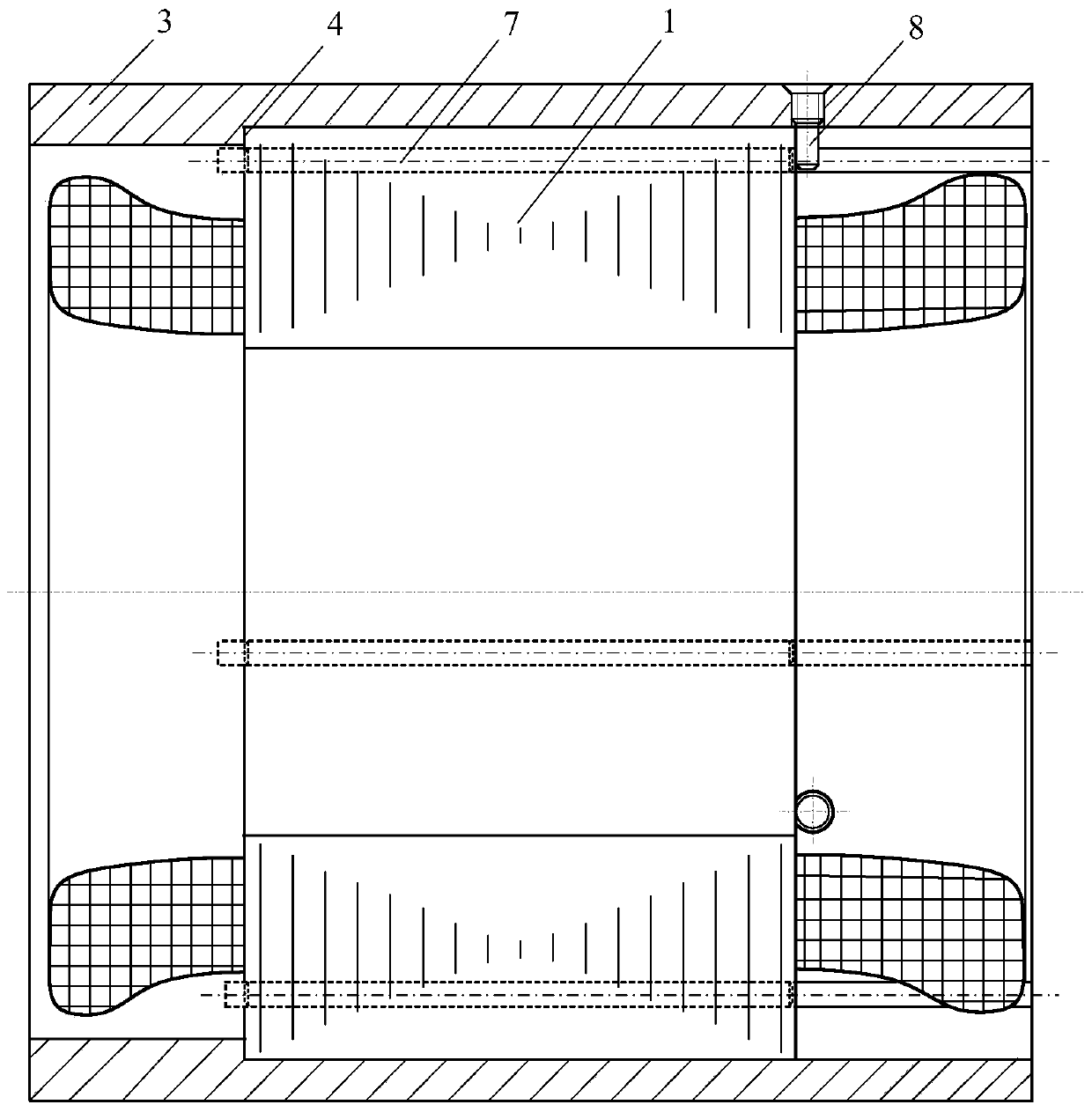

[0039] Cut the amorphous alloy strip Fe83.5B15Cu1.5 into a sheet with a length of 250mm and a width of 140mm, and cut a certain number of 0.2mm thick silicon steel sheets with the same length and width as the amorphous alloy sheet; The alloy flakes and silicon steel sheets are coated with silicate high-temperature glue with a temperature resistance of 500 degrees Celsius on both sides. The coating thickness of the high-temperature glue is less than 1 micron. The concentration of the high-temperature glue is adjusted by adding an absolute alcohol with a concentration of more than 98% to control the coating thickness. The silicon steel sheet is coated on one side only. Next, a plurality of amorphous alloy flakes are stacked into an amorphous alloy cubic block with a thickness of 75 mm in the axial direction. During the lamination process, put four double-sided glued 0.2mm thick silicon steel sheets at each end of the axial direction, and place a single-sided glued silicon steel s...

Embodiment 2

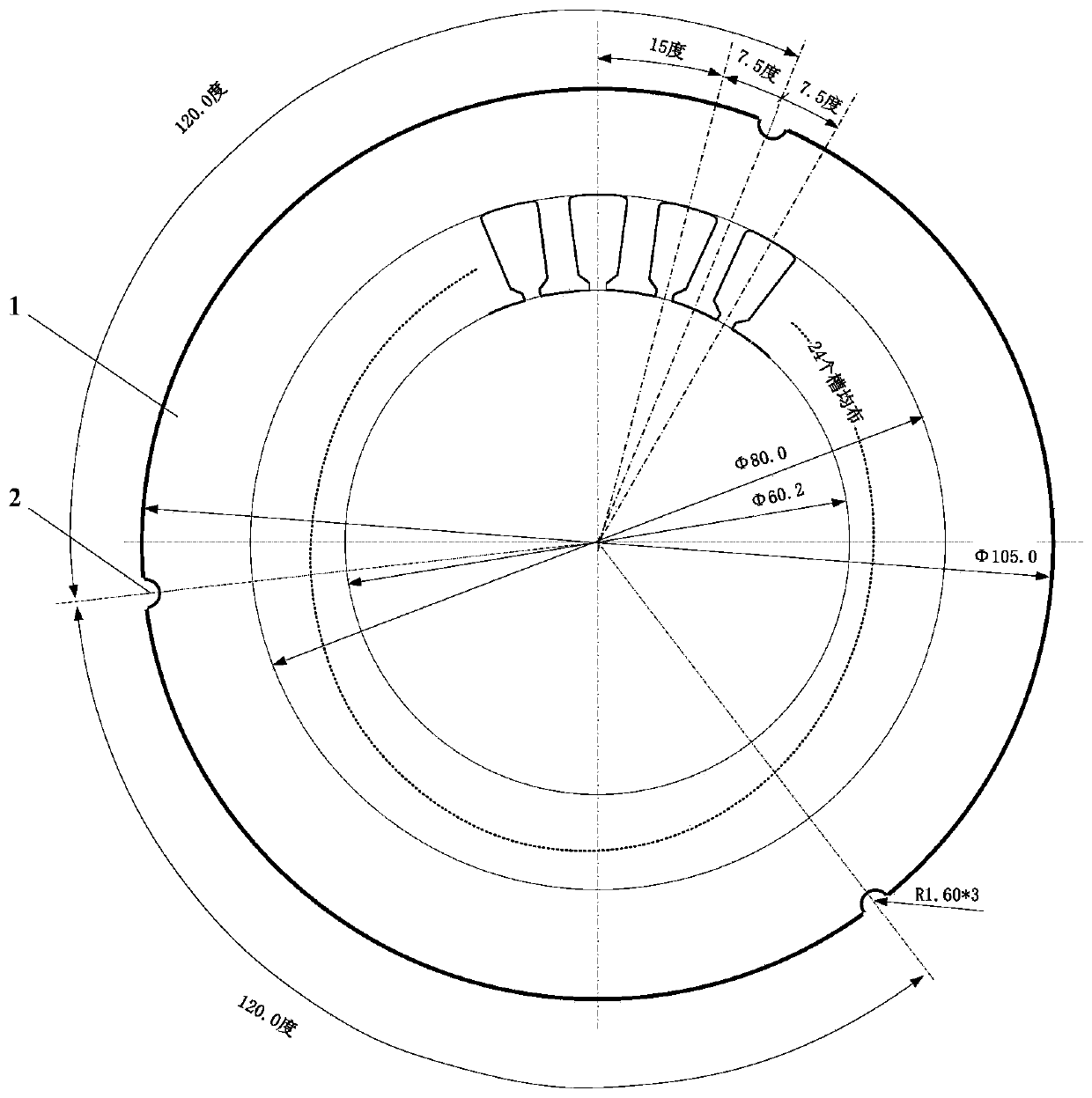

[0052] Mix bisphenol S epoxy resin and diluent benzyl alcohol thoroughly. The volume ratio of epoxy resin and benzyl alcohol is 1:2. Then add curing agent diethylenetriamine-acrylonitrile copolymer. The diluted ring The ratio of oxygen resin to curing agent is 15:1. Then the amorphous alloy Fe 85 B 11 Si 4.0 The powder is thoroughly mixed with the diluted epoxy resin, and the ratio of the amorphous alloy powder to the diluted epoxy resin after adding the curing agent is 100:30. Then, the mixture of the fully mixed amorphous alloy powder and epoxy resin is put into the stator core mold under pressure of 80-100 MPa, and heated to 80 degrees Celsius for curing for 12 hours. The axial length of the molded amorphous silicon alloy stator core 9 is 180 mm, the inner diameter is 160.0 mm, the outer diameter is 260 mm, and 24 cogging slots are evenly distributed.

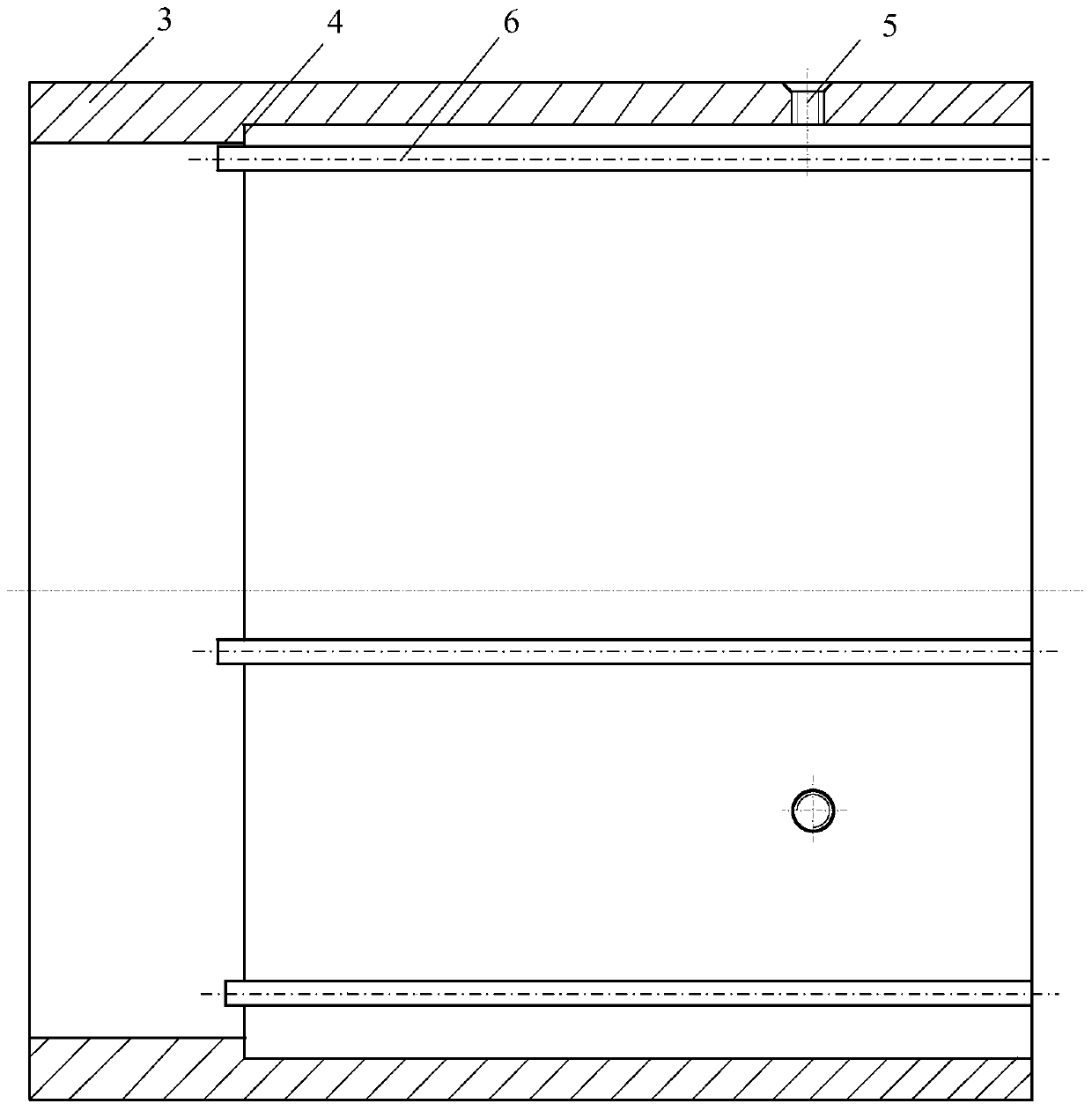

[0053] When molding an amorphous silicon alloy stator core, three semicircles with a radius of 2.6mm are uniformly distribut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com