Synchronous motor self-tuning method suitable for vertical elevator

A synchronous motor and self-tuning technology, which is applied in the direction of motor generator control, electronic commutation motor control, control generator, etc., can solve the problems of low efficiency, complex algorithm, cumbersome steps, etc., and achieve high efficiency, small error, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

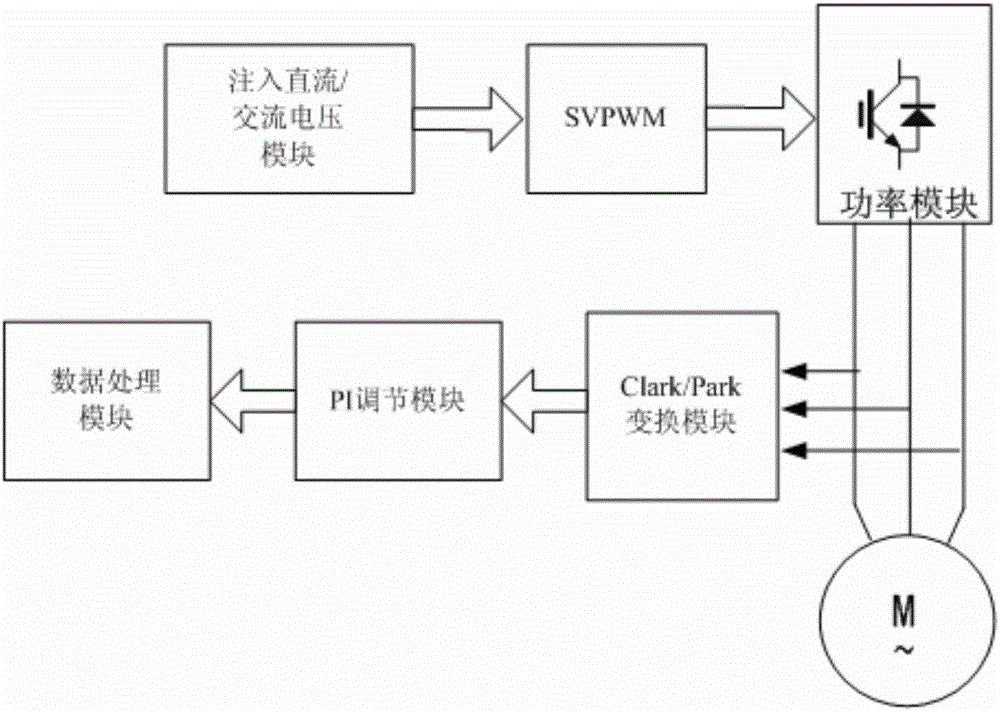

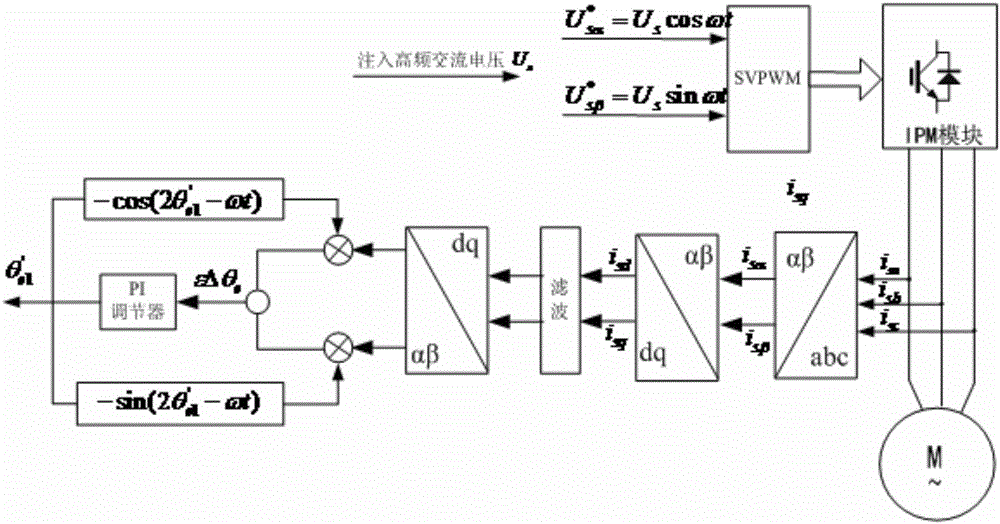

[0029] combine Figure 1 to Figure 4 As shown, a synchronous motor self-tuning method suitable for vertical elevators, including stator resistance tuning steps, stator inductance tuning steps and initial angle tuning steps, wherein:

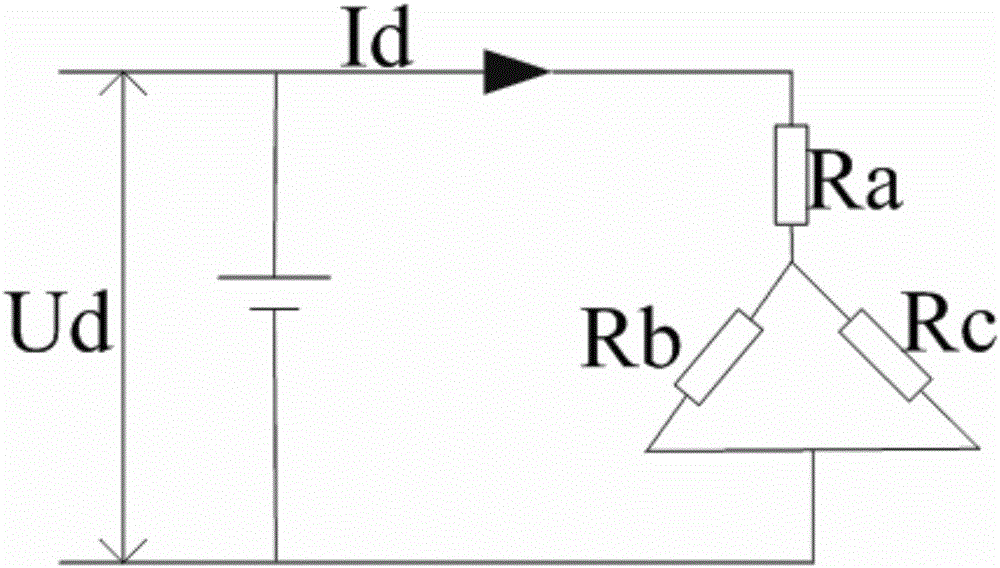

[0030] Stator resistance tuning steps are as follows: use DC injection method to detect stator resistance, inject a certain amplitude of DC voltage into the motor, and record the stable stator phase current I d and equivalent DC voltage U d . The equivalent circuit expression of a synchronous motor is:

[0031] U d = RI d + L d × dI d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com