Shallot pastry and production method thereof

A production method and technology of shallot crisps, which are applied in shallot crisps and its production field, can solve problems such as destruction of beneficial ingredients of shallots, loss of beneficial ingredients, poor color, etc., and achieve the effect of improving taste, flavor, strong fragrance, and crispy taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

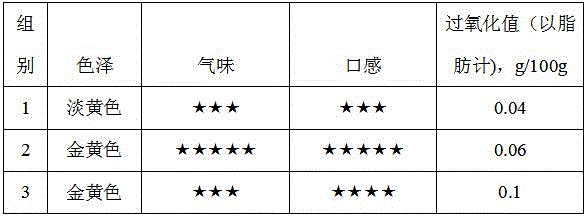

Embodiment 1

[0026] A red onion crisp, made from the following raw materials in parts by weight: 70 parts of fresh shallots, 6 parts of edible cornstarch, 1 part of egg white powder, 0.5 parts of edible salt, and 0.08 parts of spices;

[0027] The spices are composed of star anise powder, cinnamon powder, licorice powder and cumin powder, the weight ratio of which is 10:5:10:13, and the taste is fragrant, which promotes the unique taste and aroma of the product;

[0028] A production method of shallot crisps, comprising the following steps:

[0029] Step 1: Raw material processing, fresh shallots are removed from impurities, peeled, washed and dehydrated, with a moisture content of 2.5%; it is not easy to burn when fried with a low moisture content of 2.5%, which can ensure the color and flavor of the product;

[0030] Step 2: Slicing at low temperature, cut the shallots obtained in step 1 into small pieces of 0.5cm*1cm at 4°C; use low-temperature slices at 4°C to ensure that the beneficia...

Embodiment 2

[0038] A shallot crisp, made from the following raw materials in parts by weight: 80 parts of fresh shallots, 8 parts of starch, 1.5 parts of egg white powder, 0.6 parts of edible salt, and 0.07 parts of spices;

[0039] The spices are composed of star anise powder, cinnamon powder, licorice powder, and cumin powder, with a weight ratio of 15:8:12:16. The flavor is fragrant and promotes the unique taste and aroma of the product;

[0040] Another object of the present invention is to provide a production method of shallot crisps, comprising the following steps:

[0041] Step 1: Raw material processing, fresh shallots are removed from impurities, peeled, moderately dehydrated after cleaning (moisture content 2%);

[0042] Step 2: Slicing at low temperature, cut the shallots obtained in Step 1 into small slices with a width of 1cm*2cm at 3~5°C;

[0043] Step 3: Mix the ingredients, weigh the above ingredients, put them into the mixer, and stir together with the shallot slices in...

Embodiment 3

[0049] A shallot crisp, made of the following raw materials in parts by weight: 80 parts of fresh shallots, 8 parts of edible cornstarch, 1.5 parts of egg white powder, 0.5 parts of edible salt, and 0.07 parts of spices;

[0050] The spices are composed of star anise powder, cinnamon powder, licorice powder, and cumin powder, with a weight ratio of 12:8:15:14, which has a taste and fragrance, and promotes the unique taste and aroma of the product;

[0051] A production method of shallot crisps, comprising the following steps:

[0052] Step 1: Raw material processing, fresh shallots are removed from impurities, peeled, washed and dehydrated, with a moisture content of 2%; it is not easy to burn when low-moisture frying, which can ensure the color and flavor of the product;

[0053] Step 2: Slicing at low temperature, cut the shallots obtained in step 1 into small slices with a width of 0.8cm*1.5cm at 4°C; slicing at low temperature ensures that the beneficial nutrients in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com