A method for automatic on-line production of water chestnut coating pan

An automatic line and coating pot technology, which is applied in food coating, making medicine into special physical or ingestible devices, household components, etc., can solve the problem of high experience requirements for operators, complicated and long production steps, Intra-batch and inter-batch differences are not easy to control, so as to reduce the number of operators, prevent cross-contamination risks, and improve labor safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

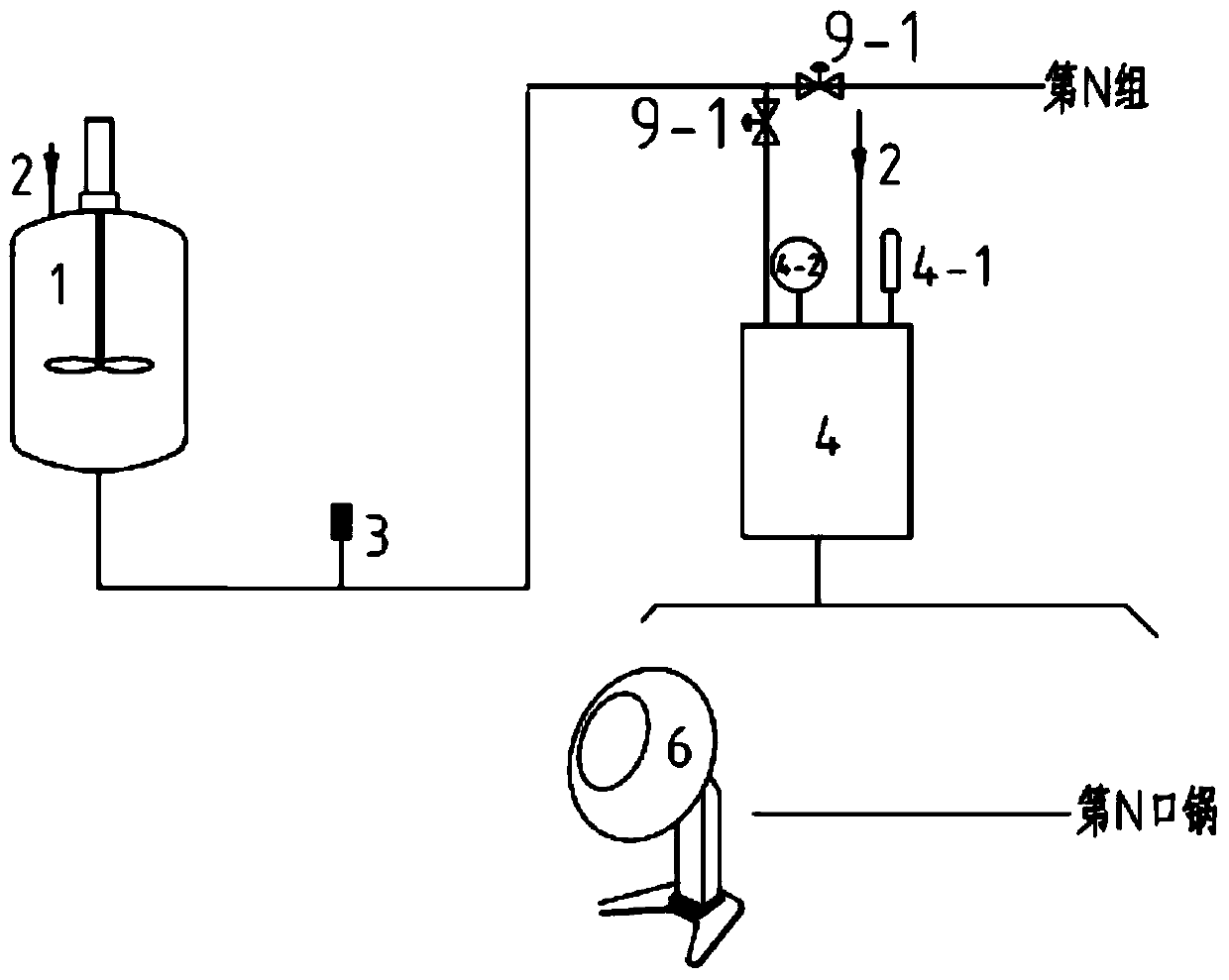

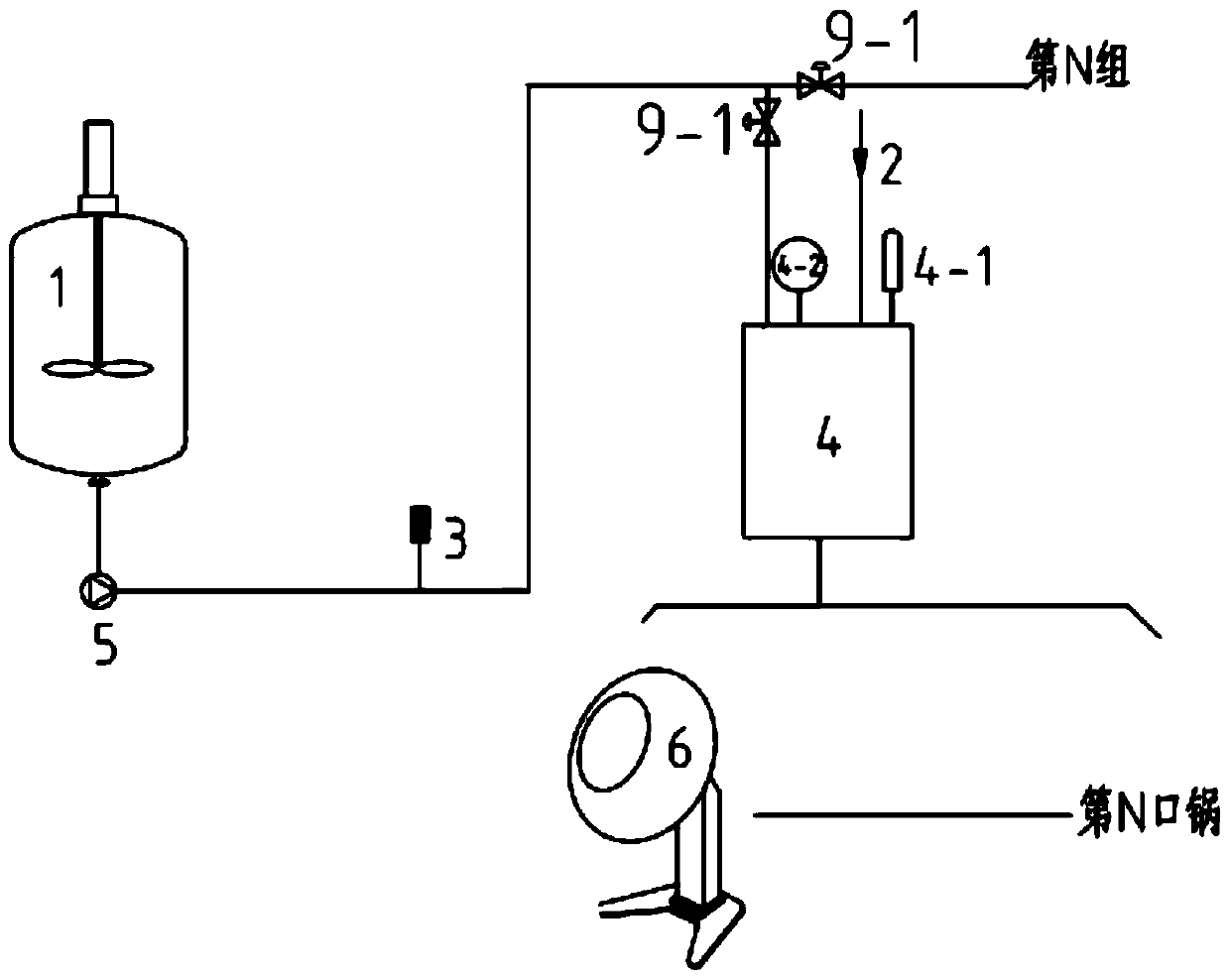

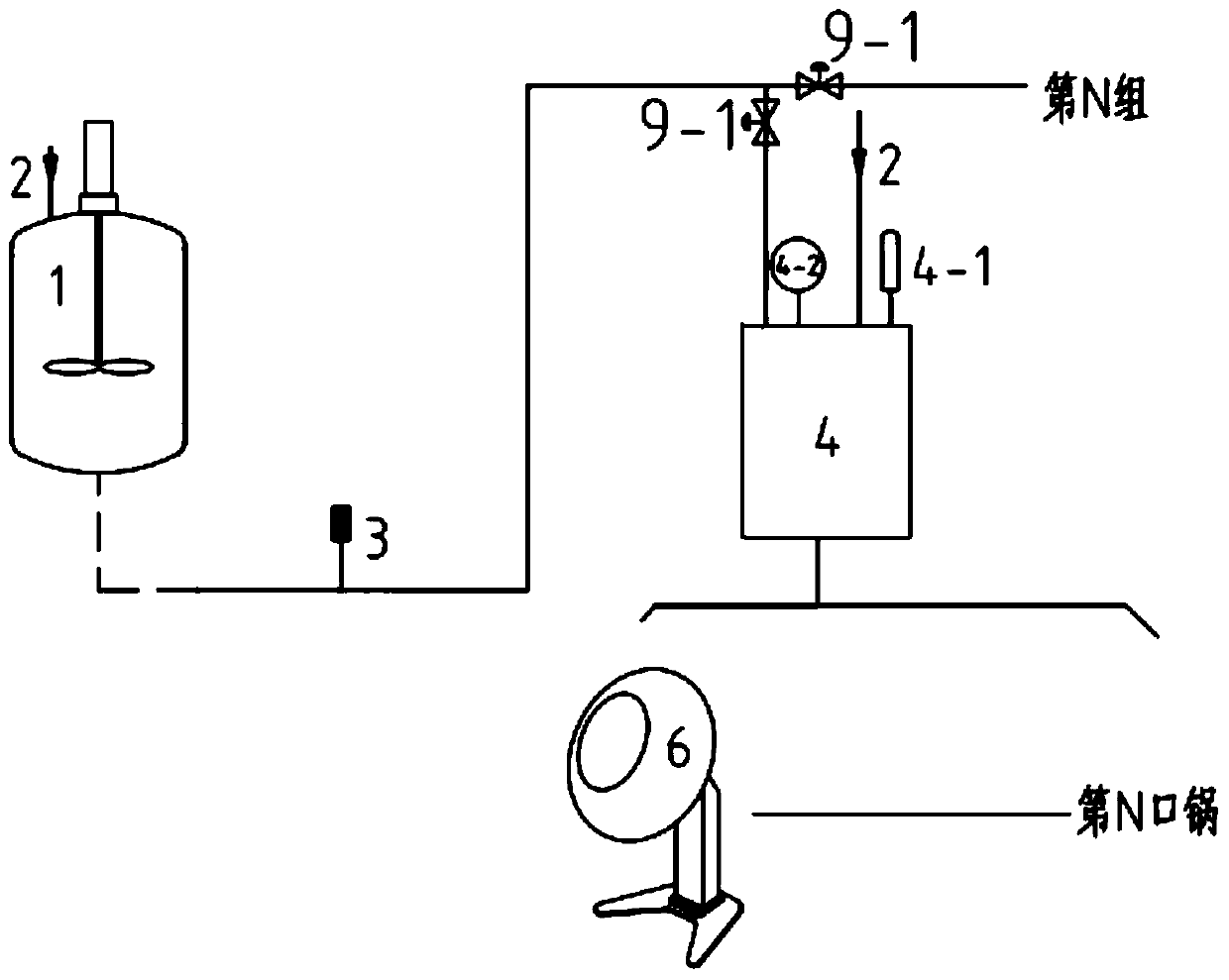

[0061] (1) Automatic filling:

[0062] (a) The pre-prepared syrup is sent to the insulation tank 1 for stirring and preservation;

[0063] (b) Send the feed liquid in the insulation tank 1 through the total liquid addition pipeline and the first liquid addition pipelines connected to the total liquid addition pipeline and equipped with the liquid inlet valve 9-1 into the correspondingly set In each buffer tank 4;

[0064] The liquid level sensors on each of the buffer tanks output liquid level signals to the control system, and the control system compares the read liquid level signals with the set values, and then outputs switch control signals to each liquid inlet valve. When the liquid level stops feeding, it starts feeding when it is lower than the low liquid level.

[0065] When the total liquid volume to be transported is greater than or equal to the pipeline volume of the total liquid feeding pipeline, open the liquid inlet valve on the first liquid feeding pipeline to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com