Modified-nano-hydroxyapatite capable of effectively absorbing methylene blue dyes and preparation method and application of modified-nano-hydroxyapatite

A nano-hydroxyapatite and methylene blue dye technology, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants and other directions, can solve the problems of large discharge of printing and dyeing wastewater, high cost, and difficult biochemical treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The method for preparing modified nano-hydroxyapatite:

[0029] (1) Dissolve humic acid with 0.1mol / L sodium hydroxide solution or potassium hydroxide solution, adjust the pH value to 5.0 with 0.1mol / L hydrochloric acid, add water to form a 1000mg / L aqueous solution.

[0030] (2) Add nano-hydroxyapatite (particle size not exceeding 100nm) to the above aqueous solution to prepare a mixed solution with a mass concentration of nano-hydroxyapatite of 10 g / L, and stir or shake the mixed solution for 24 hours.

[0031] (3) centrifuging to remove the upper layer solution, and freeze-drying the lower layer solid to obtain humic acid-modified modified nano-hydroxyapatite.

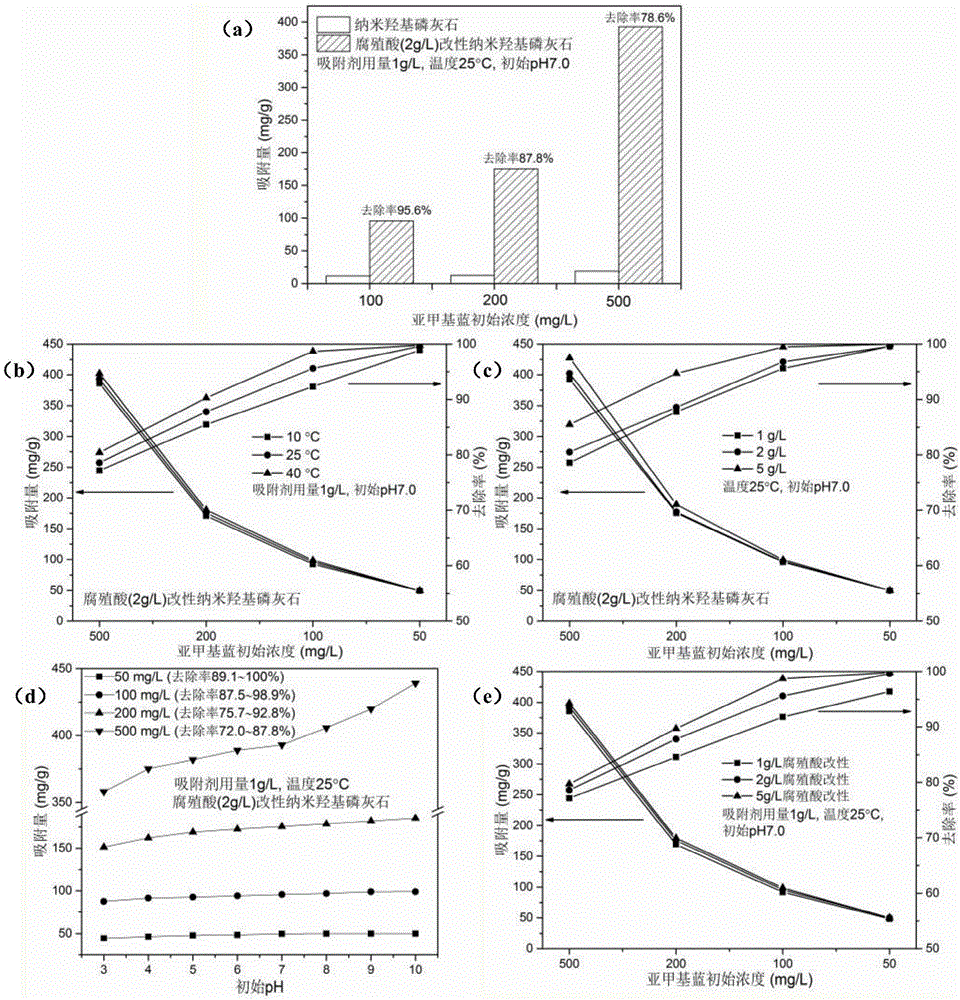

[0032] Application of modified nano-hydroxyapatite to adsorb methylene blue:

[0033] Weigh 50 mg of modified nano-hydroxyapatite into a 150 mL Erlenmeyer flask, add 50 mL of methylene blue solution (pH=7.0) whose methylene blue concentration does not exceed 500 mg / L. Place the Erlenmeyer flask on a shaker ...

Embodiment 2

[0035] The method for preparing modified nano-hydroxyapatite:

[0036] (1) Dissolve humic acid with 0.1mol / L sodium hydroxide solution or potassium hydroxide solution, adjust the pH value to 5.0 with 0.1mol / L hydrochloric acid, add water to form a 2000mg / L aqueous solution.

[0037] (2) Add nano-hydroxyapatite (particle size not exceeding 100nm) to the above aqueous solution to prepare a mixed solution with a mass concentration of nano-hydroxyapatite of 10 g / L, and stir or shake the mixed solution for 24 hours.

[0038] (3) centrifuging to remove the upper layer solution, and freeze-drying the lower layer solid to obtain humic acid-modified modified nano-hydroxyapatite.

[0039] Application of modified nano-hydroxyapatite to adsorb methylene blue:

[0040] Weigh 50 mg of humic acid-modified nano-hydroxyapatite and place it in a 150 mL Erlenmeyer flask, add 50 mL of a methylene blue solution (pH=7.0) whose methylene blue concentration does not exceed 500 mg / L. Place the Erlenme...

Embodiment 3

[0042] The method for preparing modified nano-hydroxyapatite:

[0043] (1) Dissolve humic acid with 0.1mol / L sodium hydroxide solution or potassium hydroxide solution, adjust the pH value to 5.0 with 0.1mol / L hydrochloric acid, add water to form a 5000mg / L aqueous solution.

[0044] (2) Add nano-hydroxyapatite (particle size not exceeding 100nm) to the above aqueous solution to prepare a mixed solution with a mass concentration of nano-hydroxyapatite of 10 g / L, and stir or shake the mixed solution for 24 hours.

[0045] (3) centrifuging to remove the upper layer solution, and freeze-drying the lower layer solid to obtain humic acid-modified modified nano-hydroxyapatite.

[0046] Application of modified nano-hydroxyapatite to adsorb methylene blue:

[0047] Weigh 50 mg of modified nano-hydroxyapatite into a 150 mL Erlenmeyer flask, add 50 mL of methylene blue solution (pH=7.0) whose methylene blue concentration does not exceed 500 mg / L. Place the Erlenmeyer flask on a shaker ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com