Crystallization pressure keeping and increasing method for low-pressure casting molding of aluminum alloy wheel metal mold

A low-pressure casting and metal mold technology, which is applied in the field of crystallization pressure holding and boosting for metal mold low-pressure casting, can solve the problem of difficult to achieve high crystallization boost pressure, improve the solidification feeding effect, and reduce shrinkage porosity and porosity. , to avoid the effect of overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

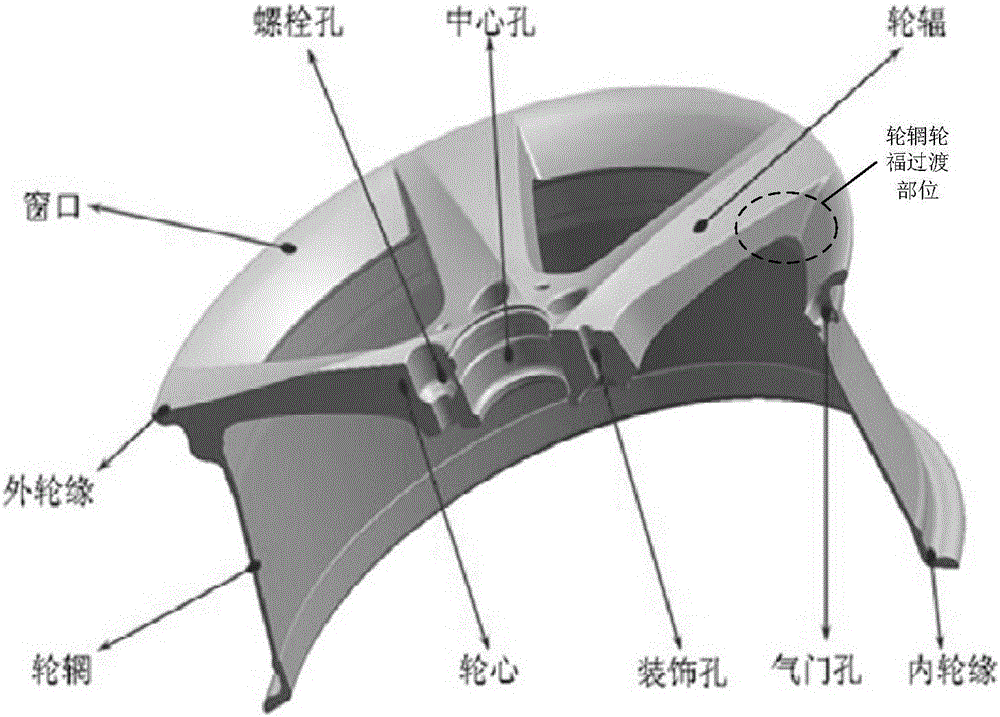

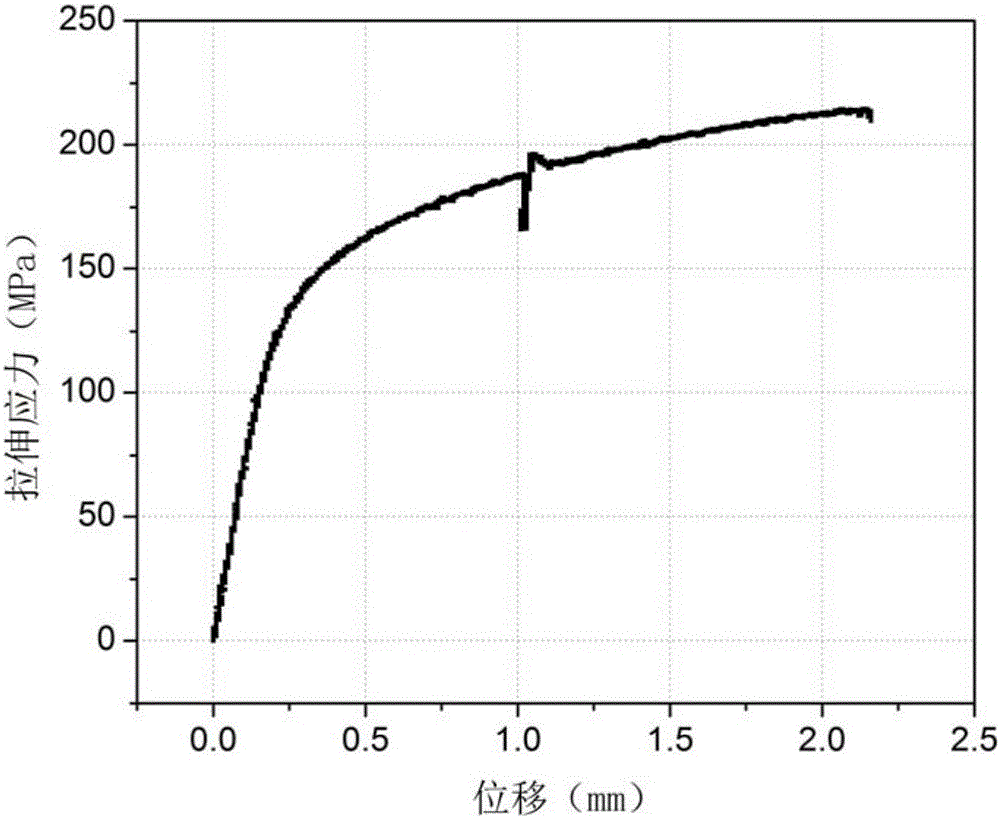

[0092] 26-inch, A356 alloy wheels. H13 steel mold, upper mold + lower mold + 4 side mold structure, directly exposed to the atmosphere. The pouring temperature is 710°C, the initial mold temperature is 400°C, and the cooling method is air cooling.

[0093] The steps of preparing aluminum alloy wheels by adopting metal mold low-pressure casting molding with crystallization pressure-holding and boosting method include:

[0094] Step 1, liquid ascending stage;

[0095] Under the condition that the liquid lifting pressure is 20kPa and the liquid lifting speed is 2.0kPa / s, the aluminum liquid rises steadily along the liquid rising pipe to the gate of the mold and flows into the mold;

[0096] Step 2, the filling stage;

[0097] Under the conditions of the filling pressure of 30kPa and the filling speed of 0.75kPa / s, the molten aluminum is filled into the cavity from the gate until the cavity is completely filled;

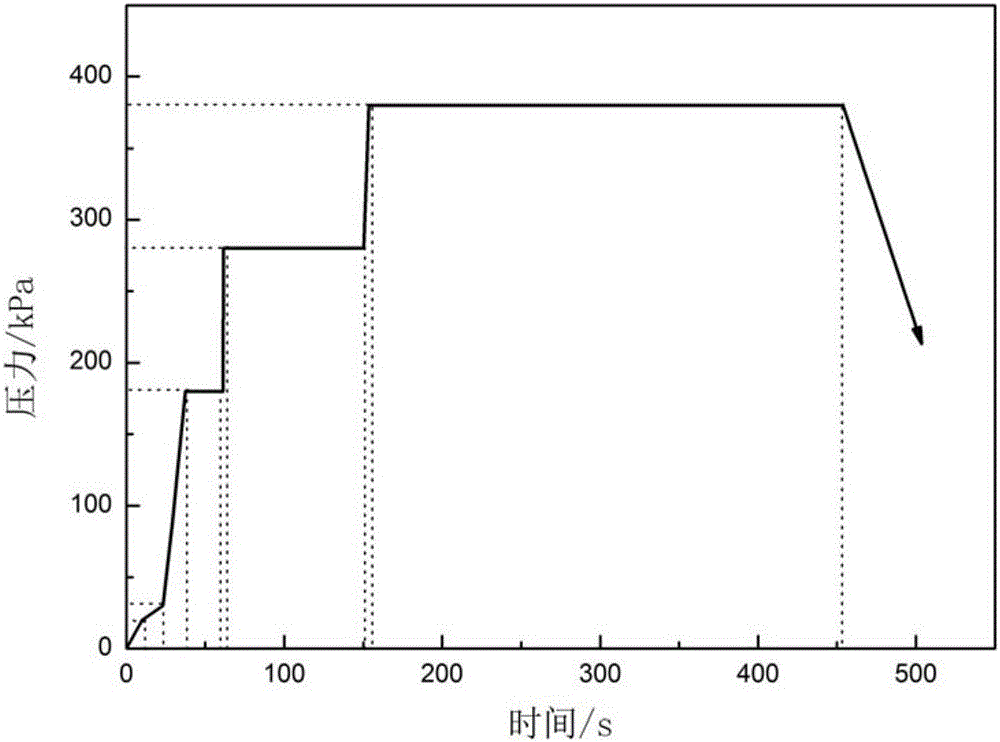

[0098] Step 3, crystallization pressurization stage;

[0099] Af...

Embodiment 2

[0118] 18-inch, A356 alloy wheels. H13 steel mold, upper mold + lower mold + 4 side mold structure, directly exposed to the atmosphere. The pouring temperature is 720°C, the initial mold temperature is 400°C, and the cooling method is wind-mist mixing cooling.

[0119] The steps of preparing aluminum alloy wheels by adopting metal mold low-pressure casting molding with crystallization pressure-holding and boosting method include:

[0120] Step 1, liquid ascending stage;

[0121] Under the conditions of the liquid lifting pressure of 21kPa and the liquid lifting speed of 1.8kPa / s, the aluminum liquid rises steadily along the liquid rising pipe to the gate of the mold and flows into the mold;

[0122] Step 2, the filling stage;

[0123] Under the condition that the filling pressure is 35kPa and the filling speed is 0.54kPa / s, the molten aluminum is filled into the cavity from the gate until the cavity is completely filled;

[0124] Step 3, crystallization pressurization stag...

Embodiment 3

[0143] 20 inches, A356 alloy cast spin wheels. H13 steel mold, upper mold + lower mold + 4 side mold structure, directly exposed to the atmosphere. The pouring temperature is 700°C, the initial mold temperature is 350°C, and the cooling method is wind-mist mixing cooling.

[0144] The steps of preparing aluminum alloy wheels by adopting metal mold low-pressure casting molding with crystallization pressure-holding and boosting method include:

[0145] Step 1, liquid ascending stage;

[0146] Under the conditions of the lifting pressure of 19kPa and the lifting speed of 1.9kPa / s, the aluminum liquid rises steadily along the rising pipe to the gate of the mold and flows into the mold;

[0147] Step 2, the filling stage;

[0148] Under the condition that the filling pressure is 30kPa and the filling speed is 1.0kPa / s, the molten aluminum is filled into the cavity from the gate until the cavity is completely filled;

[0149] Step 3, crystallization pressurization stage;

[015...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com