A traction cross-cutting machine for producing xps profiles

A technology of special-shaped materials and tractors, which is applied in the direction of metal processing, etc., can solve the problems of unsuitable processing of special-shaped materials, low compressive strength of different-shaped materials, time-consuming and labor-intensive secondary processing, etc., and achieve short cutting cycle, fast speed and excellent structure. reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Such as figure 1 As shown, the present invention discloses a traction cross-cutting machine for producing XPS profiles, including traction components 1 and cross-cutting components 2 connected in sequence, wherein a length calculation sensor 112 is installed on the traction component 1, the length calculation sensor 112 and the cross-cutting The transmission system servo motor 22 on the cutting part 2 is electrically connected.

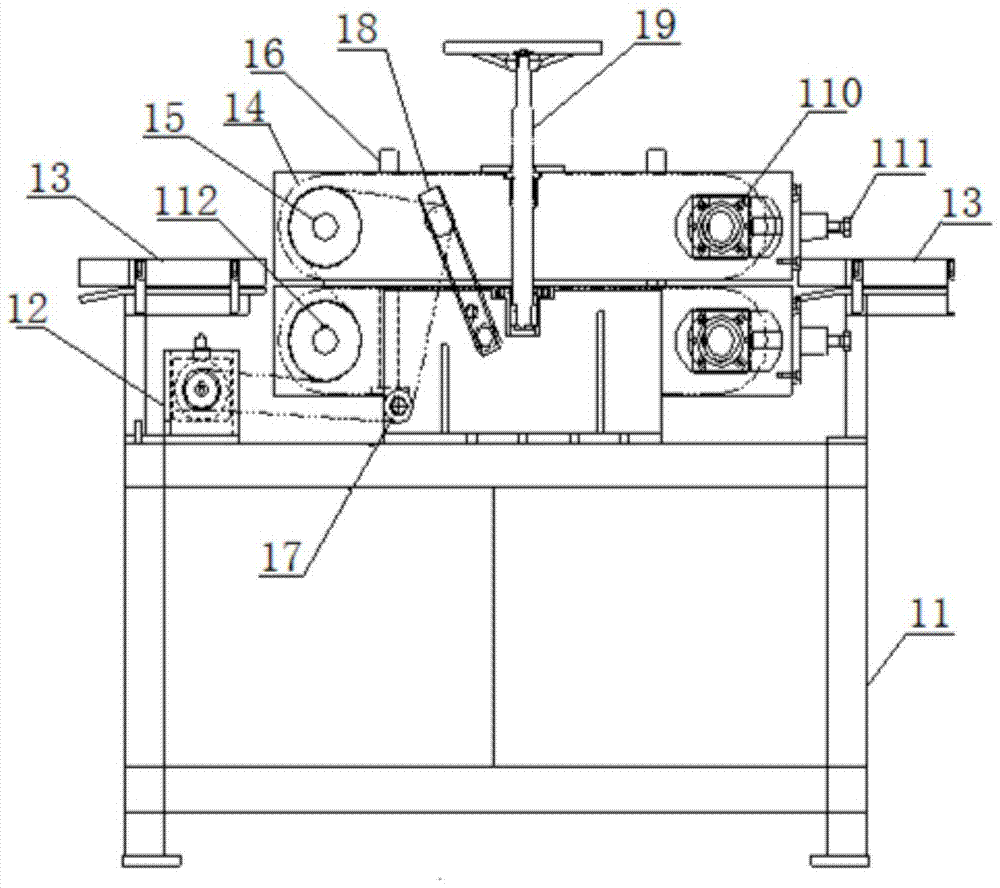

[0015] Such as figure 2 Shown is a schematic diagram of the structure of the traction unit 1, the traction unit 1 includes a traction frame 11, a traction motor 12, a profiled bar stopper 13, a traction pulley 14, a tractor drive shaft component 15, a vertically moving guide assembly 16, and a synchronous belt guide Wheel component 17, drive belt tensioning component 18, up and down adjustment mechanism assembly 19, traction machine driven shaft component 110 and traction belt transverse tensioning mechanism 111, traction motor 12 is installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com