Preparation method of lamellar porous graphene oxide and product of preparation method

A technology of graphene and sheets, which is applied in the field of preparation of sheet-layer porous graphene oxide, can solve the problems of irregular nucleation process and limited application of directional freezing method, and achieve the effect of low cost, sufficient raw materials, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] (1) Dissolve 20mgGO and 10mgPVA in 4mlH at 20°C 2 O, Ultrasound in an ultrasonic cell pulverizer for 5 minutes to fully dissolve, and vacuum remove air bubbles to obtain a homogeneous solution, wherein the concentration of GO in the solution is 5.0mg / mL, and the concentration of the binder in the solution is 2.5mg / mL;

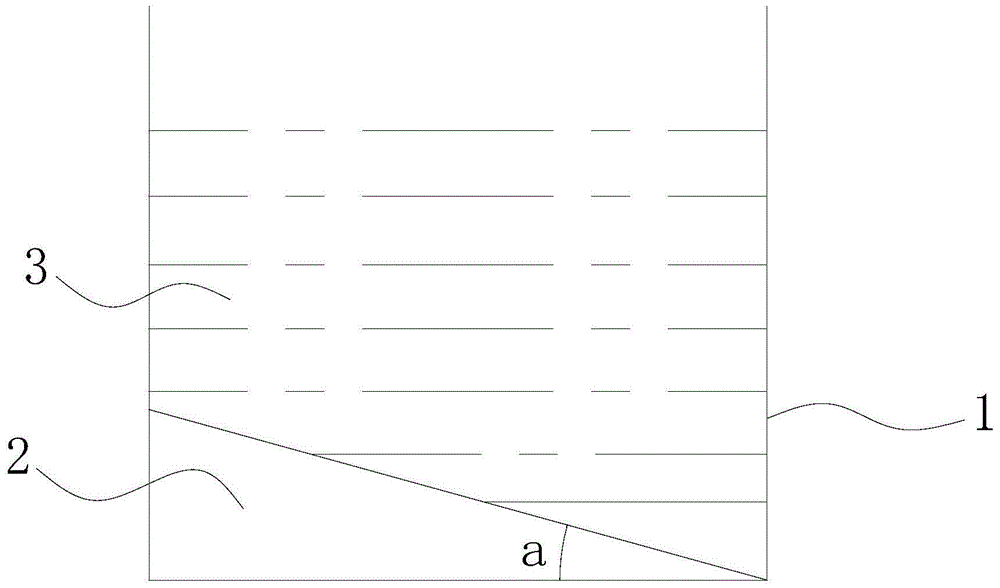

[0050] (2) Place the solution obtained in step (1) in a container with a wedge-shaped silicone rubber device. The slope of the wedge-shaped silicone rubber device is 15°, and use frozen ethanol (-90°C) as the cold source to perform two-way freezing to obtain the intermediate product;

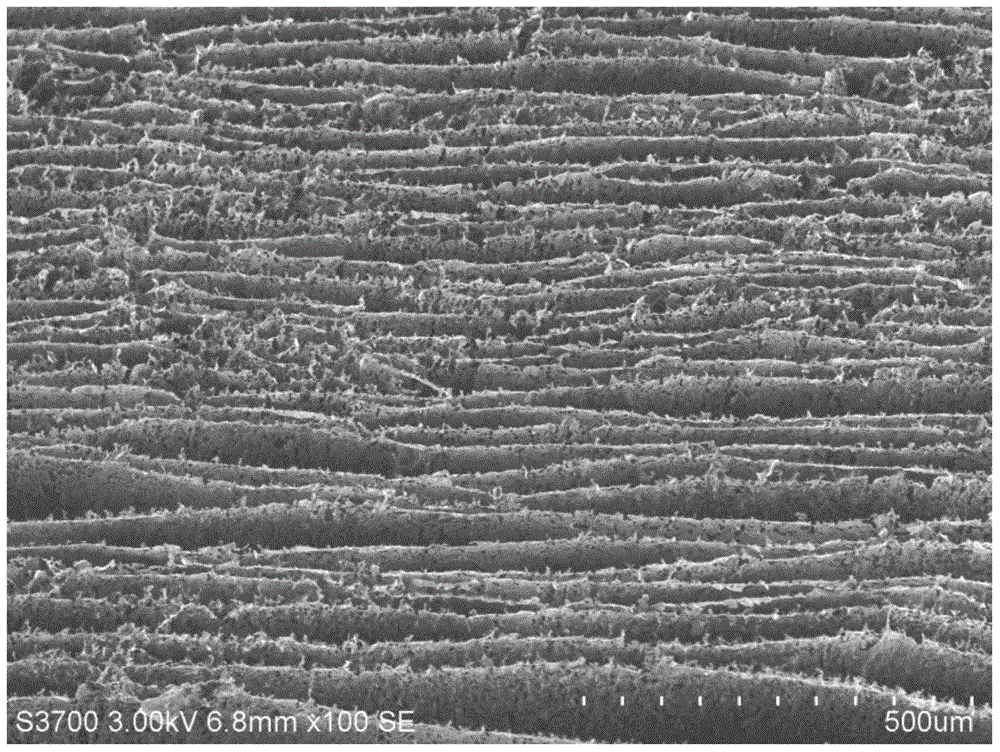

[0051] (3) Freeze-drying the intermediate product obtained in step (2) for 24 hours to remove the solvent to obtain lamellar porous graphene oxide, which has a regular layered porous structure with large-area orientation.

Embodiment 2

[0053] (1) Dissolve 20mgGO and 20mgPVA in 4mlH at 20°C 2 O, Ultrasound in an ultrasonic cell pulverizer for 5 minutes to fully dissolve, and vacuum remove air bubbles to obtain a homogeneous solution, wherein the concentration of GO in the solution is 5.0 mg / mL, and the concentration of the binder in the solution is 5.0 mg / mL;

[0054] (2) Place the solution obtained in step (1) in a container with a wedge-shaped silicone rubber device. The slope of the wedge-shaped silicone rubber device is 15°, and use frozen ethanol (-90°C) as the cold source to perform two-way freezing to obtain the intermediate product;

[0055] (3) Freeze-drying the intermediate product obtained in step (2) for 24 hours to remove the solvent to obtain porous graphene oxide, which has a regular layered porous structure with large-area orientation.

Embodiment 3

[0057] (1) Dissolve 20mgGO and 40mgPVA in 4mlH at 20°C 2 O, Ultrasound in an ultrasonic cell pulverizer for 5 minutes to fully dissolve, remove air bubbles in a vacuum to obtain a homogeneous solution, wherein the concentration of GO in the solution is 5.0mg / mL, and the concentration of the binder in the solution is 10.0mg / mL;

[0058] (2) The solution obtained in step (1) is placed in a container with a wedge-shaped silicone rubber device, the slope of the wedge-shaped silicone rubber device is 15°, and it is subjected to two-way freezing with frozen ethanol (-90° C.) as a cold source to obtain mid product;

[0059] (3) Freeze-drying the intermediate product obtained in step (2) for 24 hours to remove the solvent to obtain porous graphene oxide, which has a regular layered porous structure with large-area orientation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com