Organosilicone high-boiling-component removing and low-boiling-component removing tower pressure-variable thermal coupling distillation method and equipment

A technology for stripping towers and organic silicon, applied in the fields of silicon organic compounds, organic chemistry, chemical instruments and methods, etc., can solve the problems of high energy consumption and large consumption, and achieve energy saving, energy consumption reduction, and energy consumption reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

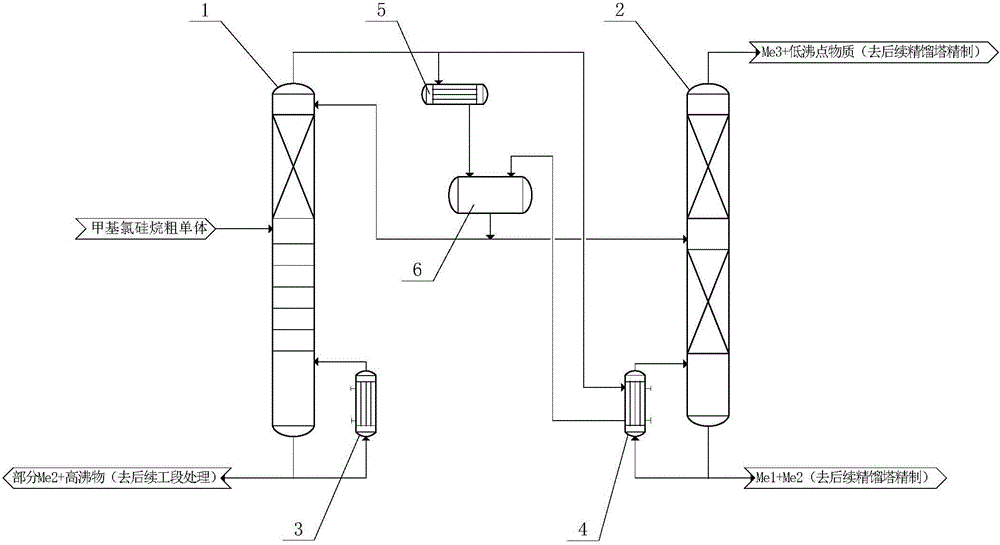

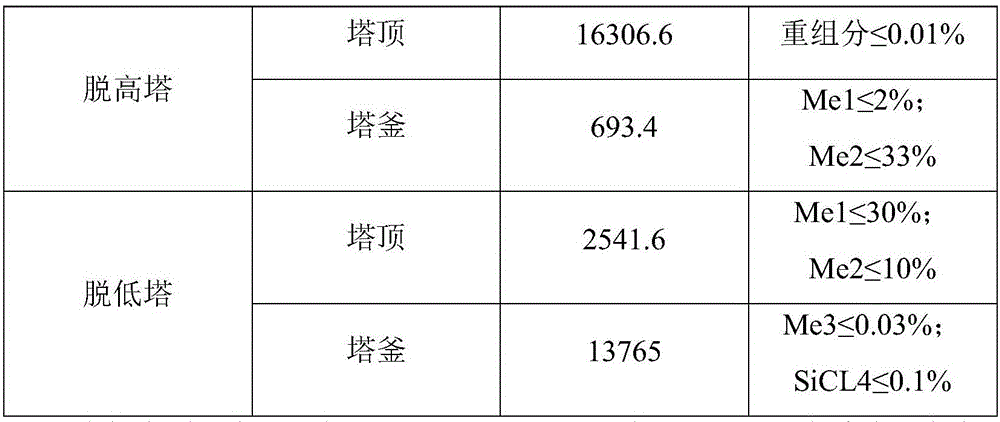

[0022] Such as figure 1 As shown, the methyl chlorosilane crude monomer separation and removal process, the total feed rate of the crude monomer is 17000Kg / hr, which is recorded in mass fraction: the content of Me2 is 78%, the content of Me1 is 7.18%, and the content of Me3 The content is 7.3%, and the remaining high boiling substances and low boiling substances are 7.52%. The raw material enters the de-elevation tower 1 (high pressure), and the heavy components are extracted from the tower kettle, including part of dimethyldichlorosilane (Me2) and high boilers with a higher boiling point than dimethyldichlorosilane (Me2); Dimethyldichlorosilane (Me2) and lower light components than Dimethyldichlorosilane (Me2). The gaseous phase material at the top of the de-elevation tower 1 (high pressure) enters the reboiler 4 of the de-elevation tower 2 (low pressure) as a heat source. After coming out of the de-lowering tower reboiler, it enters the de-higher tower 1 (high pressure) to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com