A New Structure Coke Quenching Oven

A new type of structure and coke quenching oven technology, which is applied in coke ovens, coke cooling, petroleum industry, etc., can solve the problems of large indentation height of refractory bricks, affecting normal production, and high support strength of corbels, so as to reduce electricity consumption. Consumption, prolong contact and residence time, increase the effect of distribution uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

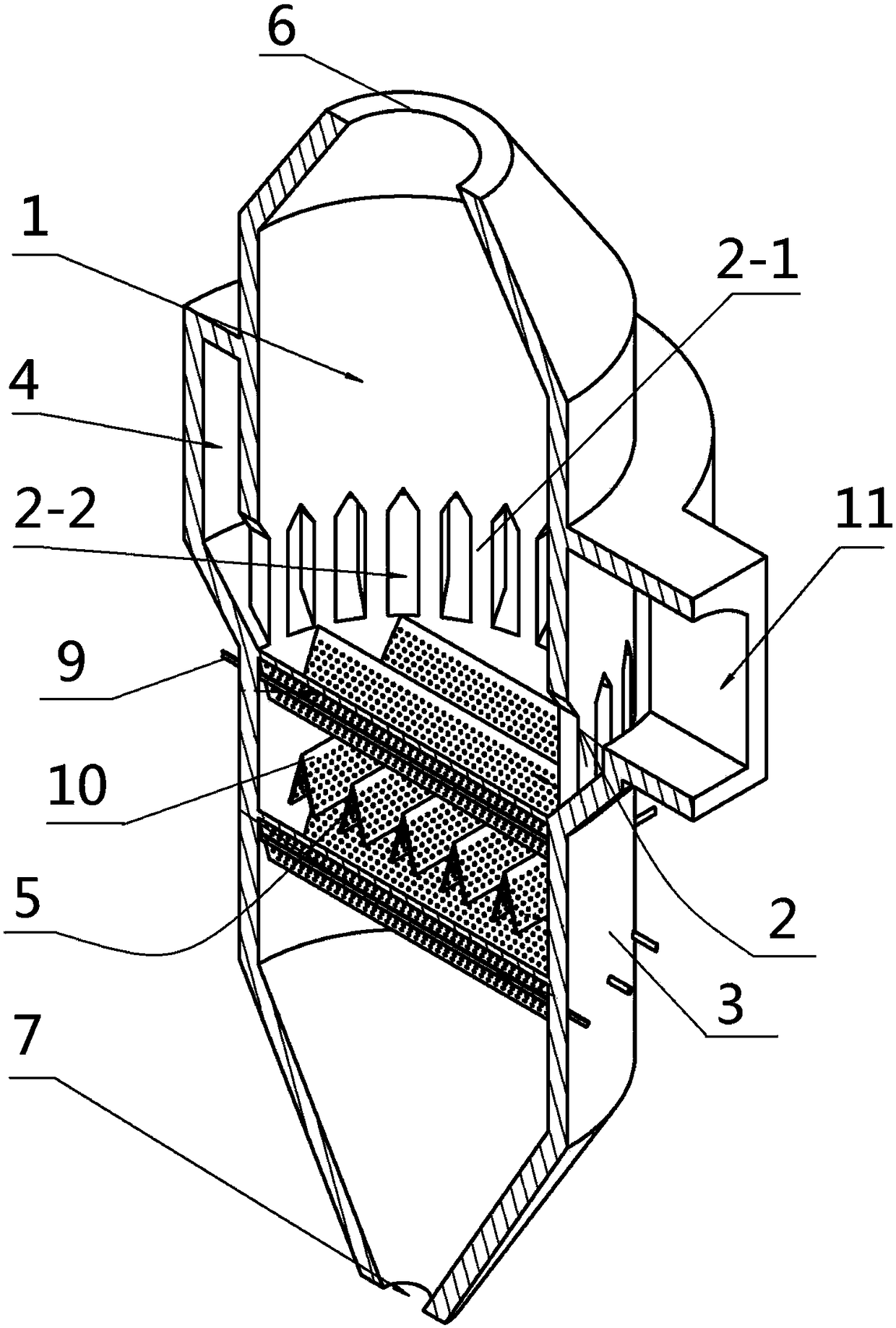

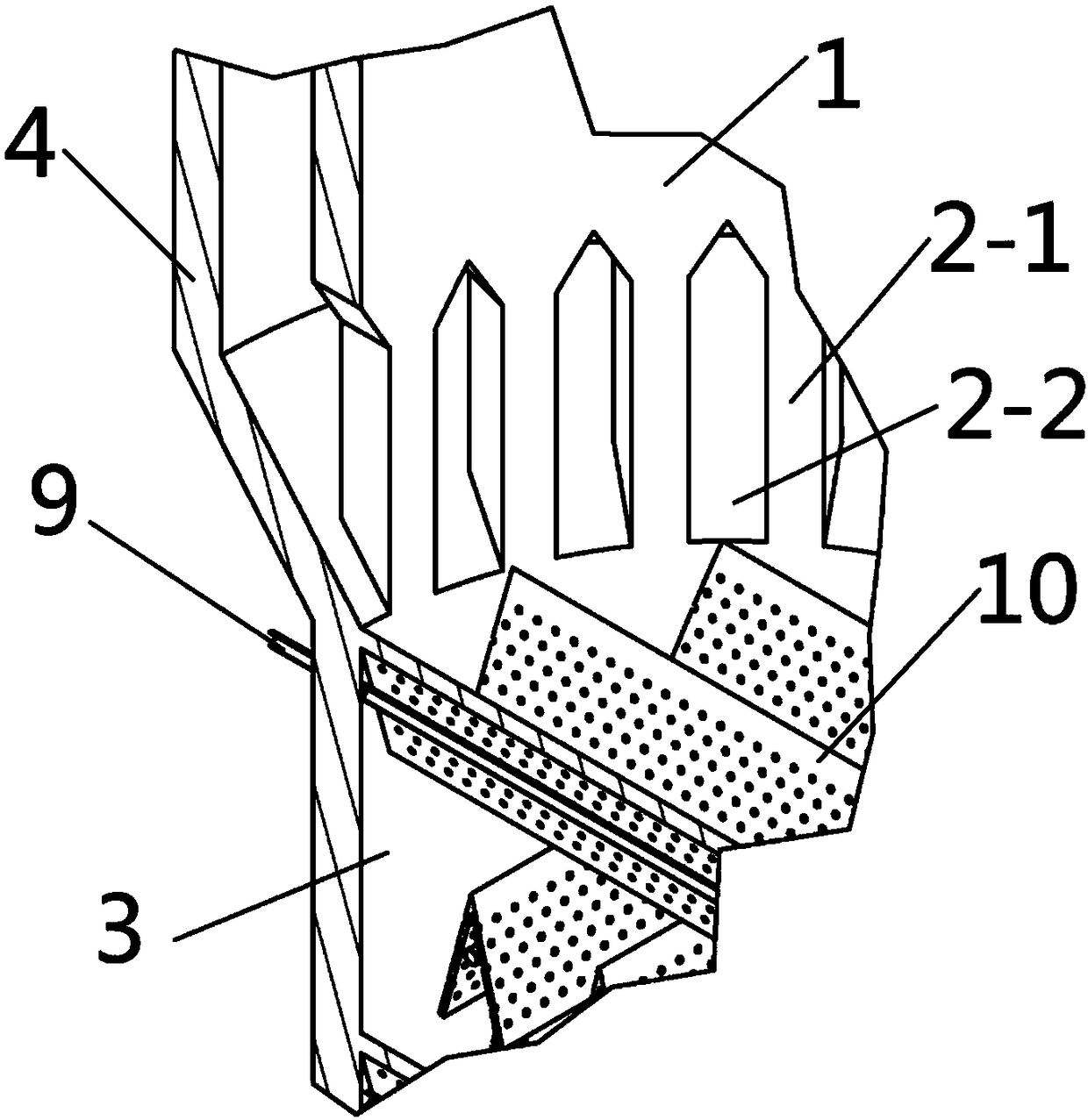

Embodiment 1

[0052] Fast coke quenching scheme:

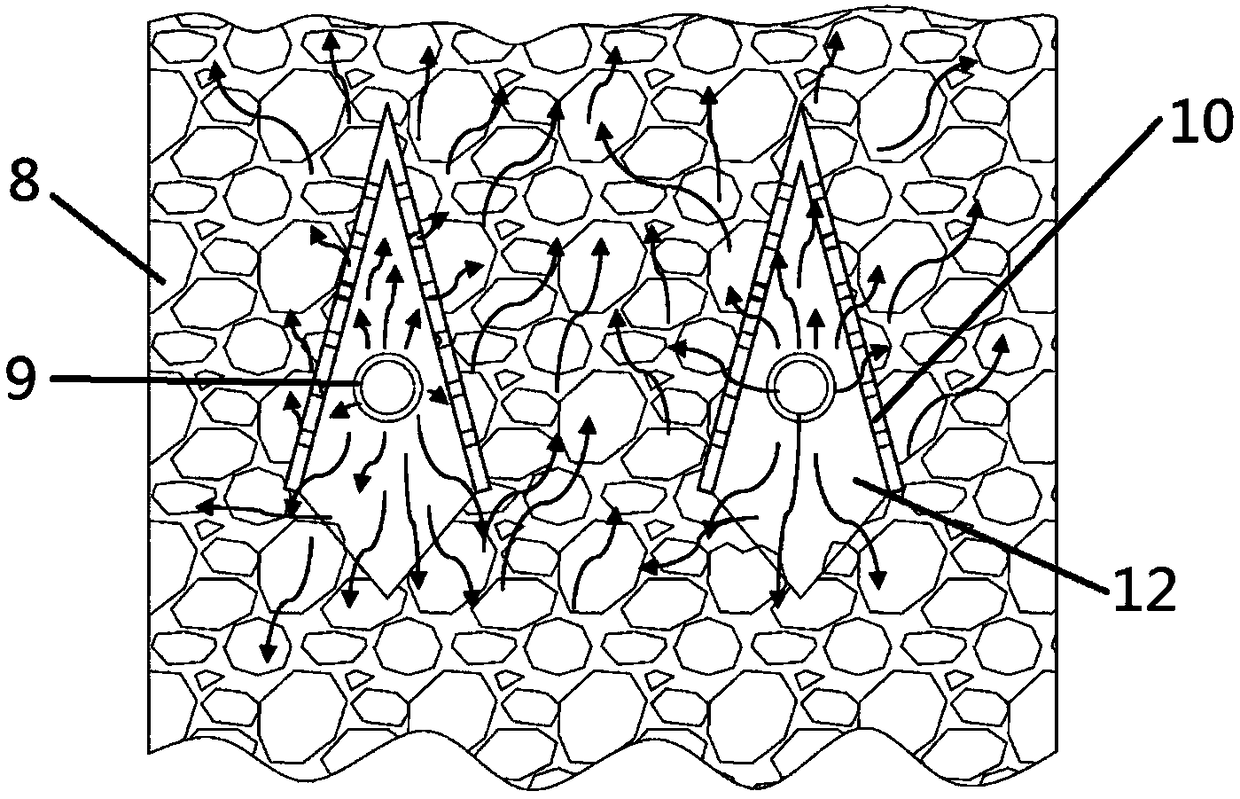

[0053] The purpose of this scheme is to quickly quench coke and produce as little syngas as possible to ensure the quality of cold coke. During the coke quenching process, the red hot coke is loaded into the pre-storage section 1 at intervals. When the temperature of the first distribution plate 5 from top to bottom is displayed as 300°C, the program-controlled valve connected to the cooling medium nozzle 9 below it is opened to filter The coking wastewater from which solid particles have been removed is slowly sprayed into the diamond-shaped area 12 below the V-shaped plate 10 . In this area, the atomized water sprayed from the nozzle directly contacts the falling red hot coke 8, and is immediately vaporized into steam. The superheated steam is formed through the red coke layer through the gap, and the combustible gas phase (mainly CH 4 、H 2 , CO and other components), water gas and a small amount of fine coke powder generated by the re...

Embodiment 2

[0059] Prolific syngas solution:

[0060] Under the conditions of guaranteeing the strength and ash index of coke, the purpose of this scheme is to produce as much syngas as possible. Its operation process is basically the same as that of Embodiment 2, but the coke oven gas is introduced into the distribution plate 5 of the first and second layers as cooling medium, and the distribution plate 5 of the third layer continues to spray water. The role of introducing coking gas is to convert steam and methane in coke oven gas under the catalytic action of high temperature and red heat to produce more synthesis gas. The temperature control index of each distribution plate is controlled as follows: the distribution plate 5 of the first layer is 800°C, the distribution plate 5 of the second layer is 600°C, and the distribution plate 5 of the third layer is 180°C. The water spray is mainly concentrated at the distribution plate 5 of the third layer, where low-temperature coke is used ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com