Bourrache officinale deep processing method and deep processing product thereof

A technology of borage and deep processing, which is applied in the directions of producing fat, pharmaceutical formulations, plant raw materials, etc., can solve the problems of low utilization efficiency, single processing and application methods of borage, and achieves the effect of improving utilization efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

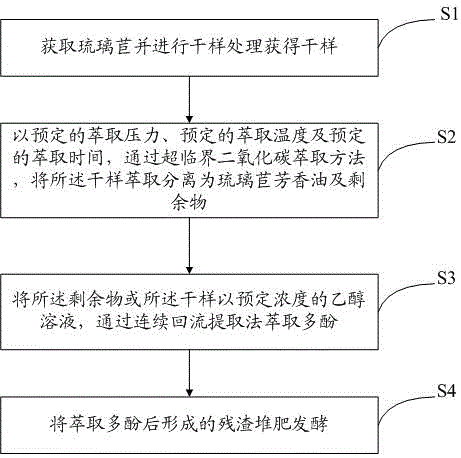

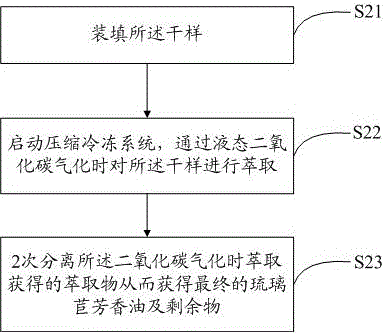

Method used

Image

Examples

Embodiment 1

[0061] Orthogonal experimental design and experimental results of supercritical carbon dioxide aromatic oil extraction:

[0062] Table I

[0063]

[0064] As shown in the table above, A3B1C3D2 (treatment group 7) has the highest extraction volume among the 9 treatment combinations, that is, the extraction pressure is 20MPa, the extraction temperature is 35°C, the extraction time is 2.5h, and the extraction flow rate is 2.5L / h. The extraction volume of this combination is 0.315 g, the aromatic oil content is 0.63%.

[0065] However, by comparing the average extraction volume, it can be found that the optimal parameter combination should be A3B1C2D3. Therefore, further verification experiments are required.

[0066] A verification experiment was performed on the A3B1C2D3 combination. The experimental results are: the average extraction amount of the A3B1C2D3 combination is 0.342g, and the aromatic oil content is 0.68%.

[0067] Therefore, the optimal combination of borage...

Embodiment 2

[0069] Orthogonal Experimental Design and Experimental Results of Borage Polyphenols Extraction

[0070] Table II

[0071]

[0072] As shown in Table 2, the optimal combination of polyphenol extraction process parameters should be: ethanol concentration 25%, extraction temperature 65°C, extraction time 90min, and solid-liquid ratio 1:20.

[0073] When using this combination of parameters for extraction, the amount of polyphenols extracted from borage was 13.50mg / g dry sample.

[0074] In summary, the present invention provides a borage deep processing method and its deep processing products. A supercritical fluid is used to extract the active substance components of the aromatic oil in borage, and a continuous reflux extraction method is used to further extract the polyphenols in the remaining substance after extracting the aromatic oil.

[0075] The above-mentioned deep processing process can be carried out by using the aerial parts after seed collection, which realizes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com