Preparation method of pearl barley and honey vinegar

A technology of honey vinegar and barley, which is applied in the preparation of vinegar, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of poor taste of barley vinegar, complicated processes, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

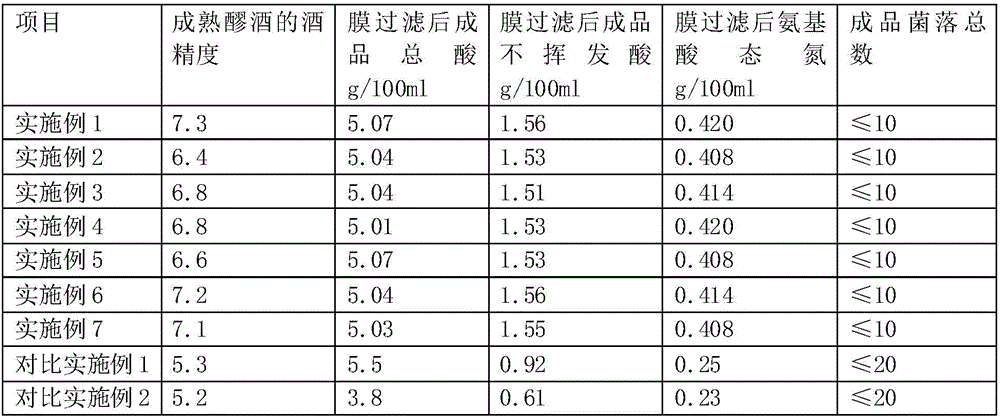

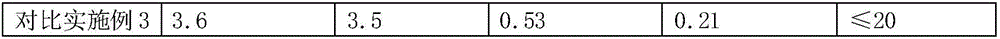

Examples

Embodiment 1

[0027] (1) Processing of raw materials (with barley as the starchy raw material, the feeding base is 1500kg per batch):

[0028] a, crushed barley: 80% pass through a 40-mesh sieve, and 20% pass through a 10-mesh sieve;

[0029] b. Saccharification Daqu: use Aspergillus Usami As3.758 and Aspergillus niger As3.350 to make koji respectively, and then mix the finished koji made by Aspergillus Usami and the finished koji made by Aspergillus niger in a mass ratio of 4:1, requiring glucoamylase activity ≥ 800μ, acid protease activity ≥ 200μ;

[0030] c. Active alcoholic yeast: 1.5kg alcoholic active dry yeast, activated with 30°C warm water and 5% sugar water for half an hour:

[0031] (2) Blending: mix according to the mass ratio of barley flour and water of 1:5, mix 1500kg of barley flour and water evenly; then add 600kg of compound saccharified Daqu, and mix evenly with 4.5kg of flavor-enhancing red yeast rice; Adjust the mash temperature to 30±2°C;

[0032] (3) Saccharificati...

Embodiment 2

[0040] Embodiment 2 A kind of preparation method of barley honey vinegar

[0041] (1) Processing of raw materials (with barley as the starchy raw material, the feeding base is 1500kg per batch):

[0042] a. Crush barley: 70% pass through a 40-mesh sieve, 30% pass through a 10-mesh sieve, mixed in proportion when feeding;

[0043] b. Saccharification Dakoji: use Aspergillus Usami and Aspergillus niger to make koji separately, and then mix the finished koji made by Aspergillus Usami and the finished koji made by Aspergillus niger at a mass ratio of 4:1, requiring glucoamylase activity ≥ 800μ, acid protease activity ≥ 200μ;

[0044] c. Active alcohol yeast: 1.5kg alcohol active dry yeast, activated with 30°C warm water and 5% sugar water for half an hour;

[0045] (2) Mixing: According to the ratio of 1:6, mix 1500kg of barley powder and water evenly; then add 750kg of compound saccharification Daqu, and mix evenly with 4.5kg of fragrant red yeast rice; adjust the temperature o...

Embodiment 3

[0055] (1) Processing of raw materials (with barley as the starchy raw material, the feeding base is 1500kg per batch):

[0056] a, barley pulverization: 90% pass through the 40 mesh sieve, 100% pass through the 10 mesh sieve;

[0057] b. Saccharification Dakoji: use Aspergillus Usami and Aspergillus niger to make koji separately, and then mix the finished koji made by Aspergillus Usami and the finished koji made by Aspergillus niger at a mass ratio of 4:1, requiring glucoamylase activity ≥ 800μ, acid protease activity ≥ 200μ;

[0058] c. Active alcoholic yeast: 1.5kg alcoholic active dry yeast, activated with warm water at 32°C and 5% sugar water for 35 minutes:

[0059] (2) Mixing: mix according to the mass ratio of barley flour and water of 1:5.5, mix 1500kg of barley flour and water evenly; then add 700kg of compound saccharified Daqu, and mix evenly with 3.5kg of flavor-enhancing red yeast rice; Adjust the mash temperature to 30±2°C;

[0060] (3) Saccharification and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com