Method for dynamically judging state of slags in converter smelting process

A converter smelting and slag technology is applied in the field of dynamically judging the slag state in the converter smelting process, which can solve the problems that the slag state cannot be reflected thoroughly, the difference of the slag state, and cannot be accurately judged, so as to avoid slag splashing. Or the effect of re-drying accidents, stabilizing the production of 120 tons of converters, and ensuring the quality of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

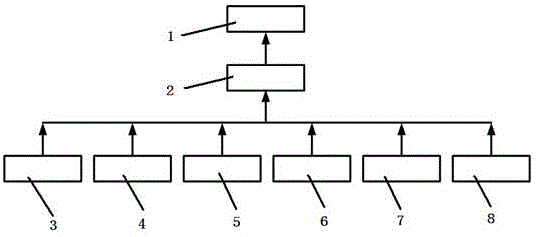

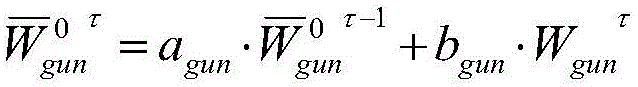

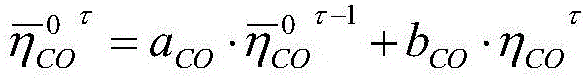

[0162] In the pre-converter smelting stage, the height H from the furnace bottom to the furnace mouth in the converter is input to the slag state detection smelting computer 1 Bof is 8.5m, the mass of molten iron added to the converter is W iron is 105 ton, the quality of steel scrap added to the converter is W fg It is 10 tons. Additionally, setting a gun =0.1,b gun =0.9, a 氧气 =0.1,b 氧气 =0.9, a 烟气 =0.1,b 烟气 =0.9, a CO =0.1,b CO =0.9, a S =0.1,b S = 0.9.

[0163] The slag state detection computer 1 respectively detects and analyzes the data related to judging the slag state through the intermediate communication PLC2 according to the acquisition period of 1s:

[0164] Through the feedback and analysis of the oxygen flow sensor 3, the stable flow of oxygen at the current moment in the converter smelting stage is obtained 5.83m 3 / s;

[0165] Through the feedback and analysis of the gravity sensor, the stable quality of the oxygen lance at the last moment befor...

example 2

[0185] In the pre-converter smelting stage, the height H from the furnace bottom to the furnace mouth in the converter is input to the slag state detection smelting computer 1 Bof is 8.5m, the mass of molten iron added to the converter is W iron is 110ton, the quality of steel scrap added to the converter is W fg It is 8 tons. Additionally, setting a gun =0.15,b gun =0.85, a 氧气 =0.15,b 氧气 =0.85, a 烟气 =0.15,b 烟气 =0.85, a CO =0.15,b CO =0.85, a S =0.15,b S = 0.85.

[0186] The slag state detection computer 1 respectively detects and analyzes the data related to judging the slag state through the intermediate communication PLC2 according to the acquisition cycle of 1.5s:

[0187] Through the feedback and analysis of the oxygen flow sensor 3, the stable flow of oxygen at the current moment in the converter smelting stage is obtained 5.90m 3 / s;

[0188] Through the feedback and analysis of the gravity sensor, the stable quality of the oxygen lance at the last mom...

example 3

[0208] In the pre-converter smelting stage, the height H from the furnace bottom to the furnace mouth in the converter is input to the slag state detection smelting computer 1 Bof is 8.5m, the mass of molten iron added to the converter is W iron is 106 ton, the quality of steel scrap added to the converter is W fg It is 10 tons. Additionally, setting a gun =0.2,b gun =0.8, a 氧气 =0.2,b 氧气 =0.8, a 烟气 =0.2,b 烟气 =0.8, a CO =0.2,b CO =0.8, a S =0.2,b S = 0.8.

[0209] The slag state detection computer 1 respectively detects and analyzes the data related to judging the state of slag through the intermediate communication PLC2 according to the acquisition cycle of 2s:

[0210] Through the feedback and analysis of the oxygen flow sensor 3, the stable flow of oxygen at the current moment in the converter smelting stage is obtained 5.85m 3 / s;

[0211] Through the feedback and analysis of the gravity sensor, the stable quality of the oxygen lance at the last moment bef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com