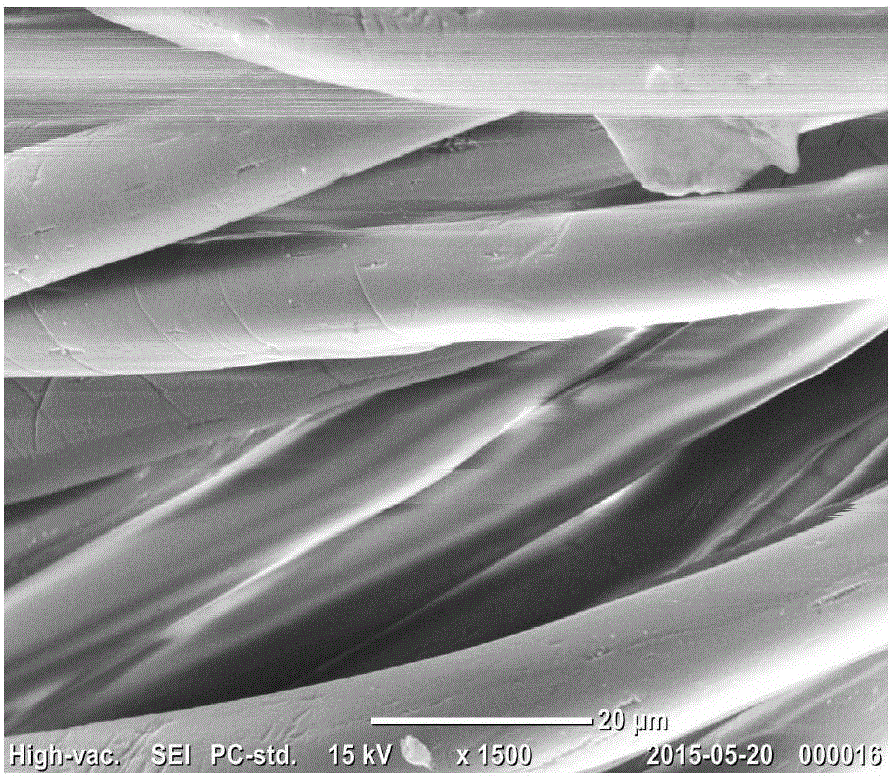

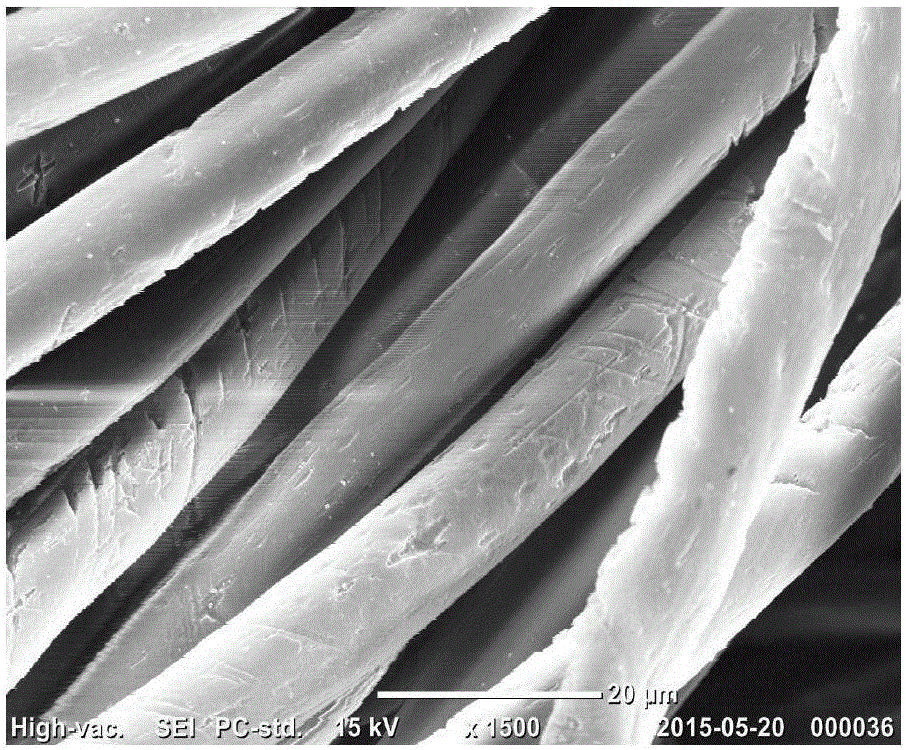

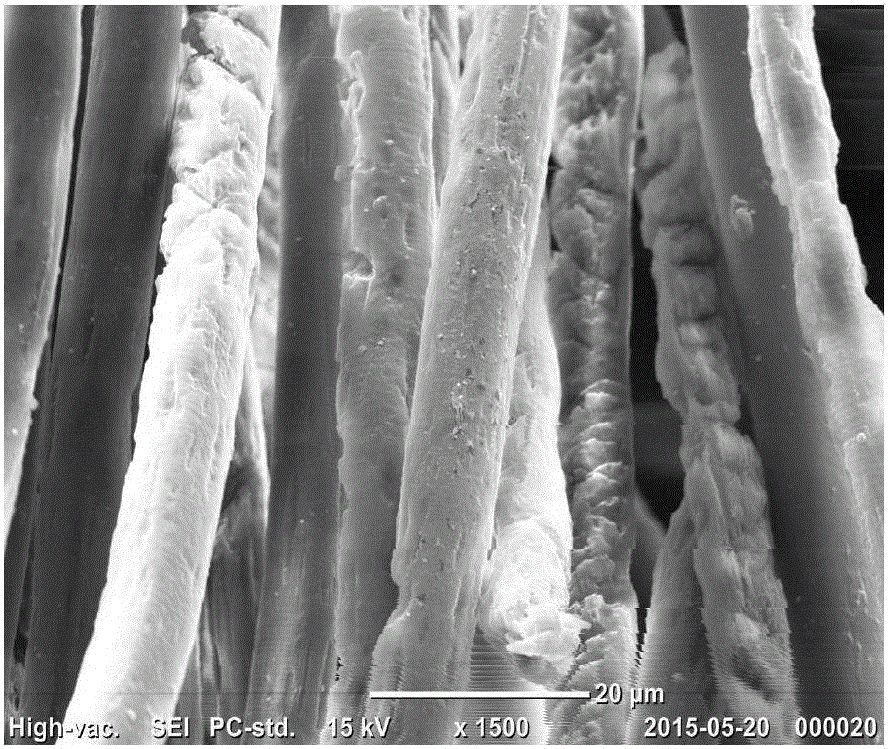

Alkali deweighting finishing process of moisture-absorption and quick-drying fabric based on regenerated polyester fibers

A recycled polyester, moisture-absorbing and quick-drying technology, which is applied in fiber treatment, textile material treatment, animal fiber, etc., can solve the problems of high fiber rigidity, high elongation at break, low fiber moisture regain, etc., and achieve low loss of fabric strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of alkali reduction finishing process of moisture-absorbing and quick-drying fabrics based on regenerated polyester fibers in this embodiment includes the following steps: firstly, the blended fabrics of raw materials in the following weight percentages are used: 85% regenerated polyester fibers (regenerated polyester used) The length of the ester fiber is 38mm, the fineness is 1.33dtex,), and 15% tencel; first, a NaOH solution with a concentration of 15g / L is prepared in a container, and 0.4g / L-0.6g / L of dodecane is added therein dimethyl benzyl ammonium chloride cationic surfactant, and then use an electric heating constant temperature water bath, set the temperature of the water bath to 100 °C; then place the container of the prepared NaOH solution in the water bath, and mix the blended fabric Put it in the container for alkali reduction treatment for 30 minutes.

[0020] Under the same post-treatment temperature and treatment time, as the concentration of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com