Construction method for treating rock mass cavity without formworks in tunneling

A technology for tunnel engineering and construction methods, applied in tunnels, tunnel linings, earth-moving drilling and mining, etc., can solve the problems of rockfall, easy occurrence of danger, large amount of engineering, etc., to ensure the quality of treatment, reduce construction risks, and low construction risks. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

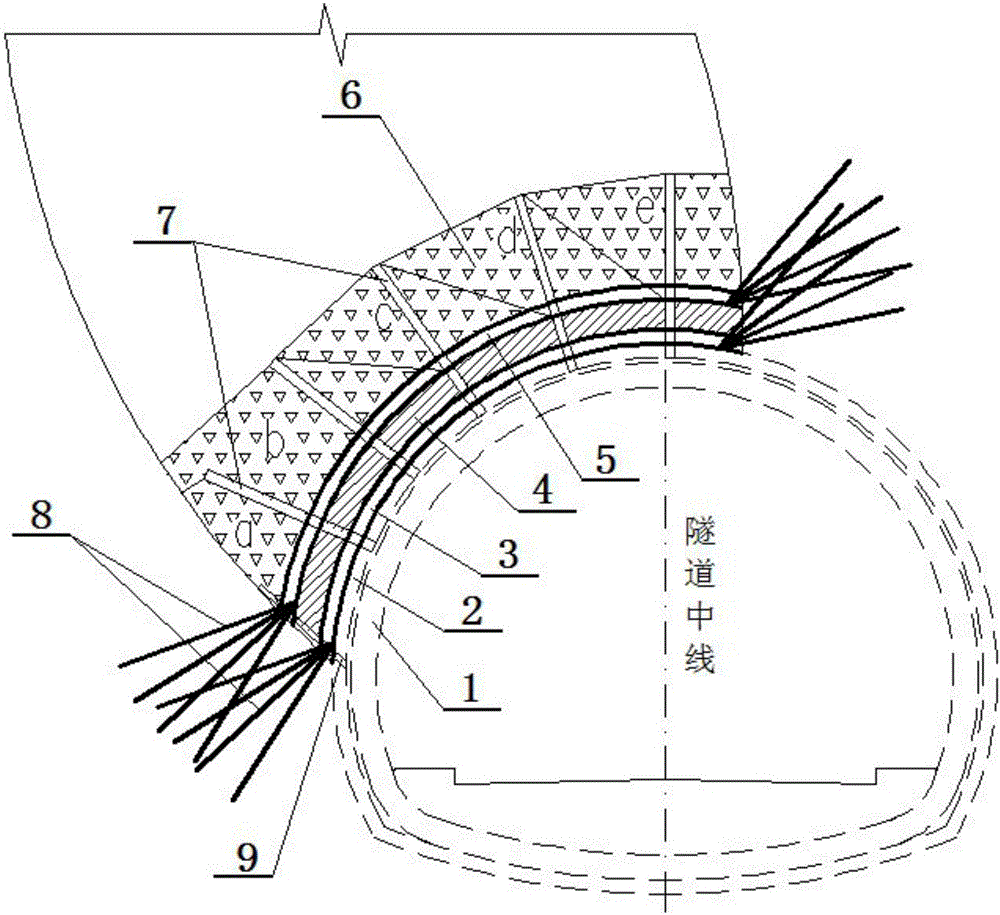

[0033] A construction method for treating a rock mass cavity without templates in tunnel engineering, comprising the following steps:

[0034] Step 1, setting inner and outer protective layers;

[0035]Use PVC waterproof board + φ8 steel mesh 15cm, cooperate with the supporting steel frame 150cm made of I20a steel frame, arrange at the intersection of rock mass cavity and tunnel chamber, and then spray on PVC waterproof board + steel mesh and supporting steel frame C20 concrete, after the concrete is solidified, check the shotcrete layer, and add shotcrete to the gaps and thinner parts to form an outer protective layer with a thickness of 20cm; use the same construction steps to apply an inner protective layer with a thickness of 15cm on the inner side of the outer protective layer; The distance between the inner and outer protection layers is 70cm; both the outer protection layer and the inner protection layer are equipped with drain holes and blow-fill holes, and are pre-bur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com