Fibonacci spiral water turbine using tidal current energy for generating electricity

A spiral, tidal energy technology, applied in ocean energy power generation, reaction engine, hydroelectric power generation, etc., can solve the problems of poor economy, low efficiency of the whole machine, low efficiency and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

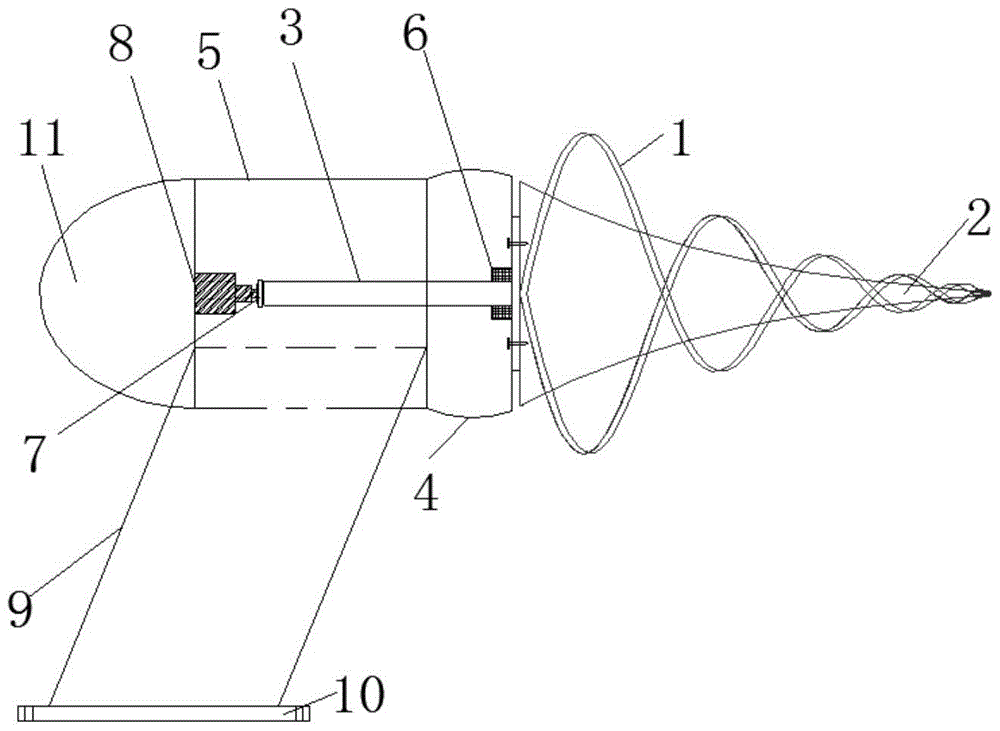

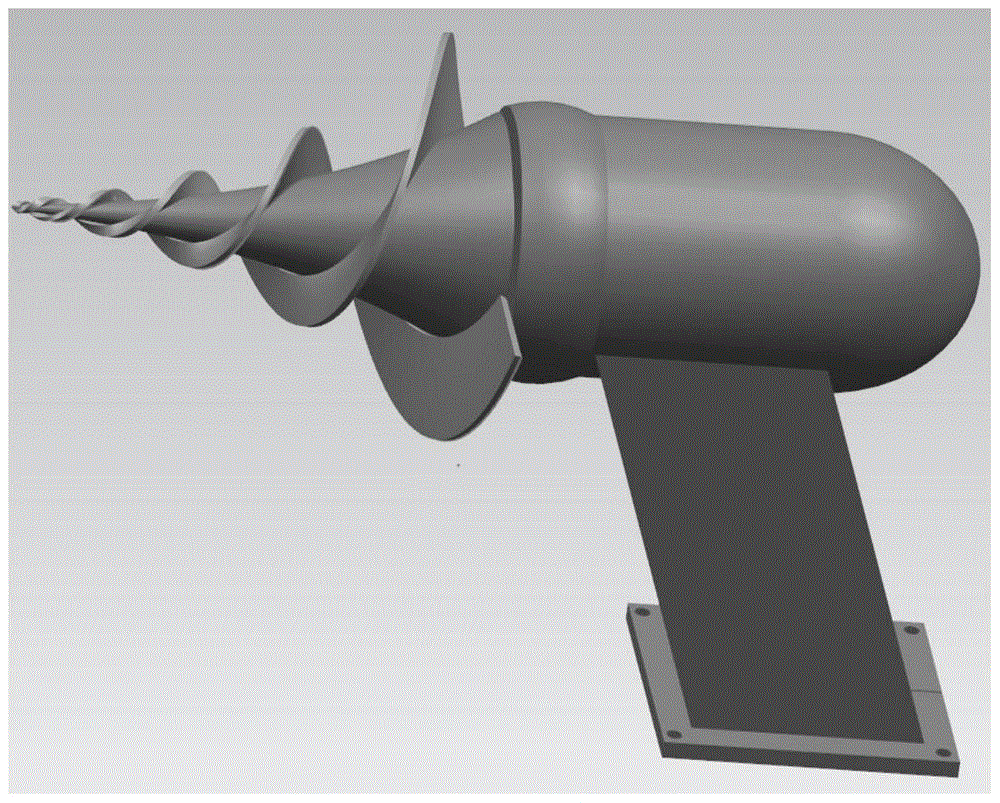

[0097] The design scheme of embodiment 1 is exactly the same as the above-mentioned technical scheme of the present invention, and the design parameters of its main components are disclosed as follows:

[0098] The quantity of spiral blade (1) of the present invention is 2 pieces; The section shape of spiral blade (1) selects symmetrical airfoil; The height of spiral blade (1) is 310cm, maximum diameter is 190cm, and minimum pitch is 85cm , The pitch gradient ratio is 5:6; the height of the conical hub (2) is 310cm, and the maximum diameter is 105cm; the height of the water guide cone (11) is 180cm, and the diameter is 105cm.

Embodiment 2

[0099] The design scheme of embodiment 2 is exactly the same as the above-mentioned technical scheme of the present invention, and the design parameters of its main components are disclosed as follows:

[0100] The quantity of helical blade (1) of the present invention is 1 piece; The section shape of helical blade (1) selects asymmetric airfoil; The height of helical blade (1) is 320cm, maximum diameter is 220cm, and minimum pitch is 85cm, the pitch gradient ratio is 5:6; the height of the quasi-conical hub (2) is 320cm, and the maximum diameter is 105cm; the height of the water guide cone (11) is 190cm, and the diameter is 105cm.

Embodiment 3

[0101] The design scheme of embodiment 3 is exactly the same as the above-mentioned technical scheme of the present invention, and the design parameters of its main components are disclosed as follows:

[0102] The quantity of spiral blade (1) of the present invention is 5 pieces; The section shape of spiral blade (1) selects symmetrical airfoil; The height of spiral blade (1) is 320cm, maximum diameter is 150cm, and minimum pitch is 105cm , The pitch gradient ratio is 5:6; the height of the quasi-conical hub (2) is 320cm, and the maximum diameter is 105cm; the height of the water guide cone (11) is 160cm, and the diameter is 105cm.

[0103] The specific application process of the present invention is as follows: the runner of the present invention includes a helical blade (1) and a conical hub (2) in cooperation, when the tidal current in the ocean impacts the helical blade (1) of the runner, the The spiral blades (1) of the wheel convert the energy of the tidal current into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pitch | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com