Combined salt-spray corrosion test box

A salt spray corrosion and test chamber technology, applied in the direction of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of waste of resources, uneven spray, inability to centralize control, etc., to improve the degree of automation and easy operation Simple, easy to transport and install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

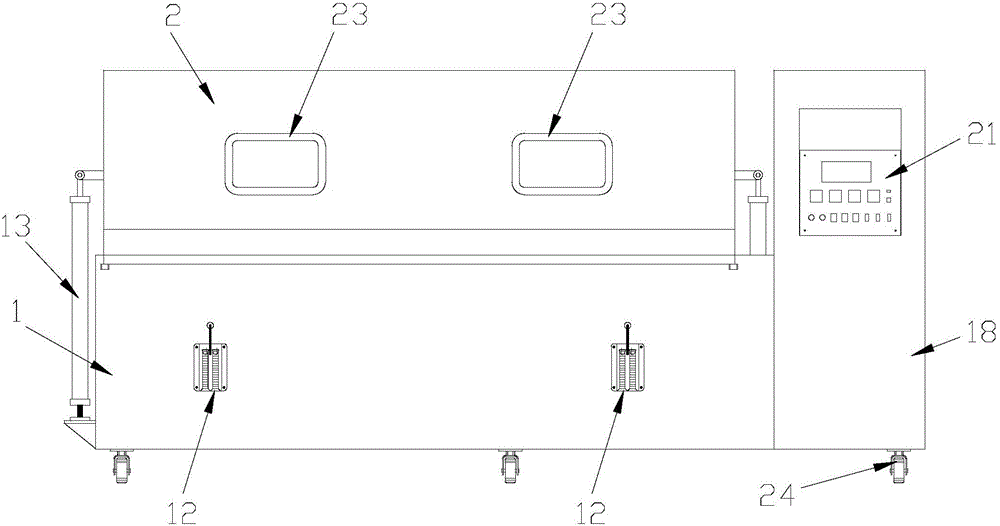

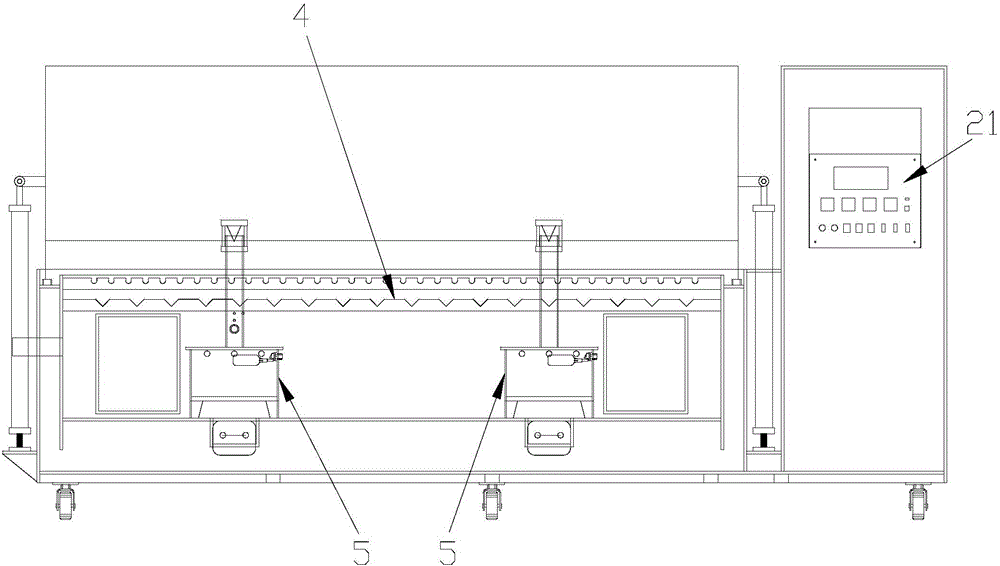

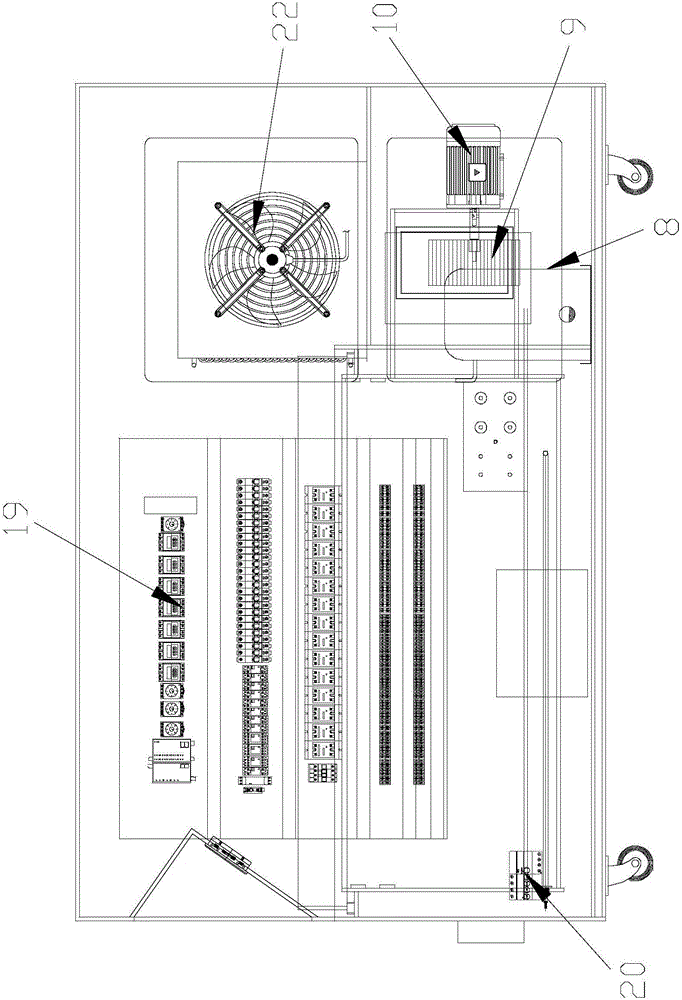

[0034] As shown in the drawings, the present invention includes: a box body 1, a spray system, a defogging system and an electrical system, the box body 1 is provided with a box cover 2, the box body 1 is provided with a working room 3, and the working room 3 is provided with The sample rack 4, the spraying system includes a spray tower 5, a brine tank 6 and a saturated bucket 7, the spray tower 5 is provided with a nozzle, the water inlet of the nozzle is connected to the water outlet of the peristaltic pump through a pipeline, and a valve is installed at the water inlet of the nozzle, and the peristaltic pump The water inlet is connected to the water outlet of the brine tank 6 through a pipeline. A glass filter is installed on the pipeline between the nozzle and the brine tank 6. The air inlet of the nozzle is connected to the outlet of the saturated barrel 7 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com