A high-altitude stamping rotary tower type rapid salt brine evaporation treatment equipment

A technology for processing equipment and brine, applied in evaporation, evaporator accessories, chemical instruments and methods, etc., can solve the problems of long cycle of extracting important elements from brine ponds, passive use of manpower, and expensive production of brine ponds. The effect of low production efficiency, reduced investment, and increased market value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

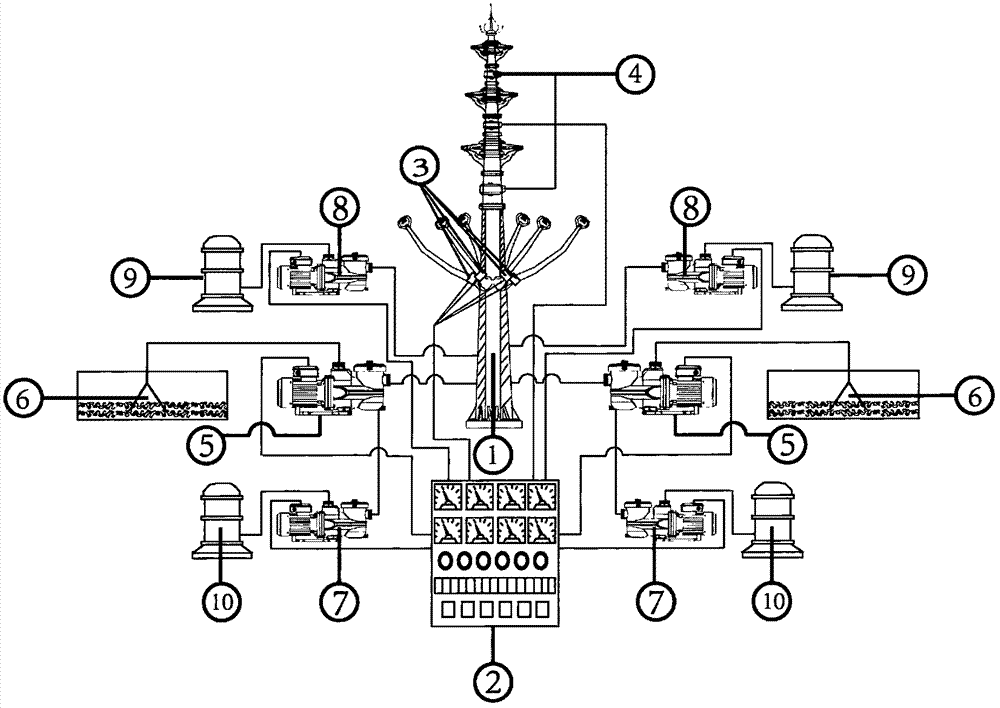

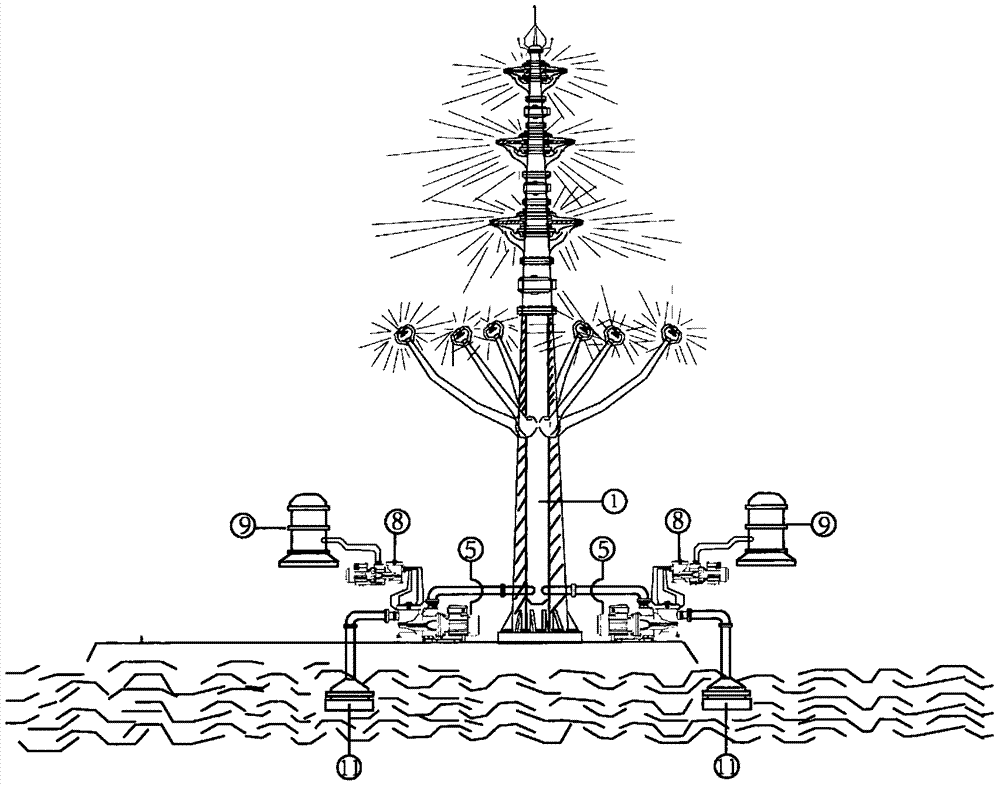

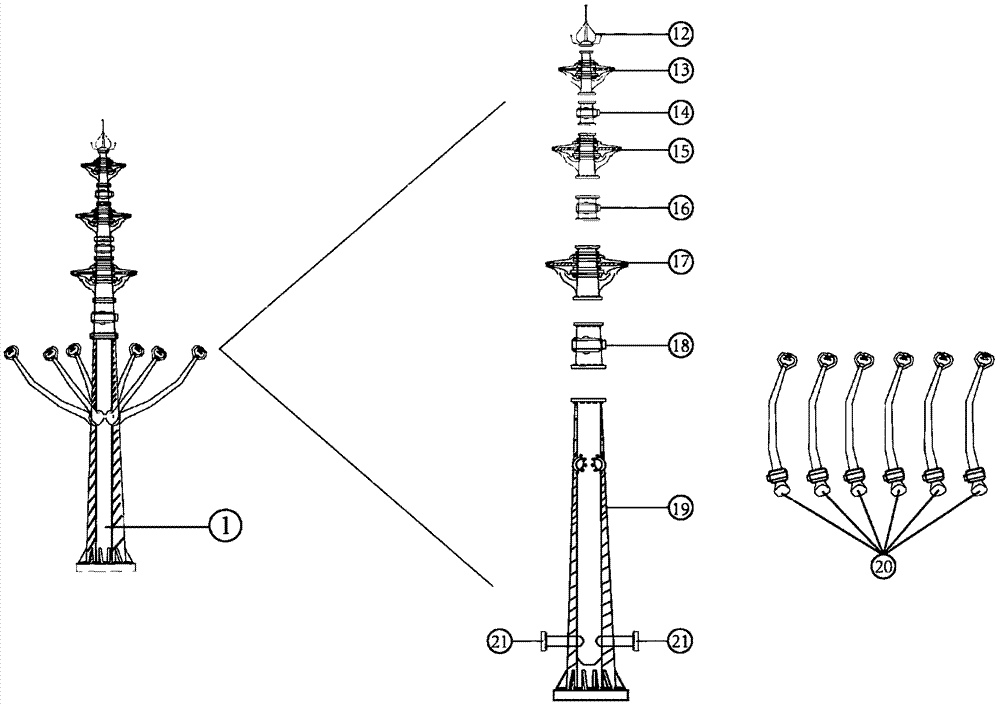

[0044] see Figure 1~2 , in an embodiment of the present invention, a high-altitude stamping rotary tower type rapid salt brine evaporation treatment equipment includes an evaporation tower 1, a main console 2, an electronic valve device A3, an electronic valve device B4, an anti-corrosion high-pressure cleanable water pump 5, an evaporation Pool 6, high-pressure cleaning water pump A7, high-pressure cleaning water pump B8, cleaning tank A9, and cleaning tank B10; evaporation pool 6 is equivalent to a brine evaporation pool, and the traditional method is to introduce seawater or brine into this evaporation pool to be exposed to wind and sun To evaporate the moisture in the brine, the present invention relies on the anti-corrosion high-pressure washable water pump 5 to transport the brine in the evaporation pool 6 to the evaporation tower 1 by pressure, and the evaporation tower 1 is provided with three different levels of centrifugal rotary impact The compass and the lower bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com