Adjustable tray lifting device used for automatic stock bin

A lifting device and pallet technology, which is applied in metal processing and other directions, can solve the problems of difficult position accuracy control, low positioning accuracy, and tolerance, and achieve the effects of accurate positioning position, wide application range, and reduced production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] specific implementation plan

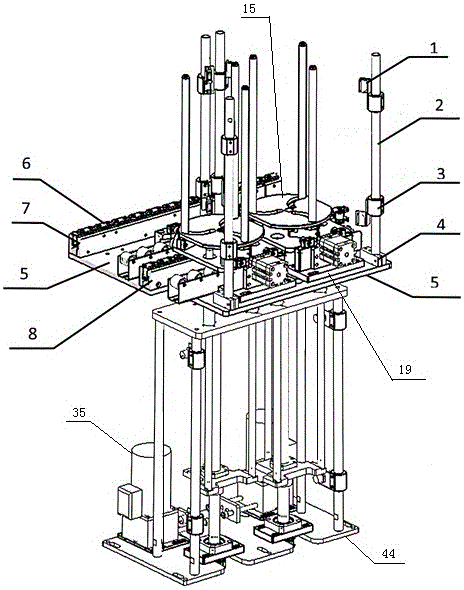

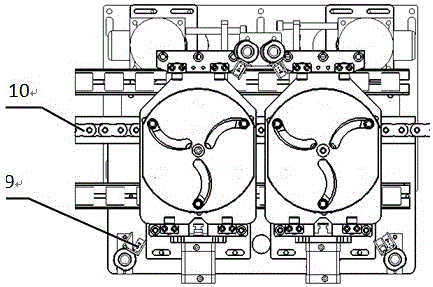

[0022] Attached below Figure 1-7 The present invention is further analyzed.

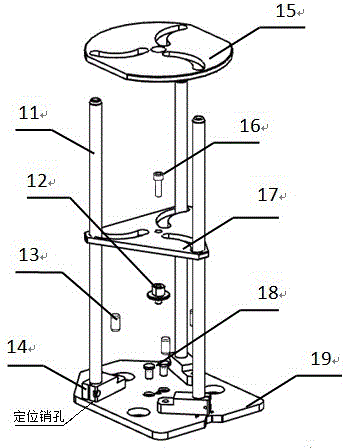

[0023] Such as Figure 1-2 As shown, the adjustable pallet lifting device for automatic bins of the present invention mainly includes three parts: a workpiece clamping mechanism, a pallet positioning mechanism and a pallet lifting mechanism; the workpiece clamping mechanism is as follows: image 3 As shown: the pallet clamping technology with adjustable three-bar guide is adopted. The pallet includes two pin shafts 18 connected to the bottom plate 19, and the lower ends of the pin shafts 18 are connected with the attached plate holes on the chain. Chain drives base plate 19 to realize operation by bearing pin; Described base plate 19 is fixed with nut 12, and the center of described nut 12 is the circle of center of circle and is evenly distributed with three positioning pin holes and three cylindrical pins 13, and on described positioning pin A rotatable str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com