Wheel set cleaning equipment

A technology for cleaning equipment and wheelsets, which is applied to metal processing equipment, used abrasive processing devices, abrasives, etc., and can solve problems such as poor manual processing, corrosion and rust on the surface of parts, and waste of production costs. , to achieve the effect of improving corrosion resistance, reducing labor intensity and improving cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

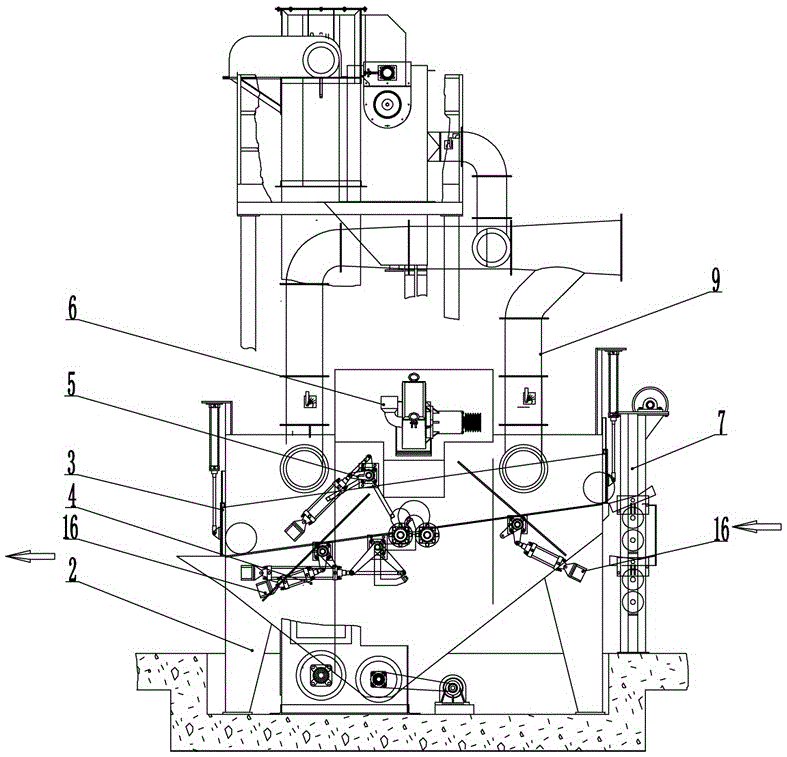

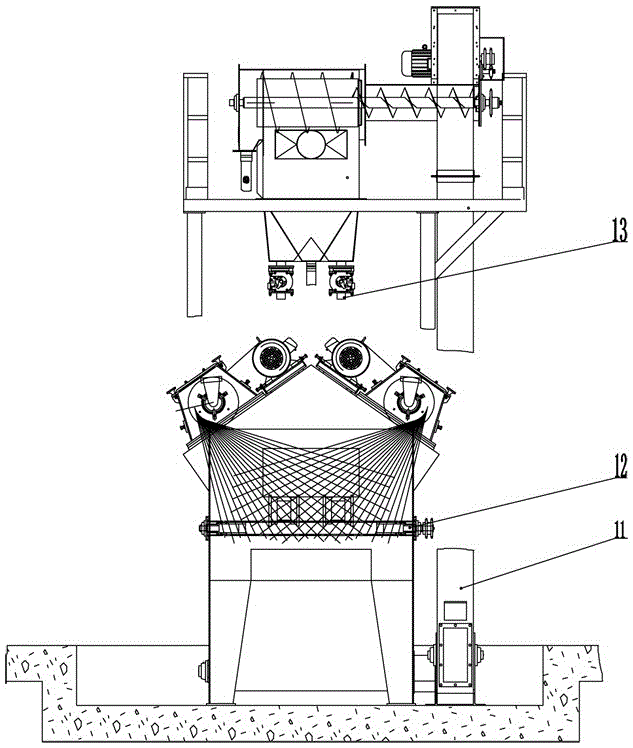

[0013] The wheel set cleaning equipment of the present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0014] As shown in the figure, the wheel set cleaning equipment of the present invention includes a shot blasting chamber 2, a shot blasting device 6 installed on the shot blasting chamber, a door entry plate positioned at the front side of the shot blast chamber, and an exit door plate positioned at the rear side of the shot blast chamber 3. A shot feeding device 13 is arranged above the entrance of the shot blasting device 6; the shot blasting chamber is composed of various chambers, inspection doors, manganese guard plates rolled in the chamber, etc., and the shell of the shot blasting chamber is a steel plate welded structure , is a sealed and spacious operating space for blasting the workpiece; said blasting device 6 is a cantilever centrifugal high-efficiency blasting device, preferably two bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com