Device and method for molding thermoset liquid insulation material by casting

A technology of liquid insulation and casting molding, which is applied in the field of high voltage and insulation. It can solve problems such as uneven thickness, material performance error, and difficult to eliminate, and achieve the effect of uniform material thickness, smooth surface and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

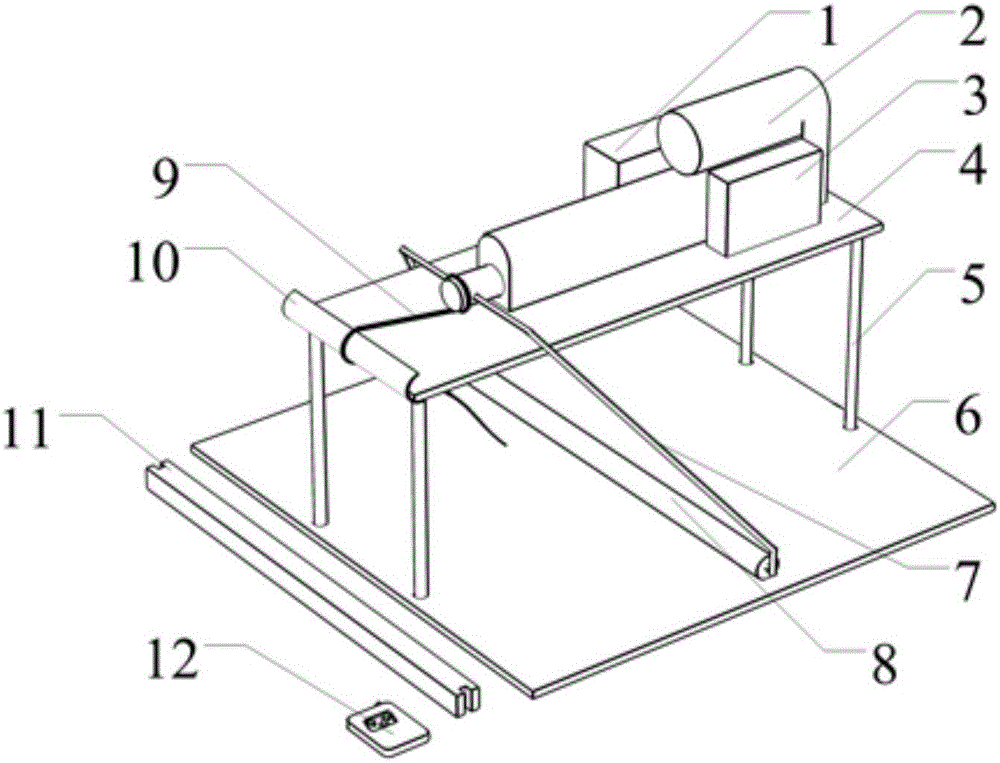

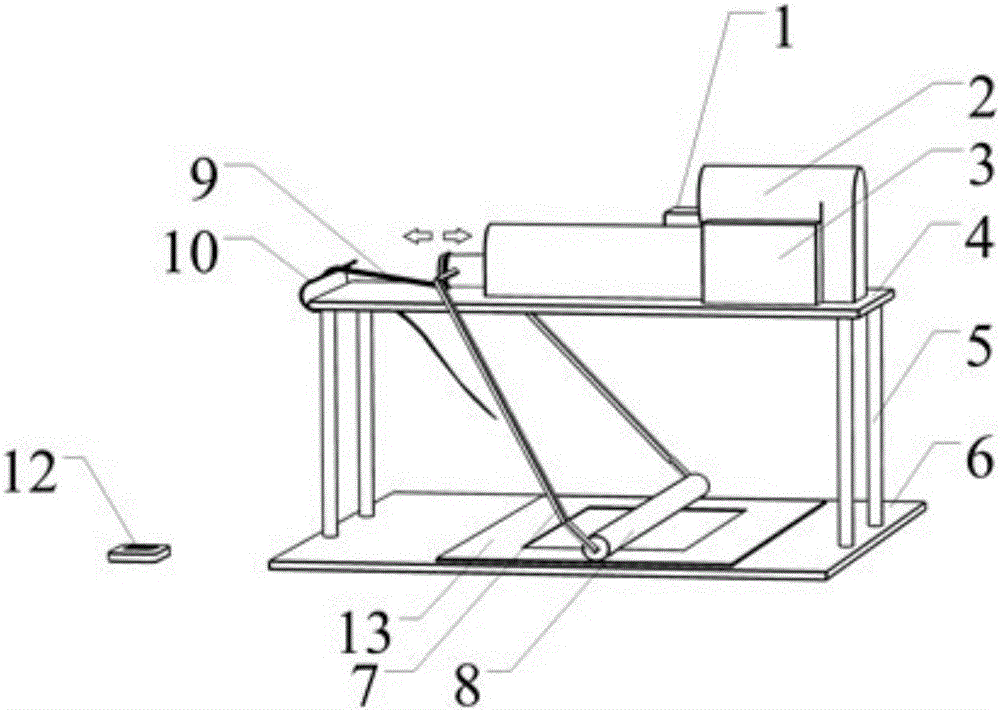

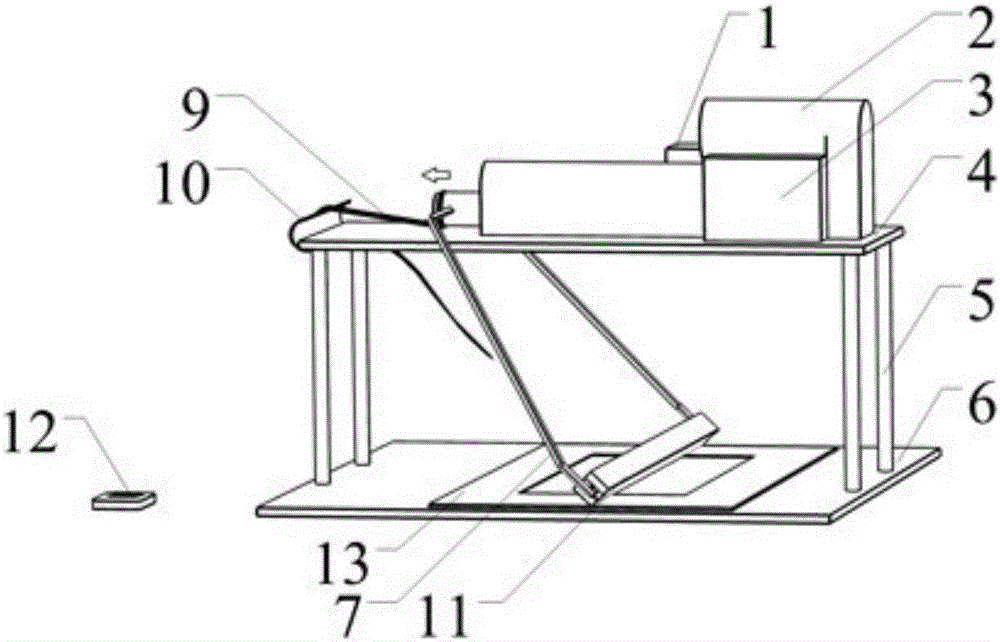

[0021] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

[0022] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a thermosetting liquid insulating material casting molding device includes a DC power supply 1, a mold 13, and the mold 13 is used to put the thermosetting liquid insulating material, and also includes an electric linear push rod 2, a remote control signal receiver 3, and a bracket Plate 4, bracket lower plate 6, fixture 7, round roller 8, traction rope 9, traction rope elastic device 10, scraping assembly 11, wireless remote control 12, the electric linear actuator 2, remote control signal receiver 3, DC The power supply 1 and the traction rope elastic device 10 are all fixed on the bracket upper plate 4, one end of the clamp 7 is connected with the electric linear push rod 2, and the other end of the clamp 7 is detachable with the round roller 8 or the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com