Production method of high-purity strontium carbonate special for light-emitting material

A high-purity strontium carbonate, production method technology, applied in the direction of strontium carbonate, calcium carbonate/strontium/barium, etc., can solve the problems of strontium carbonate morphology, particle size and distribution control, strontium carbonate microscopic morphology, particle size and distribution are in the lab stage etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

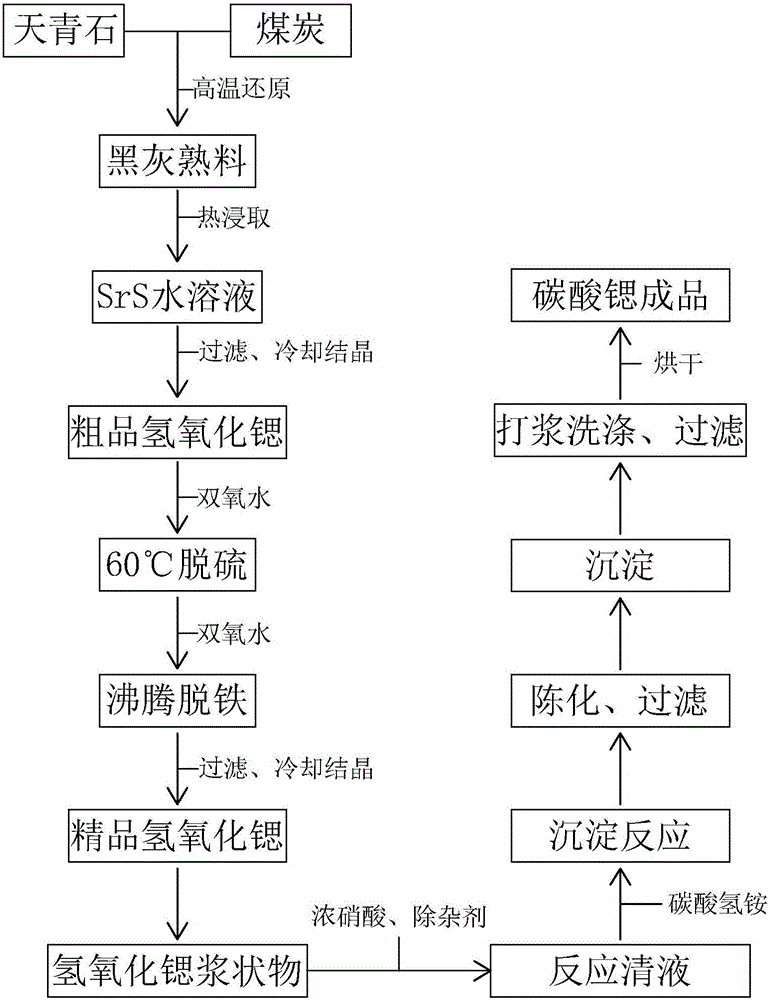

[0029] Method for producing high-purity strontium carbonate special for luminescent materials

[0030] 1. Preparation of strontium hydroxide:

[0031] a, SrSO 4 Celestite with a content of ≥70% and coal with a C content of ≥65% are mixed at a weight ratio of 1:0.35, preheated, and reduced at a high temperature above 1200°C to obtain black ash clinker with a soluble SrS content of 50%;

[0032] b. Leach the black ash clinker with internal circulating process water above 85°C under airtight conditions for 4 hours to obtain an aqueous solution of strontium sulfide with a SrS concentration of 90g / L; quickly filter the aqueous solution of strontium sulfide to remove impurities and decalcify Iron removal

[0033] c. Cool the strontium sulfide aqueous solution to crystallize in the crystallization tank, control the stirring speed 40r / min, and the cooling rate at 24 hours. After the temperature of the strontium sulfide aqueous solution is reduced to 40℃, the crude strontium hydroxide product ...

Embodiment 2

[0043] Method for producing high-purity strontium carbonate special for luminescent materials

[0044] 1. Preparation of strontium hydroxide:

[0045] a, SrSO 4 Celestite with a content of ≥70% and coal with a C content of ≥65% are mixed at a weight ratio of 1:0.35, preheated, and reduced at a high temperature above 1200°C in the high temperature section to prepare black ash clinker with a soluble SrS content of 52%;

[0046] b. Leach the black ash clinker with internal circulating process water above 85°C under airtight conditions for 4 hours to prepare an aqueous solution of strontium sulfide with a SrS concentration of 100g / L; quickly filter the aqueous solution of strontium sulfide to remove impurities and decalcify Iron removal

[0047] c. Cool the strontium sulfide aqueous solution to crystallize in the crystallization tank, control the stirring speed 40r / min, and the cooling rate at 25 hours. After the temperature of the strontium sulfide aqueous solution is lowered to 40℃, the...

Embodiment 3

[0057] Method for producing high-purity strontium carbonate special for luminescent materials

[0058] 1. Preparation of strontium hydroxide:

[0059] a, SrSO 4 Celestite with a content of ≥70% and coal with a C content of ≥65% are mixed at a weight ratio of 1:0.35, preheated, and reduced at a high temperature above 1200°C in the high temperature section to prepare black ash clinker with a soluble SrS content of 52%;

[0060] b. Leach the black ash clinker with internal circulating process water above 85°C under airtight conditions for 4 hours to obtain an aqueous solution of strontium sulfide with a SrS concentration of 110g / L; quickly filter the aqueous solution of strontium sulfide to remove impurities and decalcify Iron removal

[0061] c. Cool the strontium sulfide aqueous solution to crystallize in the crystallization tank, control the stirring speed to 40r / min, and the cooling rate at 25 hours. After the temperature of the strontium sulfide aqueous solution is reduced to 36°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com